Efficient treatment process for printing and dyeing waste water

A technology for printing and dyeing wastewater and treatment process, which is applied in textile industry wastewater treatment, biological water/sewage treatment, adsorption water/sewage treatment, etc. Membrane bioreactor has problems such as limited phosphorus removal effect, and achieves the effect of reducing water content, facilitating biodegradation, and good adsorption and flocculation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

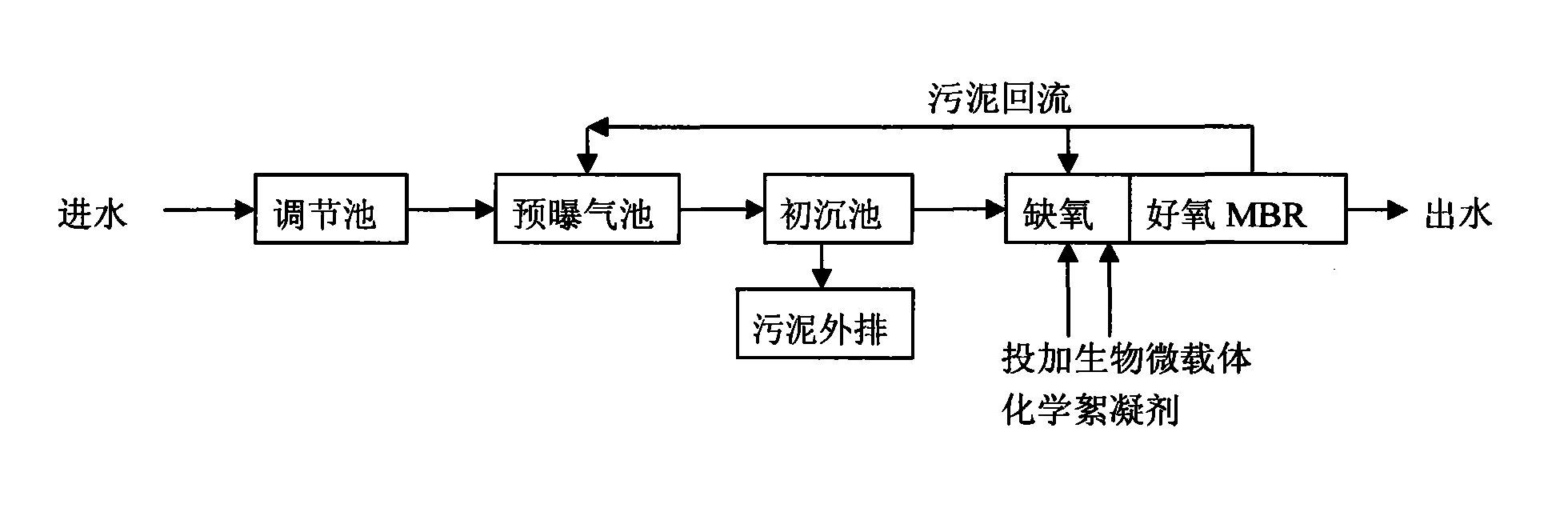

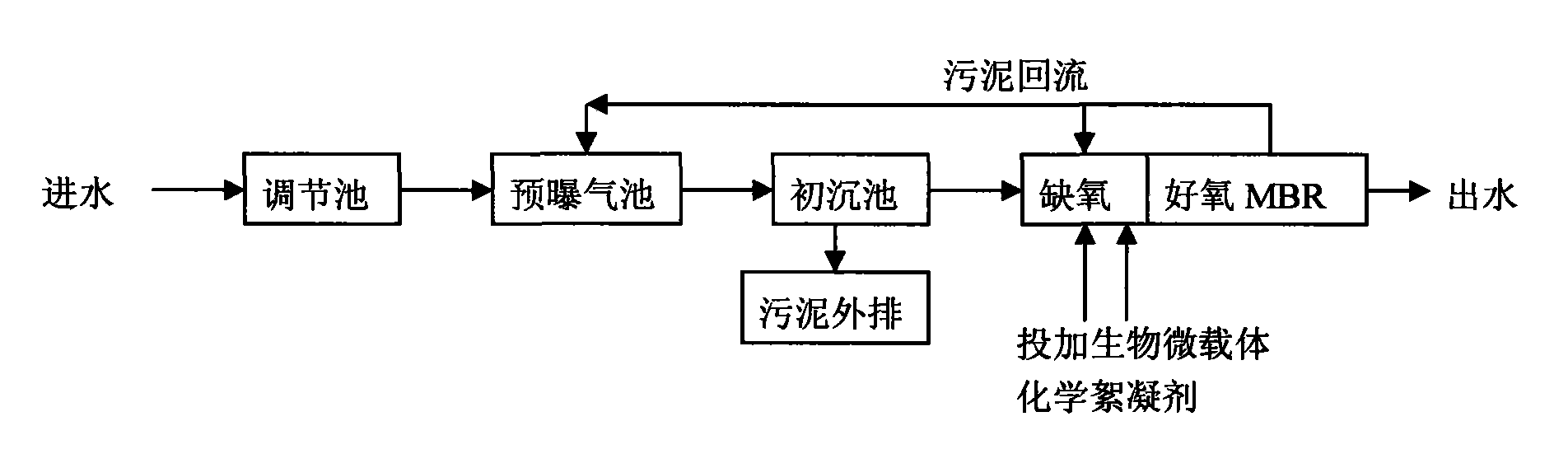

[0025] The printing and dyeing wastewater is firstly treated by pre-aeration after uniform water quality and quantity in the regulating tank. Part of the sludge returned by the MBR is mixed with wastewater in the pre-aeration tank. The pre-aeration effluent enters the primary sedimentation tank for precipitation, the sludge is discharged, and the supernatant enters the anoxic / aerobic membrane bioreactor for biochemical treatment. The residence time of the anoxic / aerobic membrane bioreactor is 32 hours, and the membrane module used is a flat membrane. The membrane flux is 20L / (m 2 .h). Diatomaceous earth and polyaluminum chloride were added into the membrane bioreactor, the dosages were 50mg / L and 20mg / L, respectively. Among them, diatomaceous earth is used as a biological microcarrier with adsorption function. Polyaluminum chloride is used as a flocculant. The sludge age of the control system is 20 days, and the sludge concentration is 5000 mg / L. Aeration is carried out in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com