Compounded rubber vertical type storage tank conical bottom board and its manufacture method

A composite rubber, vertical storage tank technology, applied in building types, buildings, large-capacity bulk material storage, etc. The effect of stress system, prolonging service life and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

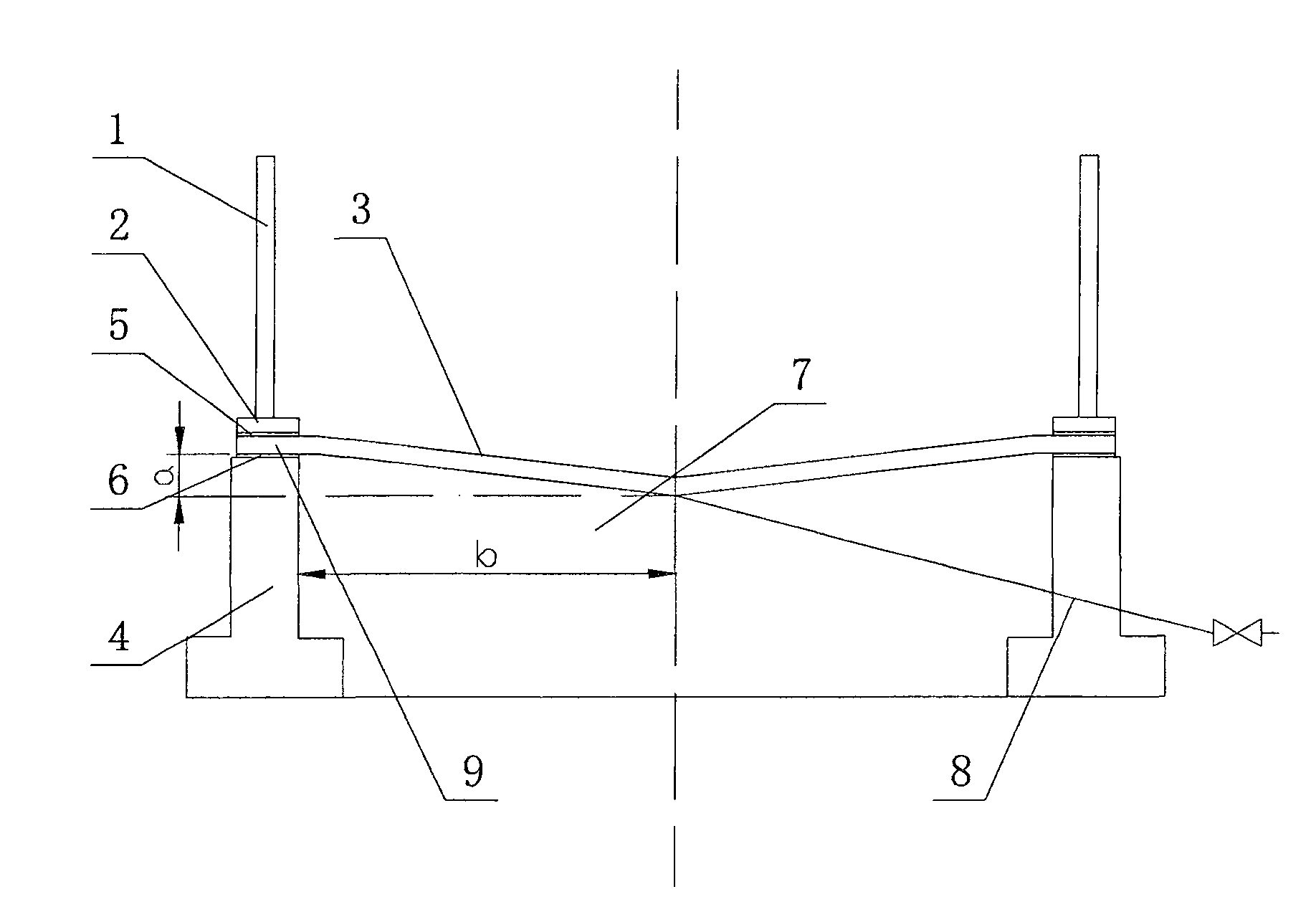

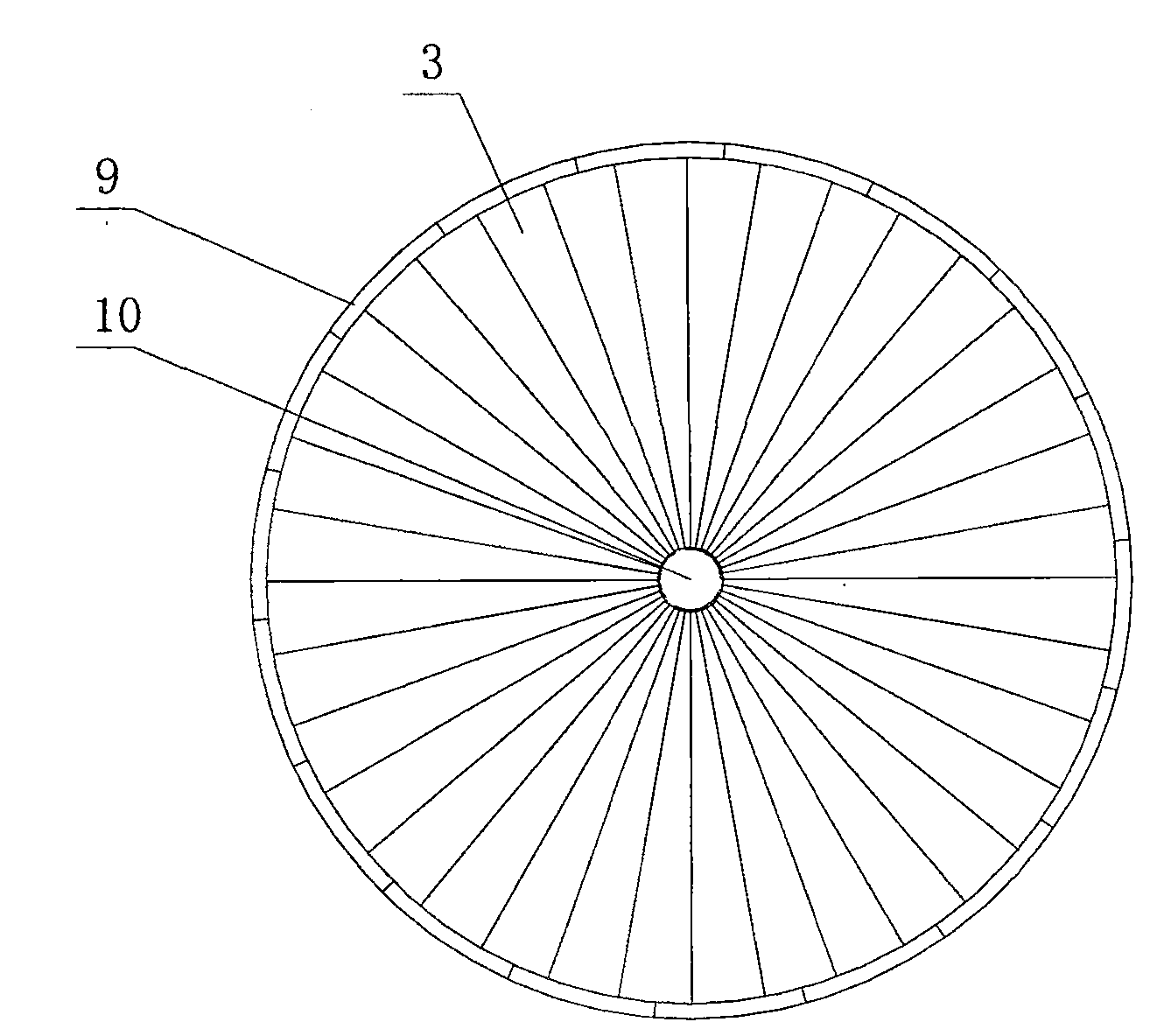

[0010] Depend on figure 1 As shown, a conical bottom plate of a composite rubber vertical storage tank includes a steel plate edge plate 2, and the steel plate edge plate 2 is a steel plate, which ensures the structural rigidity of the vertical storage tank and is also beneficial to the lift-off effect of the floating tank. It is not easy to damage the elephant feet caused by earthquakes; the composite rubber bottom plate has strong corrosion resistance, the material cost and construction cost are greatly reduced compared with the steel bottom plate, and the construction process is simplified at the same time. The medium plate 3 is in an inverted conical shape, and the slope i=a / b=0.03~0.05, which solves the existing problems of difficult emptying and venting of storage tanks; improves the stress system of the bottom plate, and the vertical positive pressure Decomposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com