Method for extracting sulfur in sulfur-contained slag by chlorohydrocarbon organic solvent

A technology of organic solvents and chlorinated hydrocarbons, applied in solid solvent extraction, chemical instruments and methods, inorganic chemistry, etc., to achieve good dissolution effect, easy operation and maintenance, and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

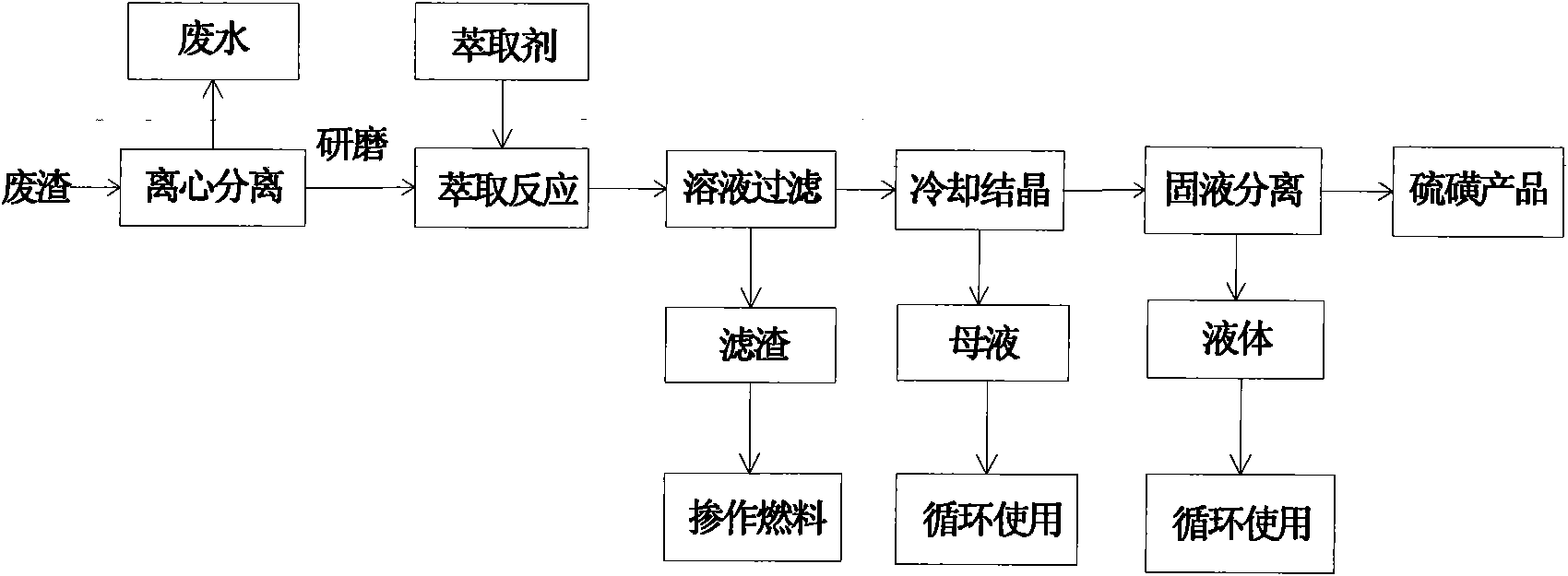

[0038] A method for extracting sulfur from sulfur-containing waste residue using chlorinated hydrocarbon organic solvents. It uses sulfur-bearing paste type sulfur-containing waste residue as raw material to obtain sulfur products through centrifugal separation, extraction reaction, solution filtration, cooling and crystallization, and solid-liquid separation. Proceed as follows:

[0039] (I) Select sulfur-containing waste residue for centrifugal separation, remove waste water, grind raw materials, and reserve;

[0040] (II) Metering the above-mentioned sulfur-containing grinding material into the extraction reactor;

