Expanded-base pre-buried anchoring structure

An anchoring structure and pre-embedded technology, which is applied in the direction of building components, building structures, walls, etc., can solve the problems that the pre-embedded board and formwork cannot be tightly combined, the effect of lightning protection is affected, and the curing time is long. Achieve the effect of eliminating fire hazards and electrical safety hazards, reducing labor and material costs, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

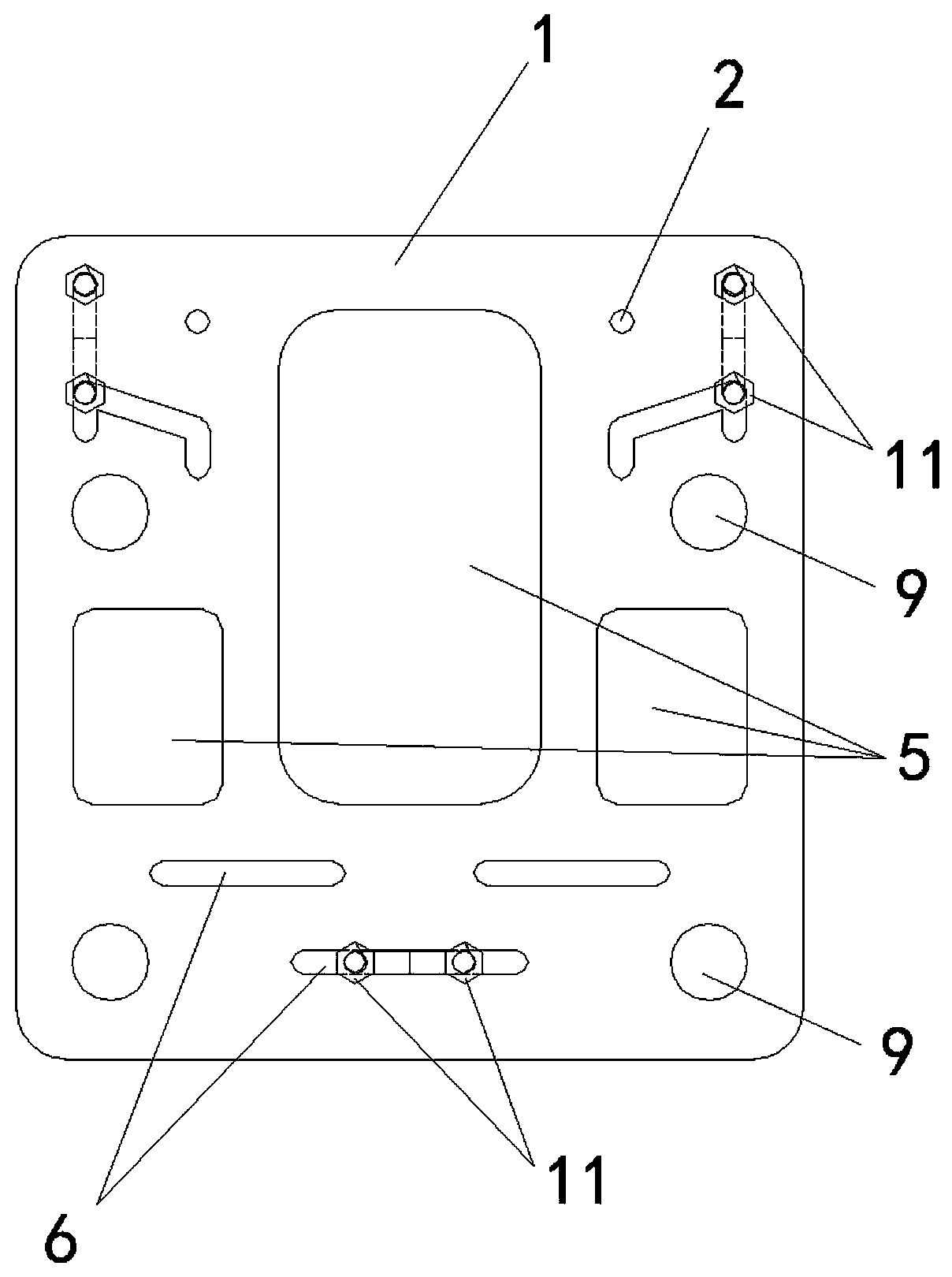

