Controller capable of controlling thickness of steel hogging moment steel bar protecting layer of bar concrete cast-in-situ plate and thickness of bar concrete cast-in-situ plate

A technology of negative moment reinforcement and protective layer thickness, applied to structural elements, building components, building reinforcements, etc., can solve the problems of increased building load, reduced impermeability of reinforced concrete, and uneven thickness of reinforced protective layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

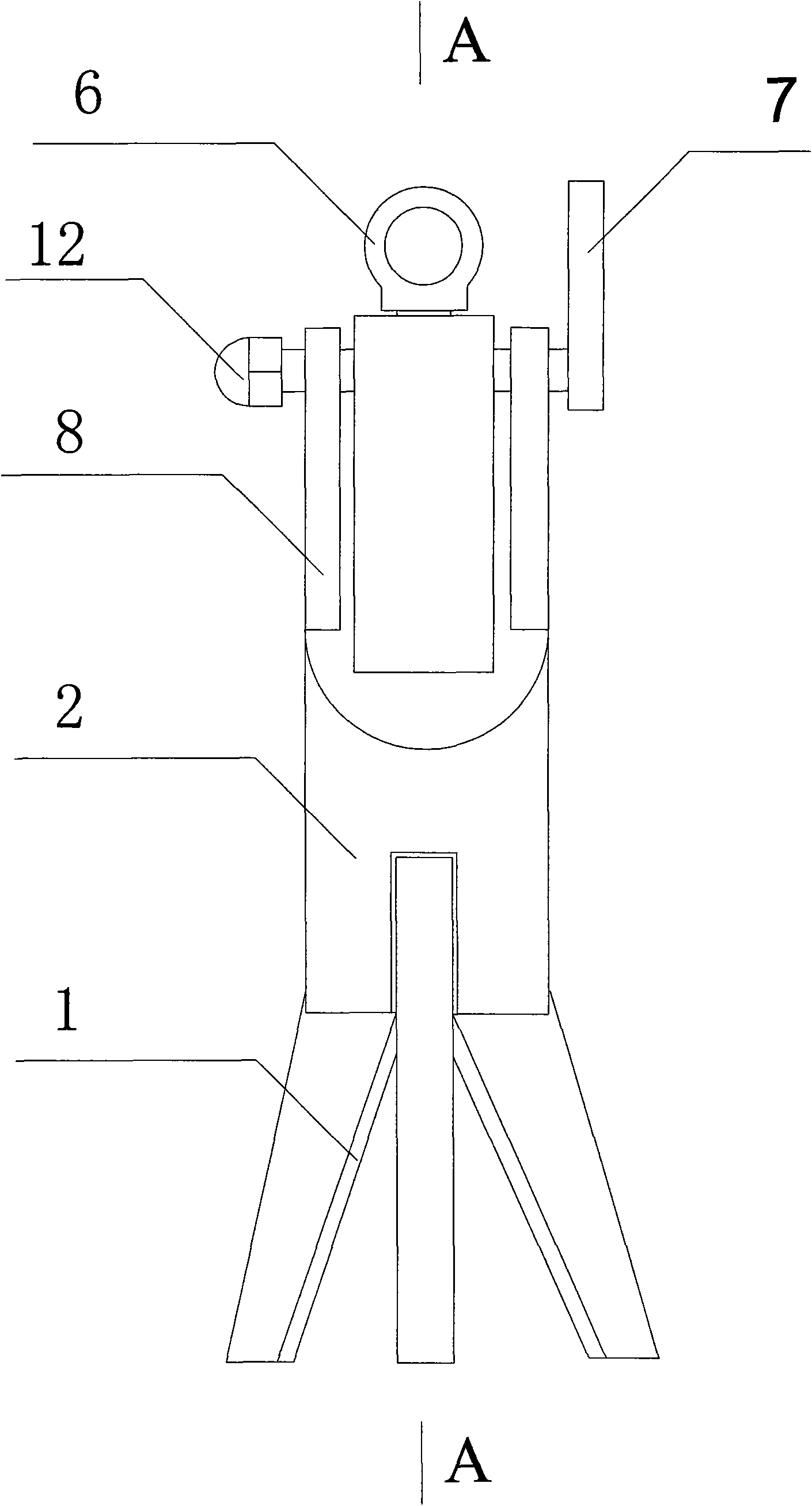

