Ship hatchcover opening device

A technology for opening devices and hatch covers, which is applied to ship hatches/hatches, fluid pressure actuating devices, ship parts, etc. Improved safety and vessel stability, reduced height, reduced footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

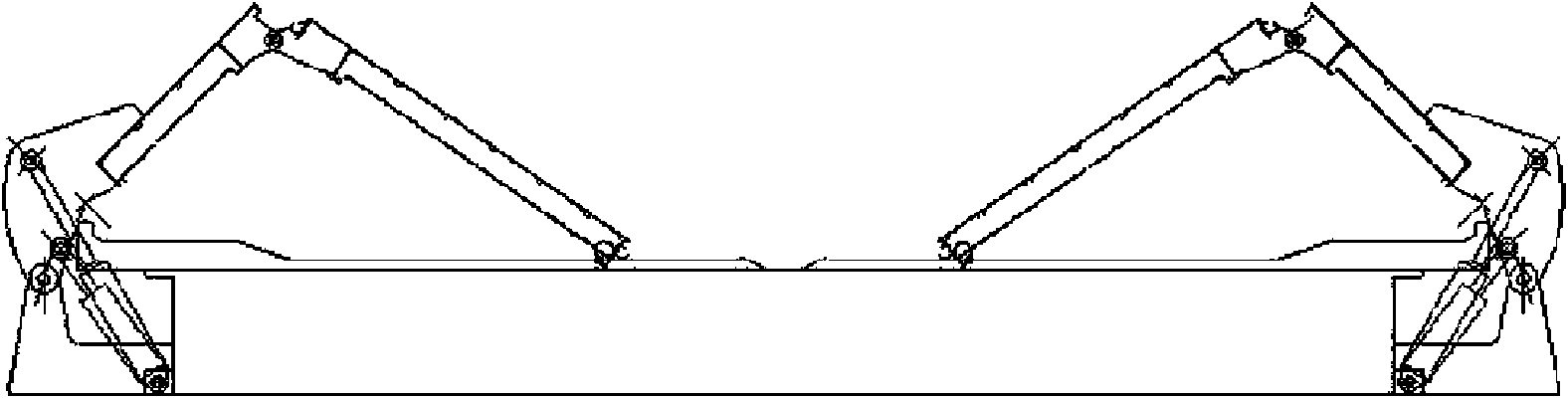

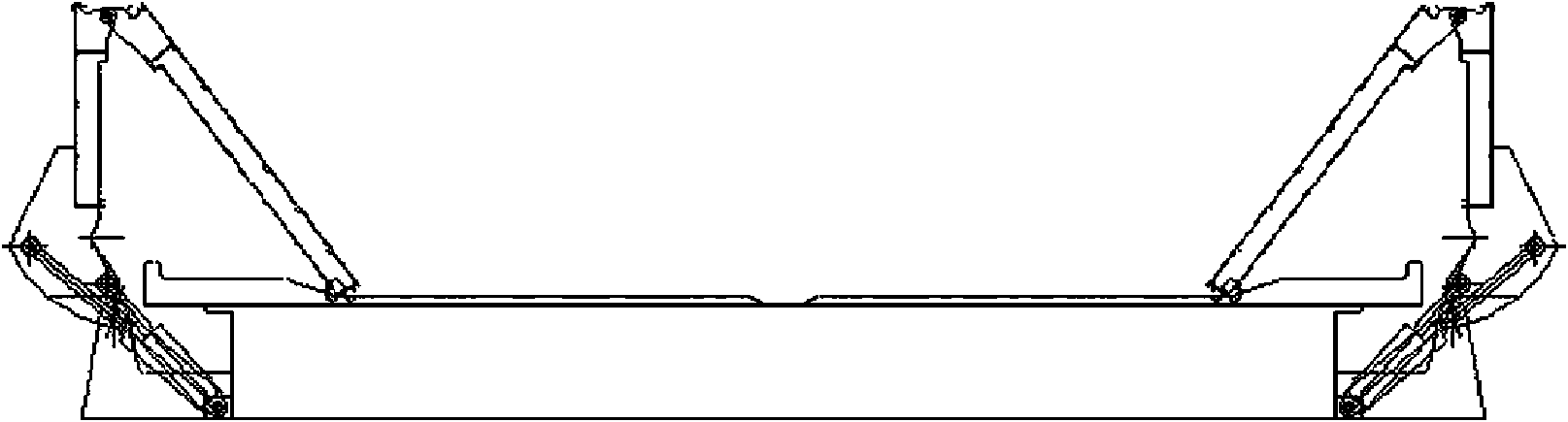

[0019] The ship hatch opening device of the present invention comprises an active hatch 5, a follower hatch 6 and a mounting seat 1 arranged on the side of the hatch, the mounting seat 1 is hinged with a flip cover 2, and the flip cover 2 and One side end of the active hatch 5 is fixedly connected to drive the active hatch 5 to turn outwards, the other side of the active hatch 5 is hinged with the rear end of the follower hatch 6, and the follower hatch 6 is hinged. The front end of the moving hatch 6 is provided with a hatch roller 7, and the periphery of the hatch is correspondingly provided with a roller motion guide rail 8, so that when the rear end of the follow-up hatch 6 turns over with the active hatch 5, The front end of the follower hatch 6 can slide along the roller motion guide rail 8; the first oil cylinder 4 and the second oil cylinder 3 supplied by the double oil cylinder hydraulic control device are connected between the mounting seat 1 and the flip cover 2, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com