Enclosed hollow tube element

A hollow tube and component technology, which is applied to building components, on-site preparation of building components, structural elements, etc., can solve problems such as unreliable lap joints at joints, low strength and integrity of hollow tube components, and difficult joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

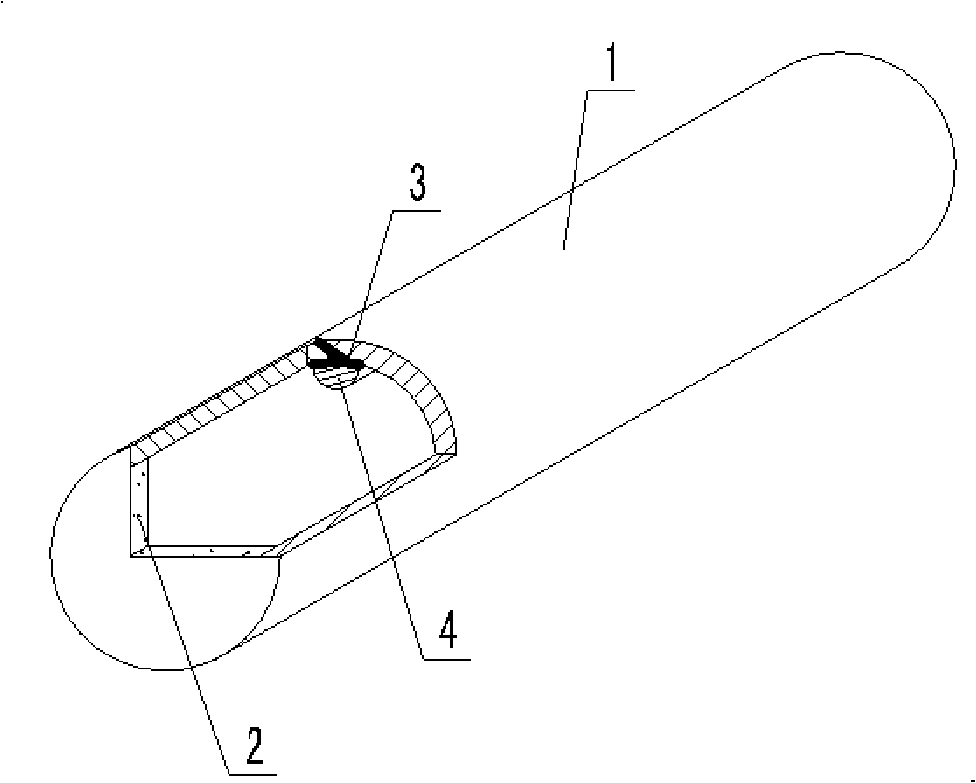

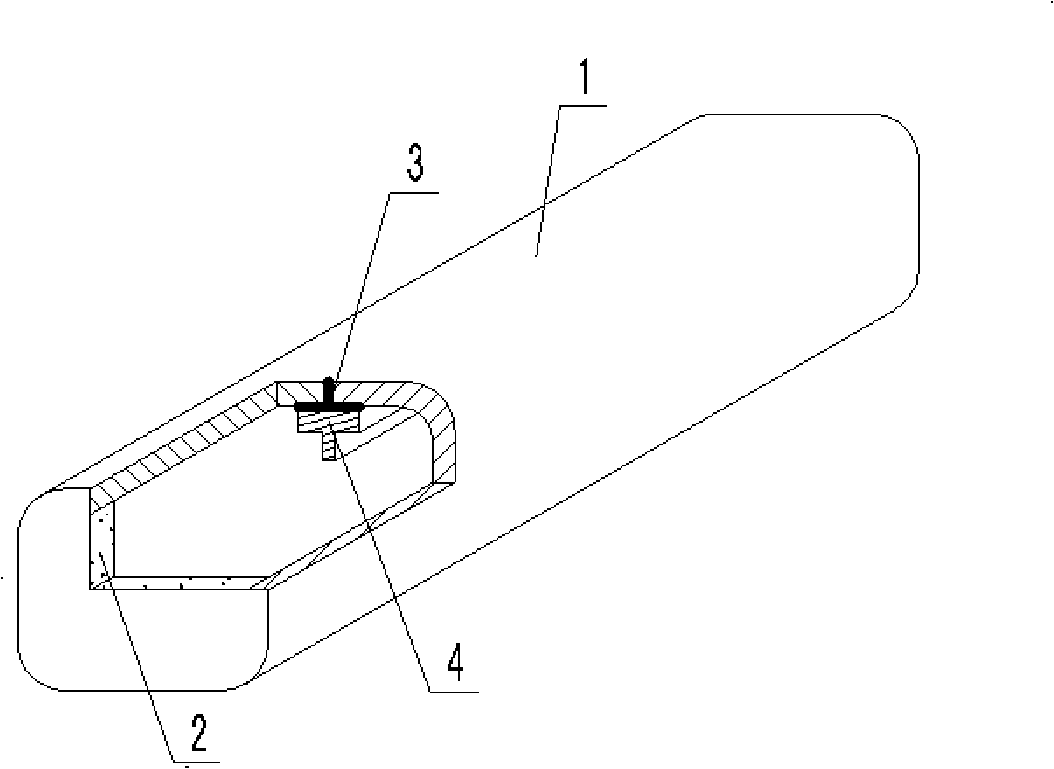

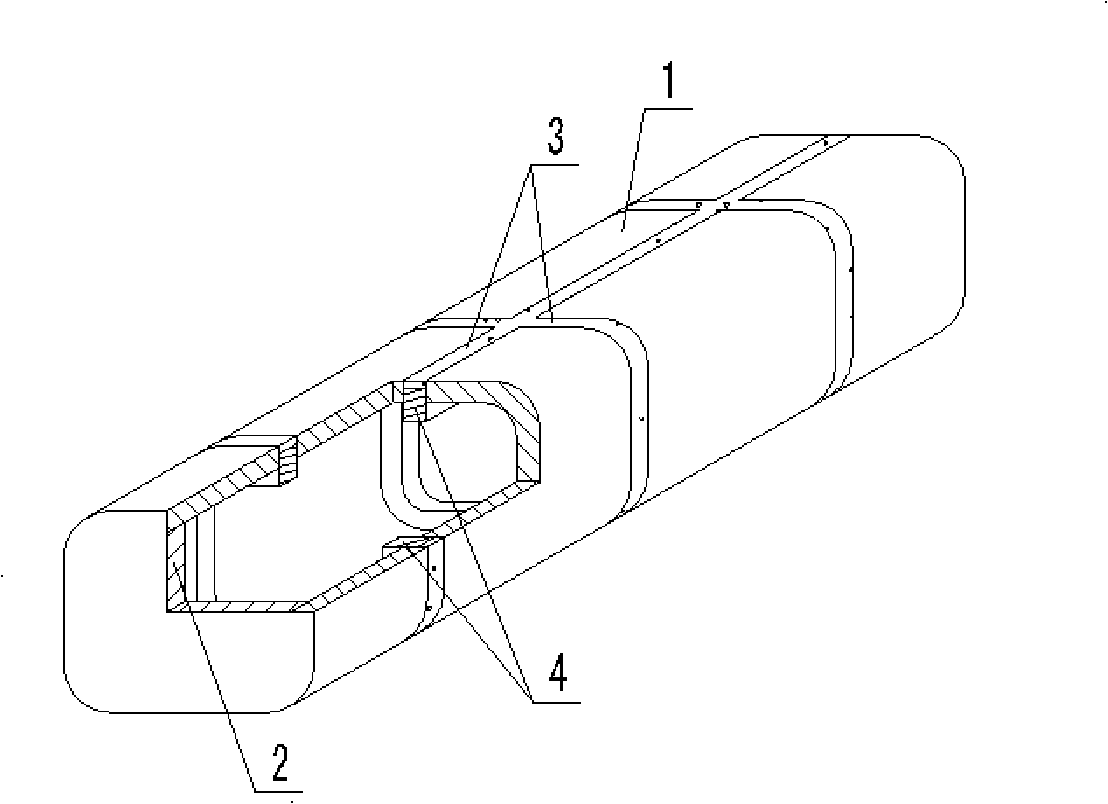

[0052] As shown in the accompanying drawings, the present invention includes a pipe body 1, a pipe end seal 2, and the pipe end seal 2 closes the pipe body 1 to form a closed hollow pipe. The seam 3 is characterized in that there is a prefabricated support member 4 that is superimposed and glued with the joined embryo body at the joint part of the embryo body of at least one joint seam 3. The support member 4 is strip-shaped, flat, At least one of arc plate, T-shaped plate, V-shaped plate, rib, stiffened rib, horizontal bar, vertical bar, bar with plate or stiffened rib with plate, and the joint 3 is a blank Body lap joint cementation or embryo body butt joint cementation or embryo body partial lap joint part butt joint cementation joint joint, said pipe body 1 is provided with at least one of rods 6, stiffening ribs 7 or ribs 8, and the rods Part 6, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com