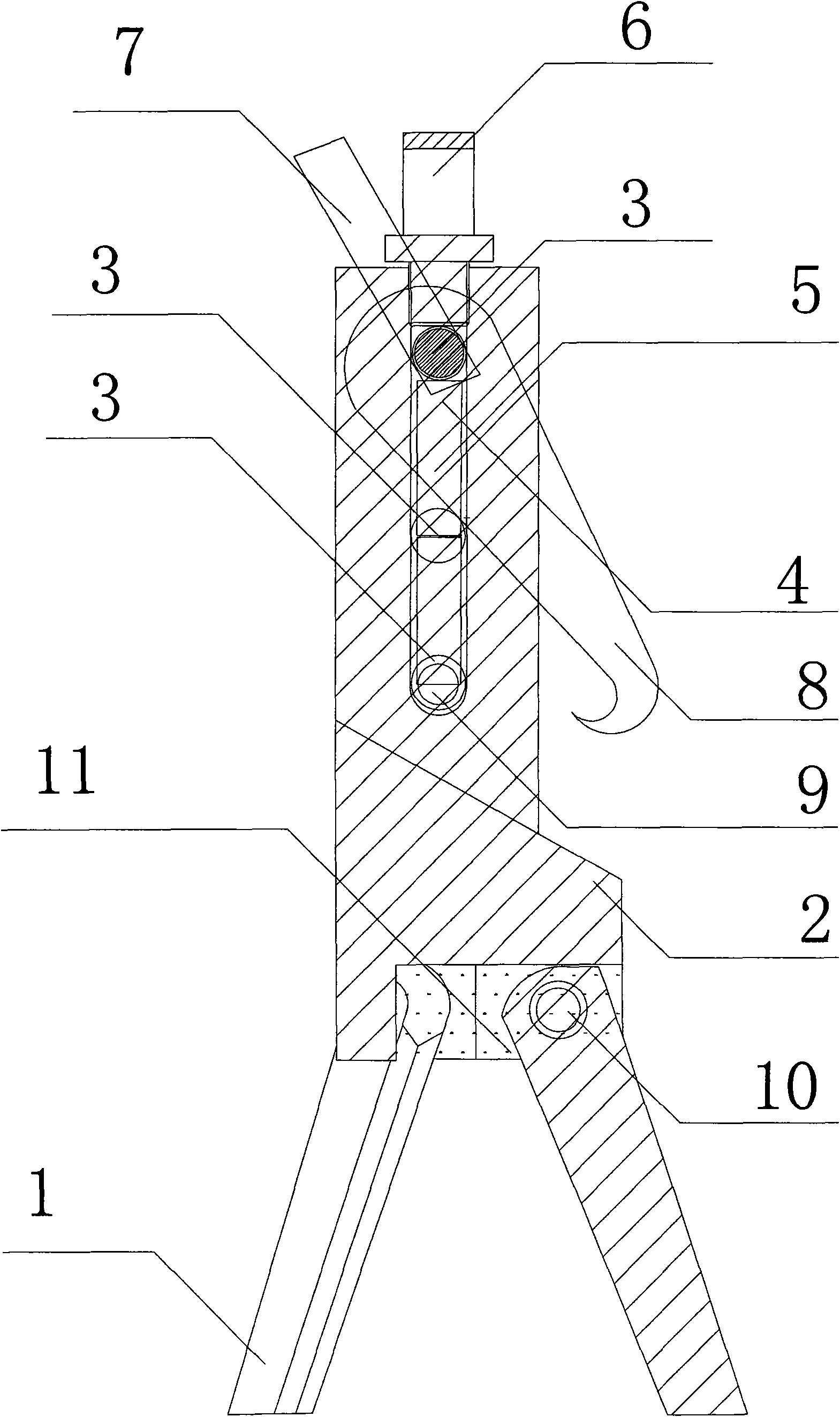

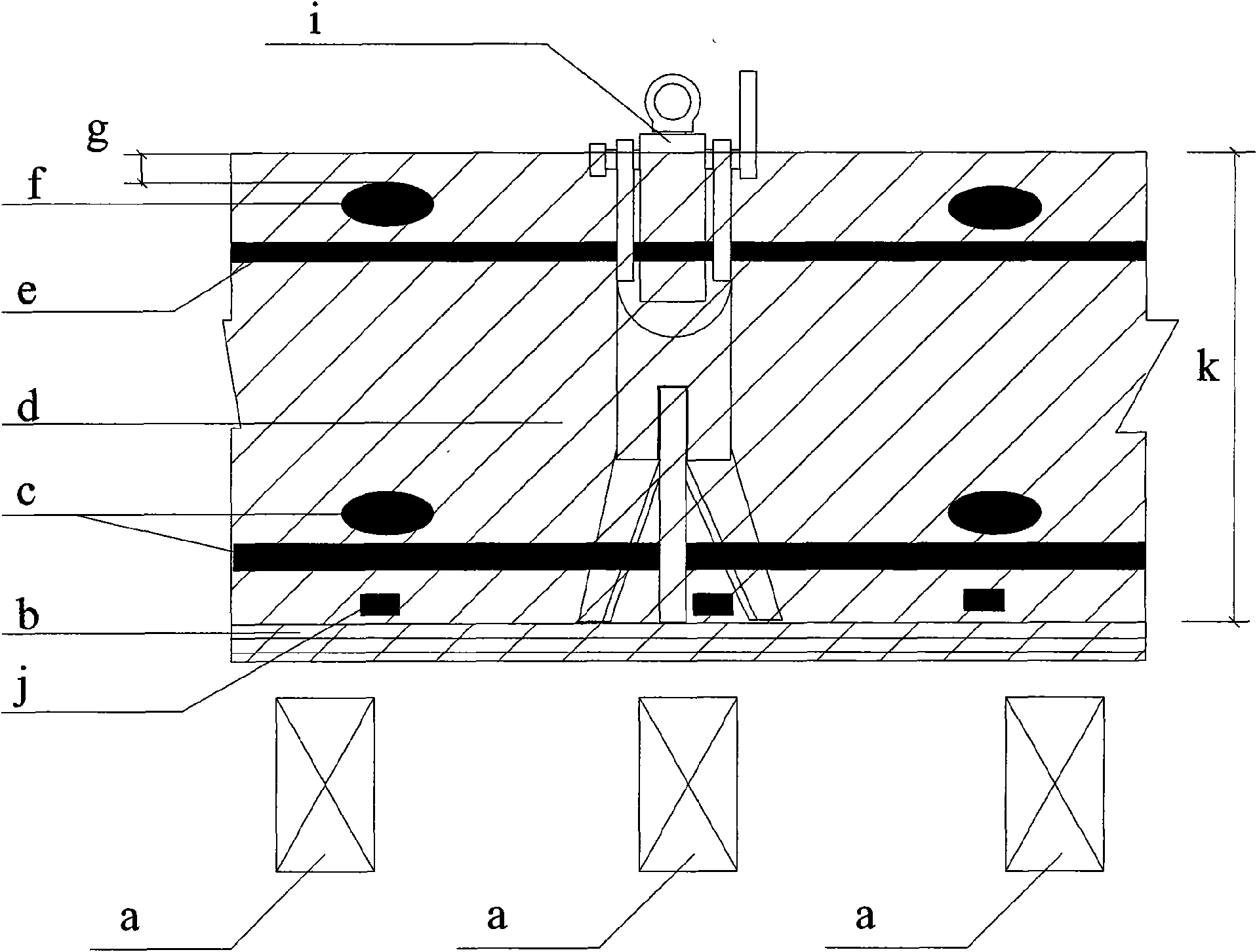

[0025] like Figure 1-2 As shown in the figure, the negative bending moment of the reinforced concrete cast-in-situ slab, the thickness of the steel protective layer and the thickness of the slab, it includes three three-way legs 1, and a column 2 connected to the leg 1; the lower part of the column 2 is a circular support, and the circular support The seat is hinged with the three-way support foot 1; the upper three sides of the column 2 are square and one side is circular, and the upper part of the column 2 is provided with three cast-in-place plate thickness control holes 3 and an internal thread locking control hole 4 that is perpendicular to the control hole 3; The inner thread locking control hole 4 is provided with two compensating rods 5, and the locking extraction bolt 6 is connected with the locking control hole 4 by wire; Ruler bolt 7, two negative bending moment steel bar locking claw rods 8 are linked with the cast-in-place slab thickness plate hand ruler marker 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com