Low-temperature concretion adhesive for cold press iron coke and preparation method thereof

A technology of binder and iron coke, applied in the field of iron and steel metallurgy to achieve the effect of increasing the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

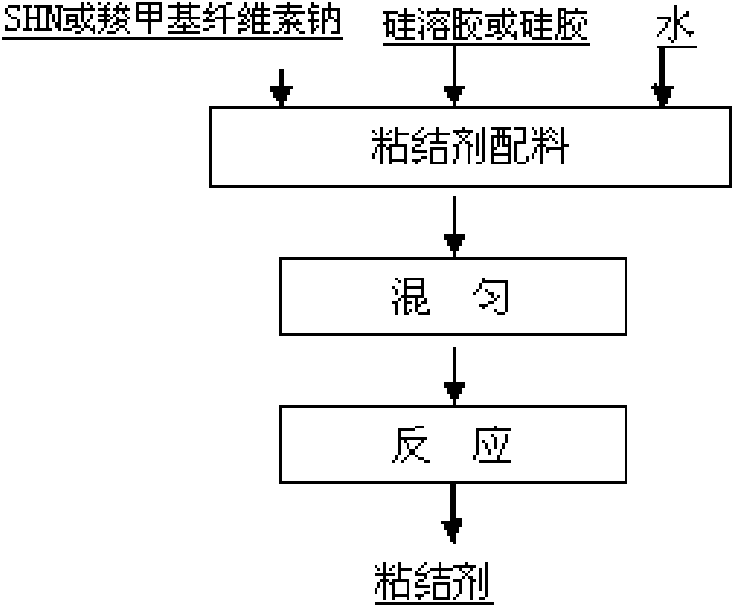

Method used

Image

Examples

Embodiment 1

[0028] Example 1: The ratio of raw materials for producing a binder SHN: silica sol: water is 1:5:12, 0.2% NaOH is added as a stabilizer, and the mass percentage of silica sol is 40.0%. The reaction conditions are as follows: the reaction temperature of the reactor is 180° C., the vapor pressure is 1.3 Mpa, and the reaction time is 2.5 hours. The binder is obtained by cooling and separating the sedimented insoluble matter.

Embodiment 2

[0029] Example 2: The raw material ratio of SHN: silica gel: water for the production of adhesive is 1:5:12, 0.3% KOH is added as a stabilizer, and the mass percentage of silica gel is 50.5%. The reaction conditions are as follows: the reaction temperature of the reactor is 185°C, the vapor pressure is 1.2Mpa, the reaction time is 3 hours, and the insoluble matter is cooled and separated to obtain the binder.

Embodiment 3

[0030] Embodiment 3: The ratio of raw materials for producing the binder is sodium carboxymethyl cellulose: silica sol: water is 1.2: 6: 12, 0.2% NaOH is added as a stabilizer, and the mass percentage of silica sol is 40%. The reaction conditions are as follows: the reaction temperature of the reactor is 190°C, the vapor pressure is 1.2Mpa, the reaction time is 2.5 hours, the insoluble matter is cooled and separated to obtain the binder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com