Method for hydrotreatment of heavy fraction of pyrolysis gasoline

A technology of pyrolysis gasoline and hydrogenation treatment, which is applied in the direction of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of large differences and inability to reduce other impurities, so as to reduce the reaction temperature, reduce equipment investment and operating costs , Guarantee the effect of the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

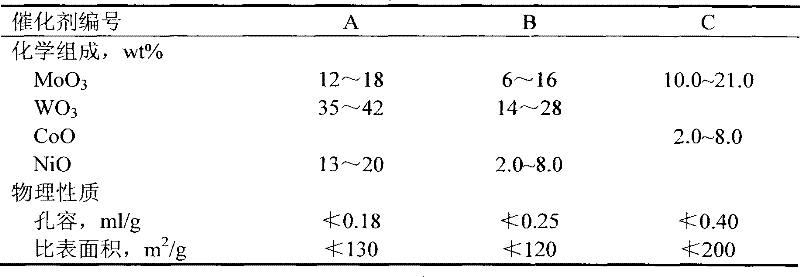

Image

Examples

Embodiment 1

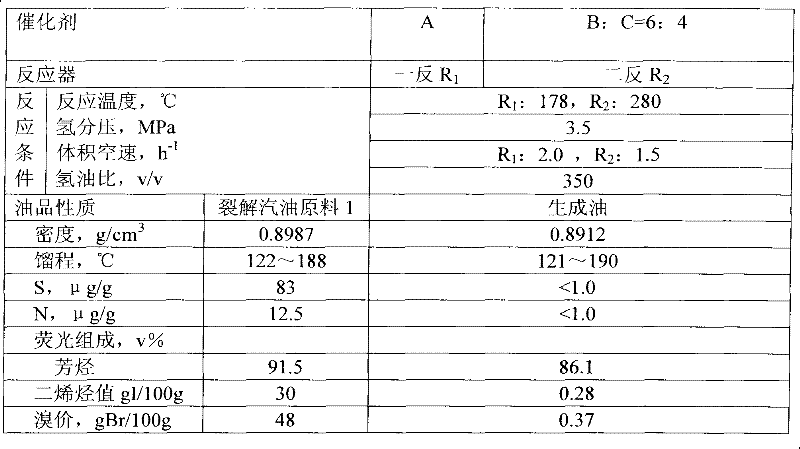

[0024] pyrolysis gasoline C 9 ~C 10Fraction 1 enters the first reactor after being contacted with hydrogen, and the reaction conditions are: hydrogen partial pressure 3.5MPa, volume space velocity 2.0h -1 , The reaction temperature is 178°C, and then directly enters the second reactor. The reaction conditions are: hydrogen partial pressure 3.5MPa, volume space velocity 1.5h -1 , The reaction temperature is 280°C. The total hydrogen to oil volume ratio is 350:1. The properties of raw oil and test results are listed in Table 2.

[0025] It can be seen from Table 2 that this technology can effectively remove heteroatoms such as sulfur and nitrogen, and the product can meet the index requirements.

[0026] Table 2 Raw oil properties and test results

[0027]

Embodiment 2

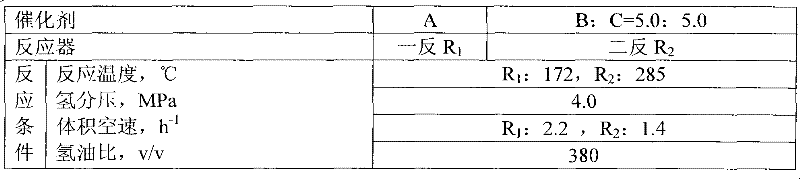

[0029] pyrolysis gasoline C 9 ~C 10 Fraction 2 enters the first reactor after being contacted with hydrogen, and the reaction conditions are: hydrogen partial pressure 4.0MPa, volume space velocity 2.2h -1 , The reaction temperature is 172°C, and then directly enters the second reactor. The reaction conditions are: hydrogen partial pressure 4.0MPa, volume space velocity 1.4h -1 , The reaction temperature is 285°C. The total hydrogen to oil volume ratio is 380:1. The properties of raw oil and test results are listed in Table 3.

[0030] It can be seen from Table 3 that this technology can effectively remove heteroatoms such as sulfur and nitrogen, and the product can meet the index requirements.

[0031] Table 3 Raw oil properties and test results

[0032]

[0033]

Embodiment 3

[0035] pyrolysis gasoline C 9 ~C 10 Fraction 3 enters the first reactor after being contacted with hydrogen. The reaction conditions are: hydrogen partial pressure 3.6MPa, volume space velocity 2.5h -1 , The reaction temperature is 175°C, and then directly enters the second reactor. The reaction conditions are: hydrogen partial pressure 3.6MPa, volume space velocity 1.6h -1 , The reaction temperature is 278°C. The total hydrogen to oil volume ratio is 400:1. The properties of raw oil and test results are listed in Table 4.

[0036] It can be seen from Table 4 that this technology can effectively remove heteroatoms such as sulfur and nitrogen, and the product can meet the index requirements.

[0037] Table 4 Raw oil properties and test results

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com