Chlorination reaction device

A technology of chlorination reaction and chlorination reactor, which is applied in the field of chlorination reaction device, can solve the problems of low material reaction efficiency, insignificant environmental protection effect, high price of equipment and materials, and achieve good resistance to high temperature oxidation, ideal strength, resistance Good oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

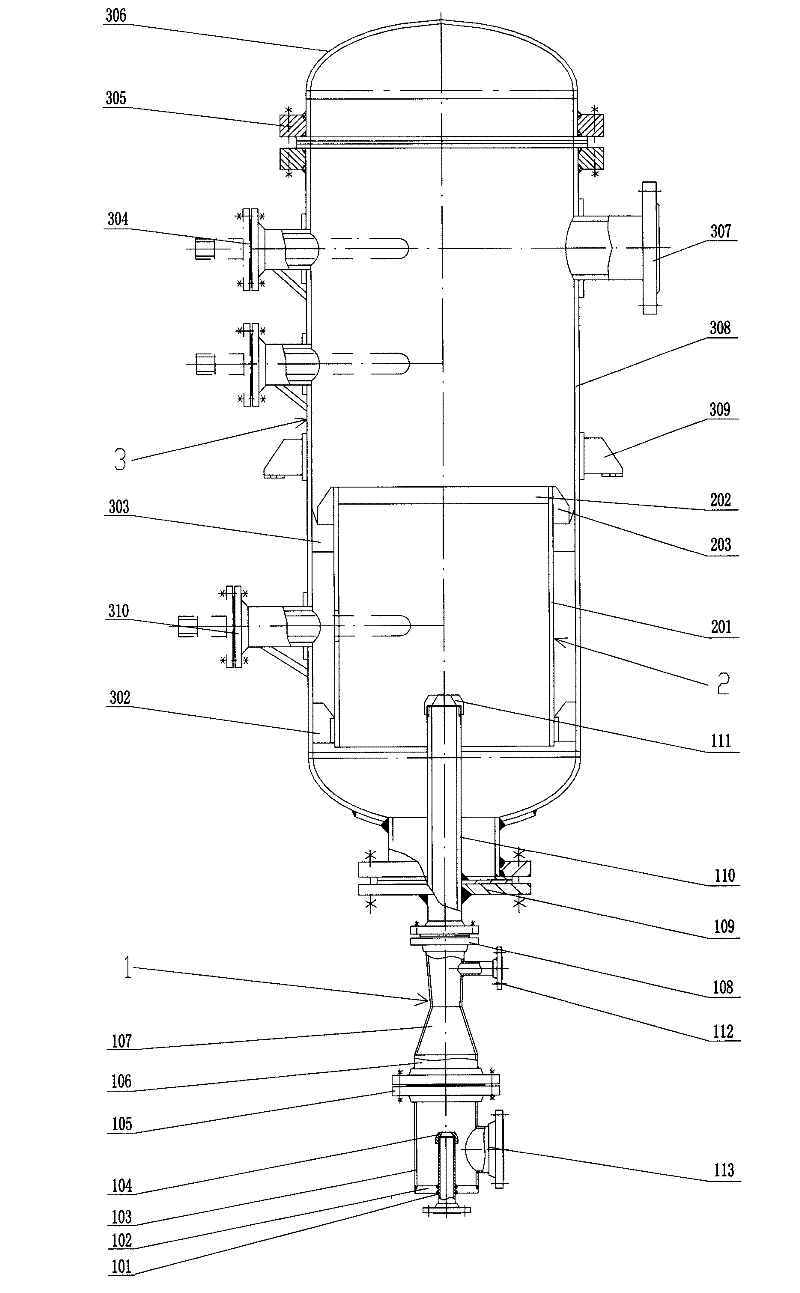

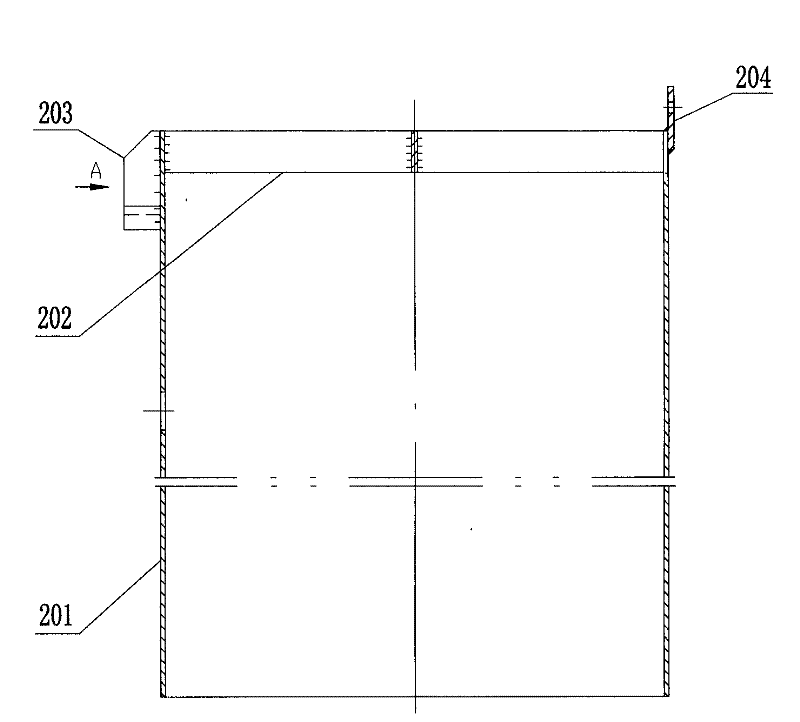

[0024] Such as figure 1 As shown, the chlorination reaction device is composed of a jet mixer 1, an inner guide tube 2, and a chlorination reactor 3. The jet mixer 1 and the chlorination reactor 3 are fixedly connected by an equipment flange 109, and the inner guide tube 2 Placed in the chlorination reactor 3.

