Waving resistance device in tank truck and tank truck with same

A liquid tank truck and internal resistance technology, which is applied in the direction of tank trucks, packaging, transportation and packaging, etc. It can solve the problems that affect the smooth operation of tank trucks, high fuel consumption, and inability to effectively absorb wave impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

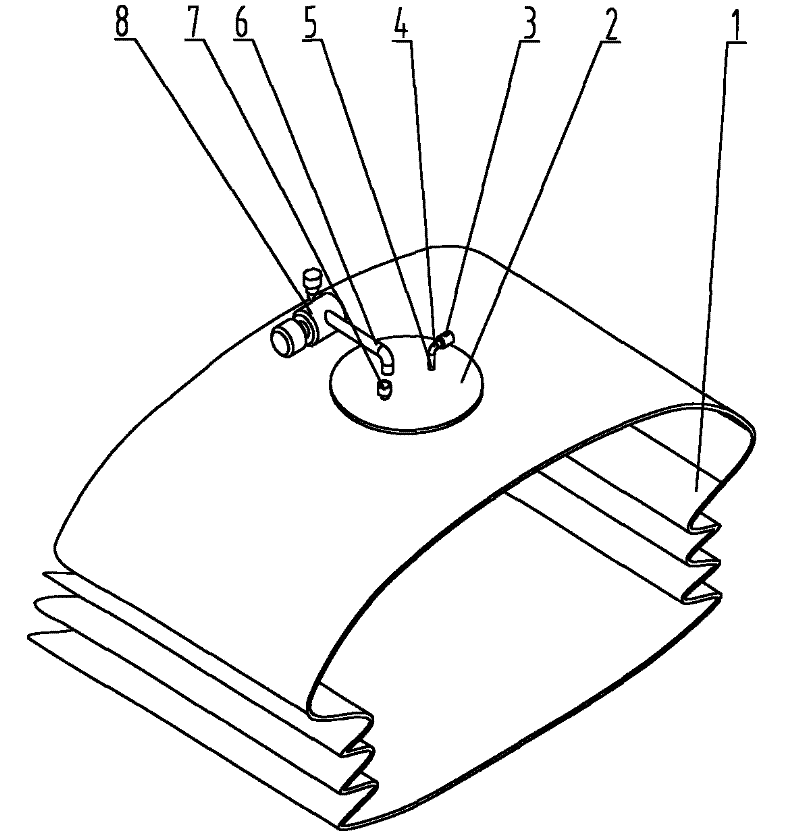

[0016] Such as figure 1 As shown, it is a three-dimensional structural schematic diagram of the wave resistance device in the tank of the liquid tank truck of the present invention. The anti-wave device in the tank of the liquid tanker of the present invention comprises a main body 1 and a fixed seat 2, the fixed seat 2 is arranged on the top of the main body 1, and the fixed seat 2 is provided with an air intake device 21 and an exhaust device 22, The main body 1 is a soft airtight capsule.

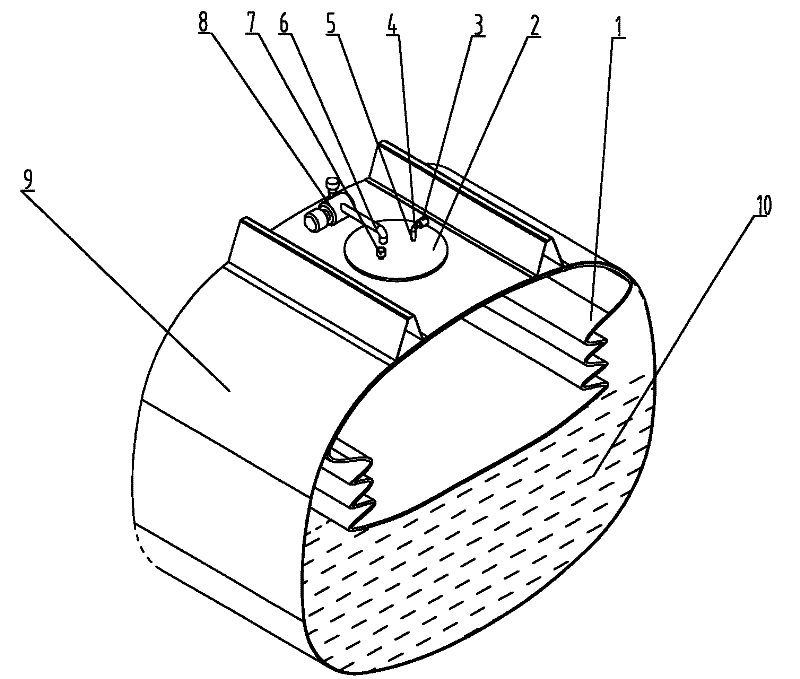

[0017] Such as figure 2 As shown, the exhaust device 22 is an exhaust valve, the exhaust valve 3 is connected to the fixed seat 2 through an exhaust pipe 4 , and a pressure detection sensor 5 is arranged in the exhaust pipe 4 . The air intake device 21 is an air pump 8 , and the air pump 8 is connected to the fixed seat 2 through an air tube 6 . A safety valve 23 is also arranged on the fixed seat 2 . The main body 1 is made of organic flexible material, rubber material or airtight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com