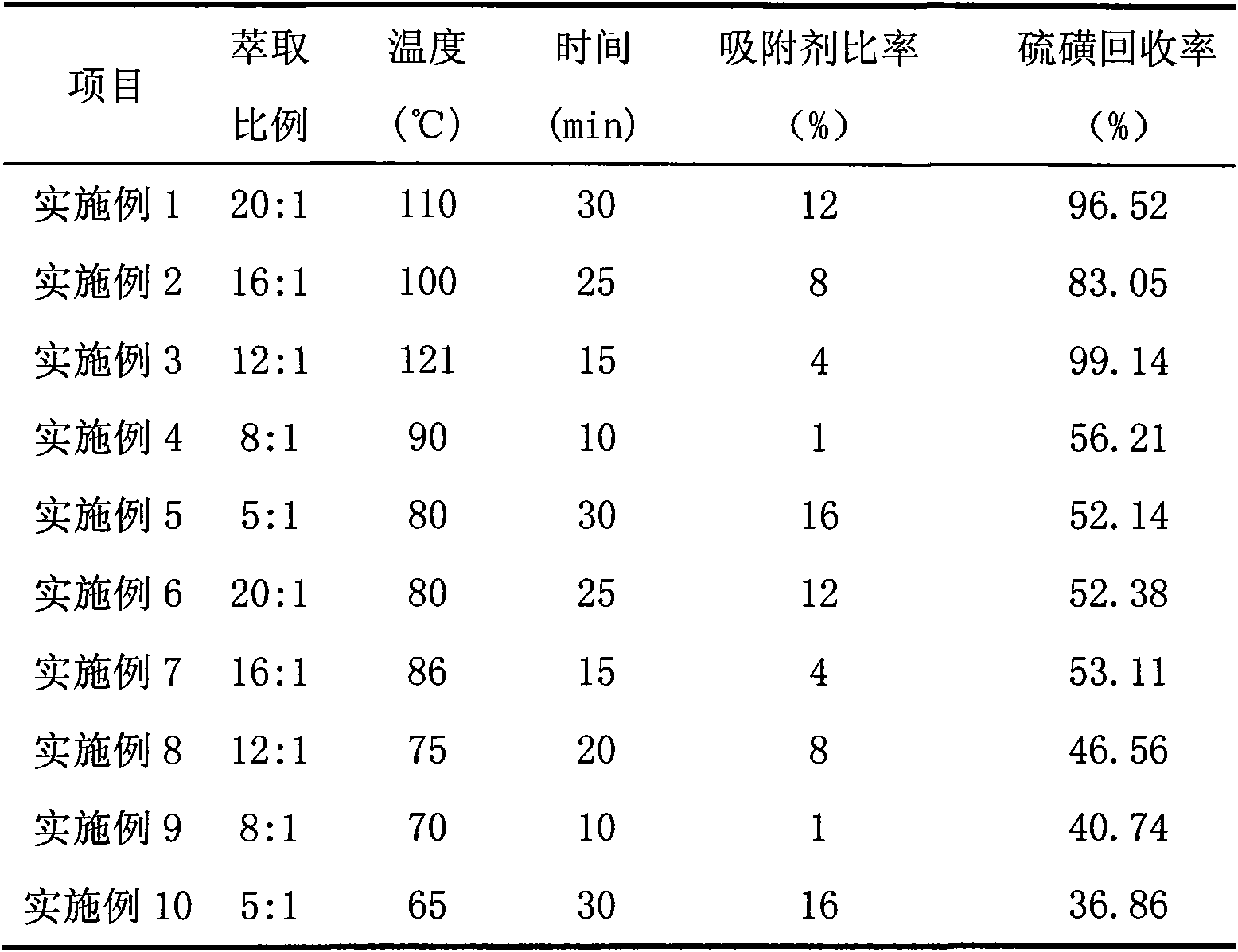

[0041] (III) Press solvent m again 1 : Sulfur-containing abrasive m 2 = 5~20:1 mass ratio adding solvent to boiling point 121.2℃, density 1.6226g / cm 3 Tetrachloroethylene or adding solvent has a boiling point of 86.7℃ and a density of 1.4649g / cm 3 At the same time, 1%-16% of the total mass of the sulfur-containing waste residue is added as an adsorbent for the extracti...

Embodiment 1

[0062] Put 54g of sulfur-containing grinding material into the reactor with a capacity of 1 liter. 1 : Sulfur-containing abrasive m 2 =20:1 mass ratio, the boiling point of the added solvent is 121.2℃, and the density is 1.6226g / cm 3 At the same time, add 6.48g of activated carbon with 12% of the total mass of sulfur-containing waste residue on a dry basis. Stir at 110°C and react for 30 minutes. The solution is insulated and filtered, cooled and crystallized, and solid-liquid separated. The net weight of sulfur product is 39.80g. According to the sulfur content in the dry basis, the sulfur recovery rate is 96.52%.

Embodiment 2

[0064] Put 54g of sulfur-containing grinding material into the reactor with a capacity of 1 liter. 1 : Sulfur-containing abrasive m 2 =16:1 mass ratio, the boiling point of the added solvent is 121.2℃, and the density is 1.6226g / cm 3 At the same time, add 4.32g of activated carbon with 8% of the total mass of sulfur-containing waste residue on a dry basis. Stir at 100°C and react for 25min. The solution is heated and filtered, cooled and crystallized, and solid-liquid separated. The net weight of sulfur product is 34.25g. According to the sulfur content in the dry basis, the sulfur recovery rate is 83.05%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com