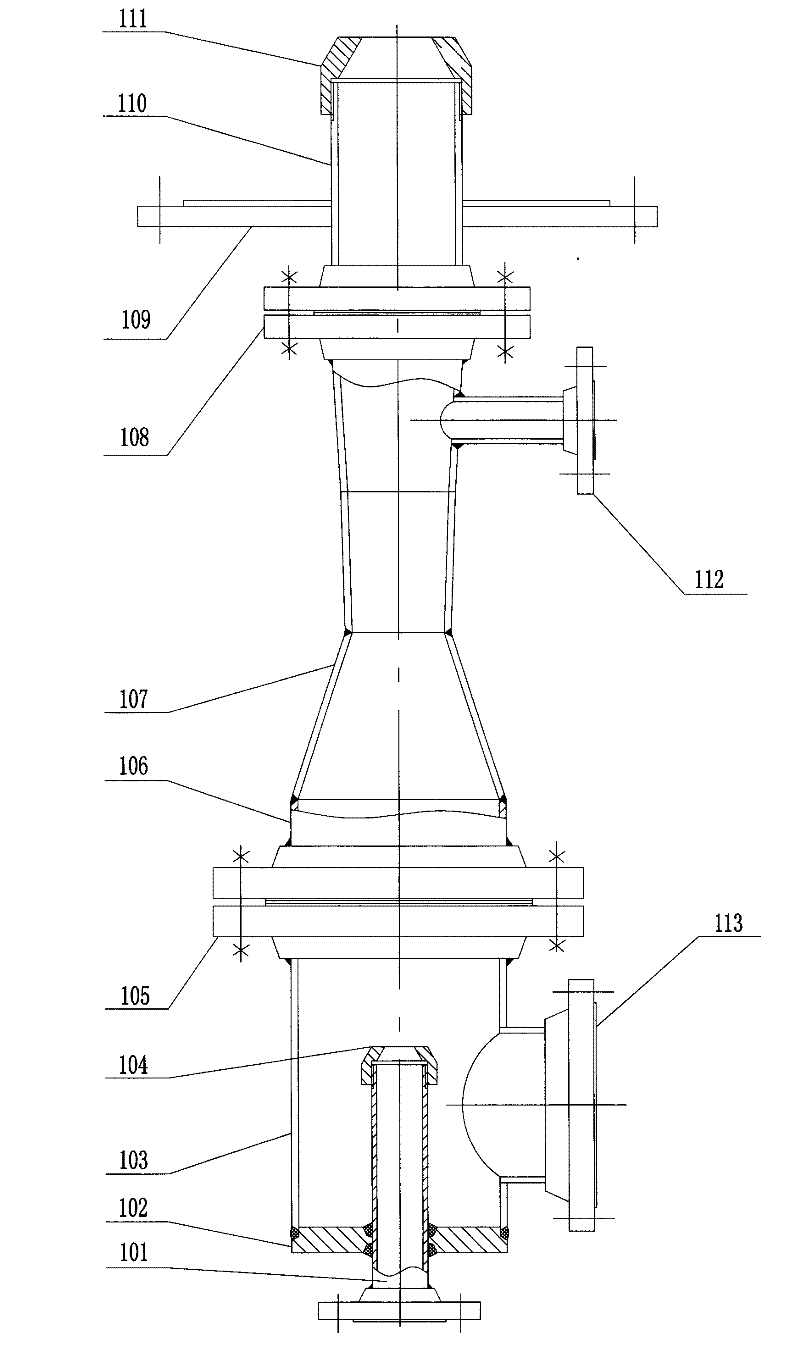

[0025] Such as figure 2 As shown, the jet mixer 1: the material cavity is composed of the chlorine gas inlet pipe 101, the flat cover 102, the cylinder I 103, the nozzle I 104 and the mixed gas inlet pipe 113, and the chlorine gas inlet pipe 101 passes through the flat cover 102 and is inserted into the cylinder I 103 Inside, the diameter of the outlet side of the nozzle I 104 is φ80, the cylinder I 103 is connected to the short joint 106 through the flange 105, the short joint 106 is connected to the variable diameter section 107, and the temperature measuring port I 112 is provided on the variable diameter section 107. The diameter section 107 is connected to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com