Oblique strain power transmission iron tower

A technology of transmission towers and towers, which is applied in the field of corner-type and terminal-type transmission towers, can solve the problems of heavy tension-resistant transmission towers, and achieve the effect of optimizing the stress system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A specific example of the present invention will be described in detail below in conjunction with the accompanying drawings, the impact of the use of inclined tension-type power transmission towers on the force on the tower.

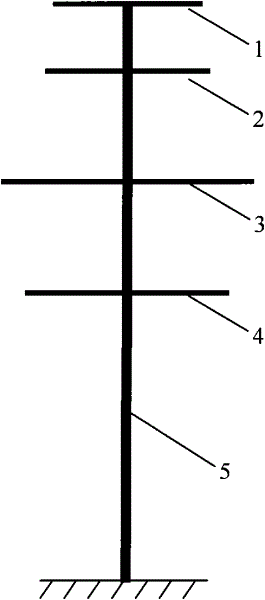

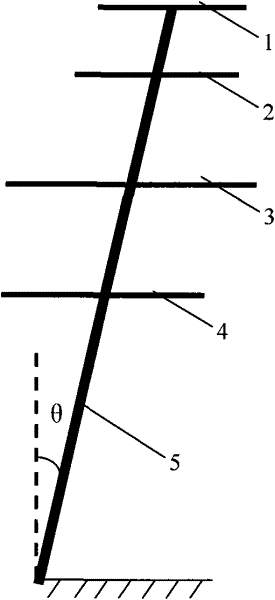

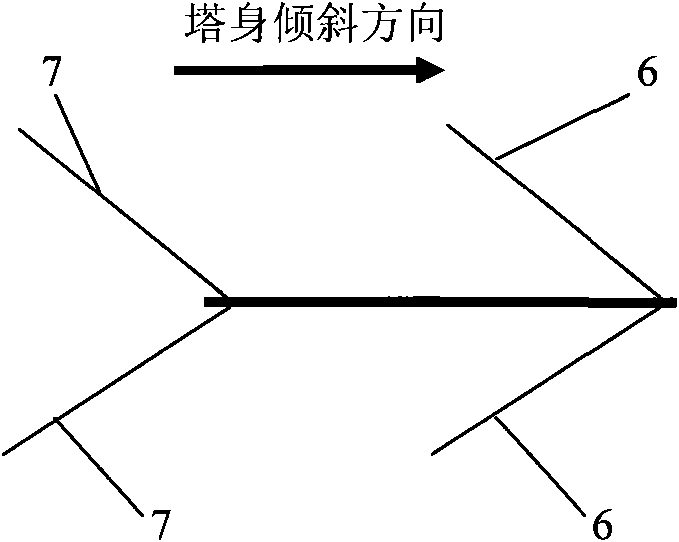

[0015] like Figure 2A As shown, in order to facilitate construction, in the inclined tension-resistant transmission tower of the present invention, the ground wire cross arm 1, the upper wire cross arm 2, the middle wire cross arm 3 and the lower wire The crossarms 4 are arranged horizontally, and the tower body 5 is inclined and forms an included angle θ with the vertical direction. like Figure 2B As shown, the inclination direction of the tower body is the direction opposite to the extension direction of the front and rear side wires 6 and 7 along the direction of the cross arm, that is, the inclination direction of the tower body is the direction indicated by the arrow in the figure.

[0016] Figure 3 is a schematic diagram of the force of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com