Hammer drill

An electric hammer and tool holding technology, used in portable impact tools, drilling/drilling equipment, portable drilling rigs, etc., can solve the problems of piston cylinder wear, reduced service life, impact, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described based on the drawings.

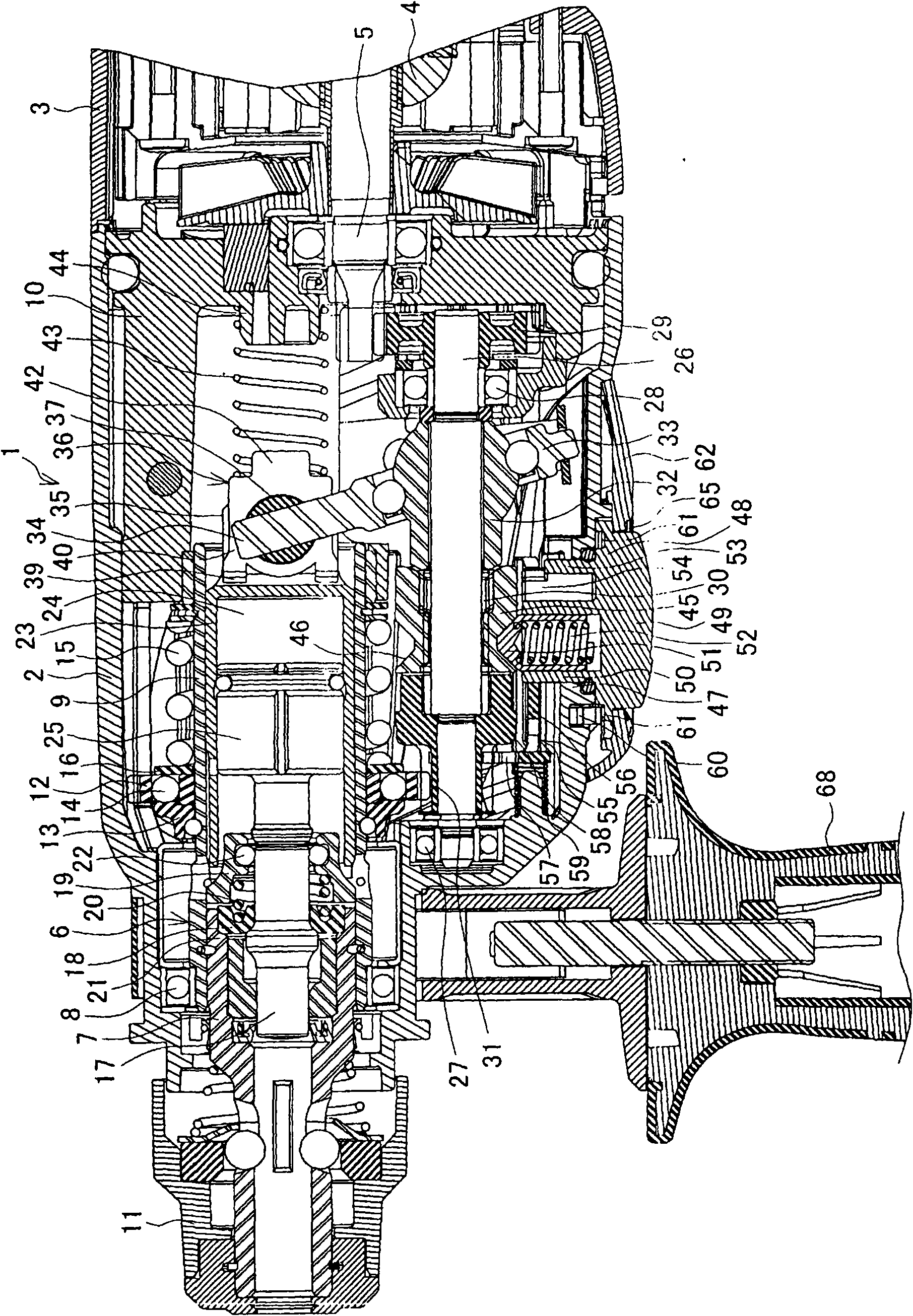

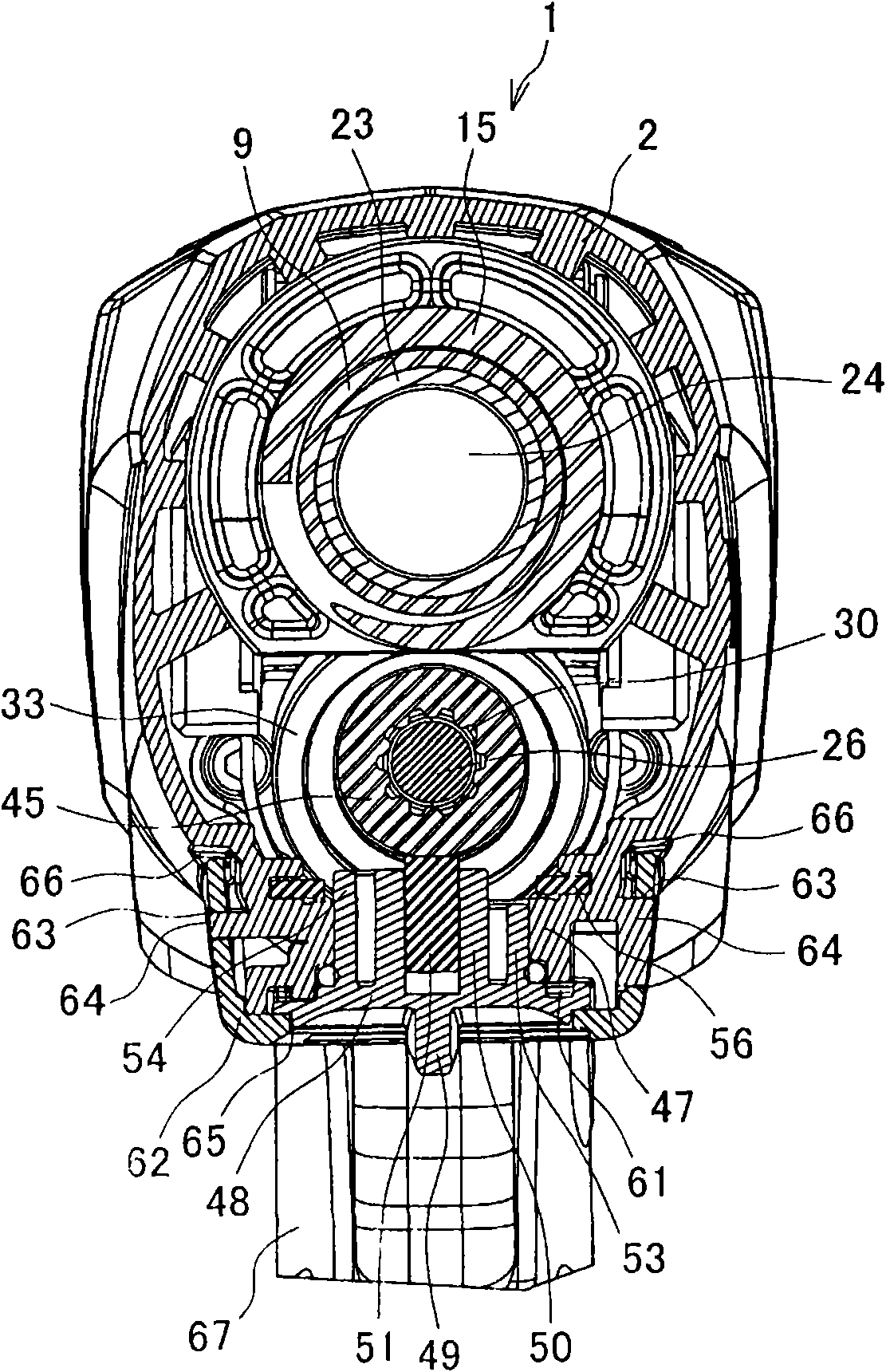

[0025] figure 1 Is a partial longitudinal sectional view showing an example of an electric hammer, figure 2 It is a cross-sectional view of its clutch part. The electric hammer 1 has: a gear box 2 with a rotation / impact mechanism inside; behind it ( figure 1 The right side of the middle) is used to house the motor housing 3 of the motor 4, and a tool holder 6 is supported on the front of the gear box 2. The tool holder 6 can rotate relative to the gear box 2, and its top end can be installed and processed head.

[0026] The tool holder 6 is a cylindrical body, the middle part 7 of which is supported by a ball bearing 8 at the front end of the gear case 2 and is rotatable relative to the gear case 2, and the large diameter part 9 at the rear is assembled in the rear of the gear case 2 The housing 10 is supported and rotatable relative to the internal housing 10, and an oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com