Method for manufacturing biomedical glass ceramic material

A technology of glass ceramics and manufacturing methods, applied in medical science, prostheses, etc., can solve the problems of lack of induction of bone growth, slow bone regeneration, insufficient mechanical strength, etc., and achieve the effect of shortening recovery time and accelerating tissue repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Because the manufacturing method of the biomedical glass-ceramic material provided by the present invention can be widely used in the production of biomedical glass-ceramic materials for various biomedical purposes, and the biomedical glass-ceramic material can be used as a bone substitute to induce bone Rapid growth and repair, and its combined implementations are too numerous to enumerate, so I won’t go into details one by one here, but only enumerate the preferred embodiments for specific illustrations, and cite the relevant experimental results to verify the aforementioned effects.

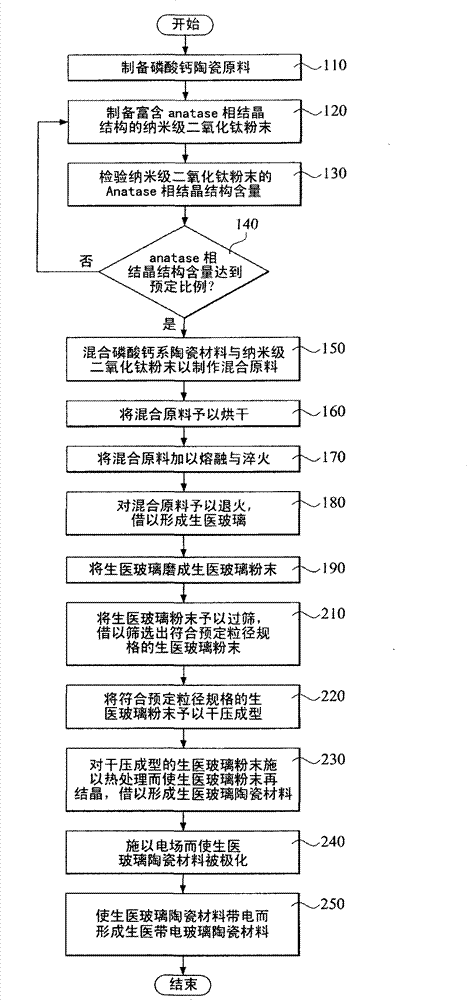

[0035] see figure 1 , which shows a flowchart of a preferred embodiment of the present invention. As shown in the figure, when realizing the present invention, calcium phosphate raw materials must be prepared earlier. Preferably, the calcium phosphate raw materials are composed of calcium oxide (CaO), dry phosphoric acid (P 2 o 5 ) and phosphoric acid (H 3 PO 4 ) is mixed and modula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com