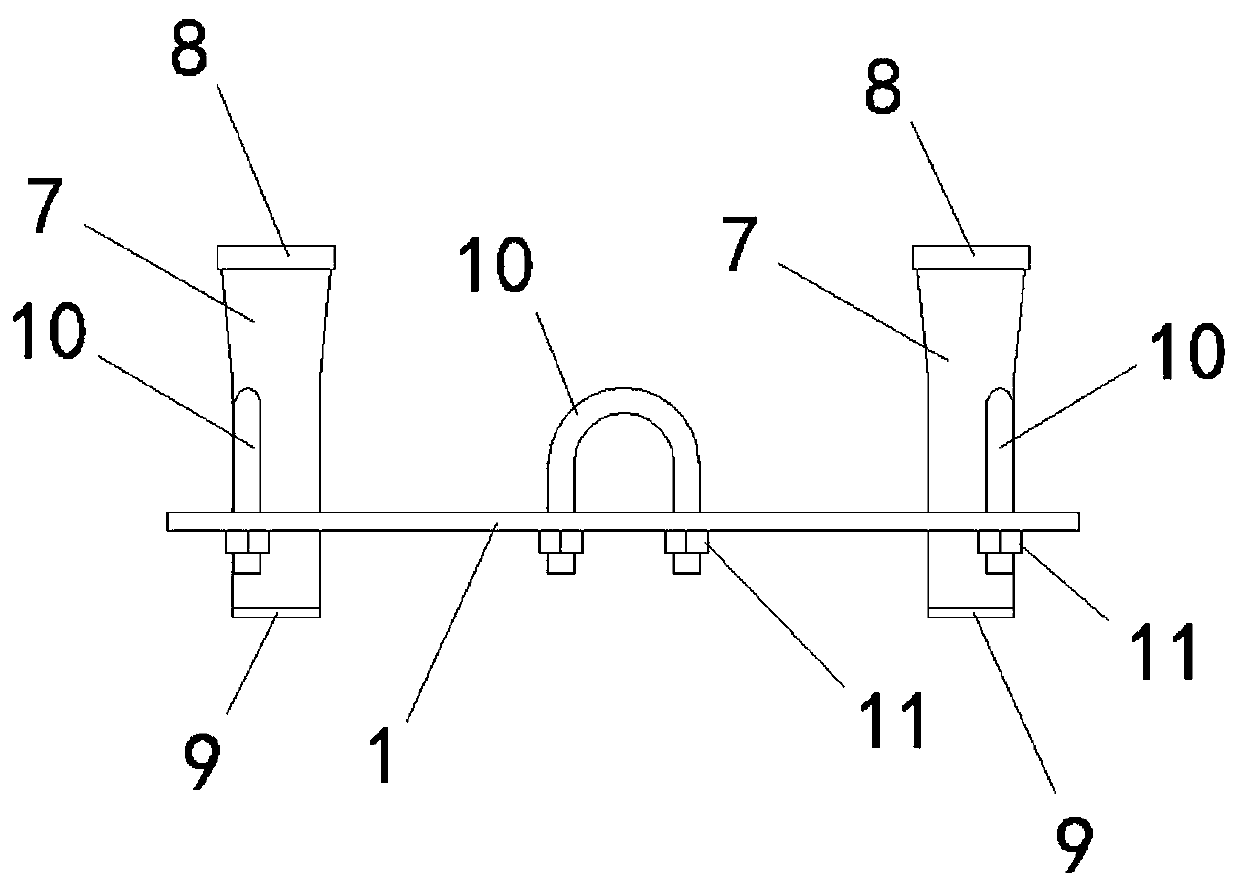

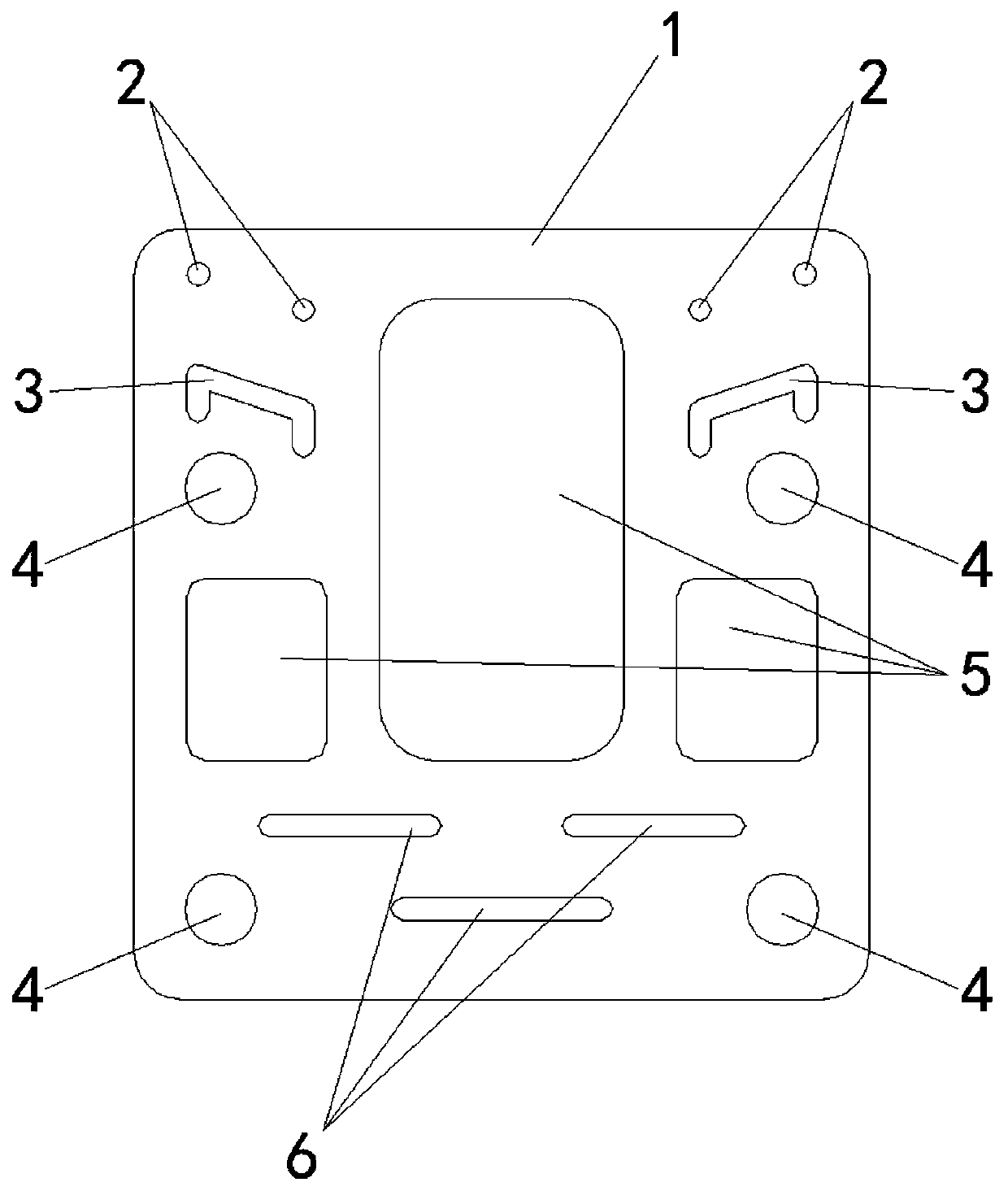

[0016] Such as Figure 1-5 Shown: the pre-embedded anchoring structure of the present invention includes a connecting plate 1, first bolt holes 2 are symmetrically arranged on both sides of the upper part of the connecting plate 1, and second bolts are arranged on the lower connecting plate 1 of the first bolt hole 2 The hole 3 is provided with a third bolt hole 6 at the bottom of the connecting plate 1 . Between the first bolt hole 2 and the second bolt hole 3, the third bolt hole 6 is equipped with bent bolts 10, that is, U-shaped bolts (such as Figure 5 ). The end of bending bolt 10 is equipped with flat washer, spring washer, nut 11. The matching bent bolts 10 between the first bolt hole 2 and the second bolt hole 3 are arranged vertically, and the matched bent bolts 10 of the third bolt hole 6 are arranged horizontally.

[0017] Such as image 3 , 4 As shown: there are at least four evenly distributed tube holes 4 on the connecting plate 1, the sleeve 7 includes a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com