Propagation of impact-induced cracks in brittle materials

A technology of brittle and brittle sheets, which is applied in the field of separation of brittle sheets, can solve problems such as high residual stress, thermal cracks, and slow separation, and achieve the effects of improving edge quality, reducing interference, and reducing glass particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

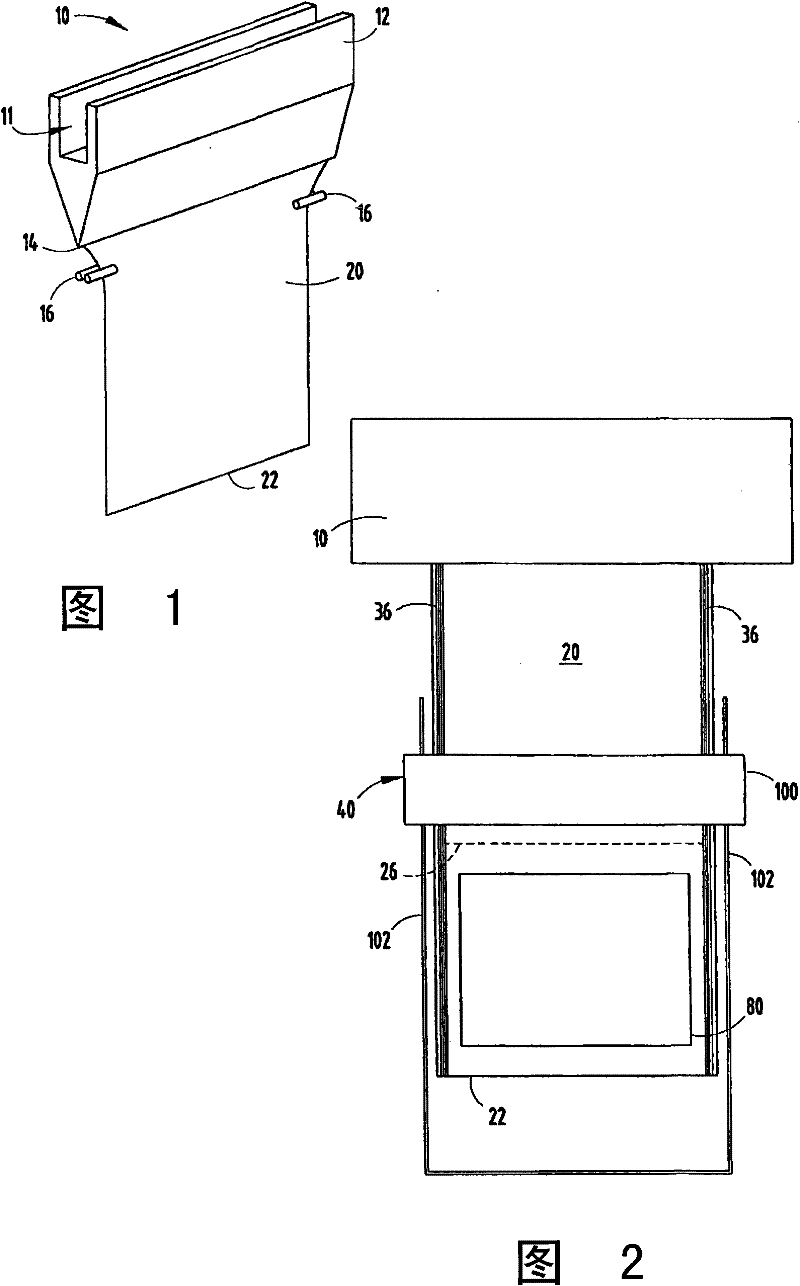

Image

Examples

Embodiment Construction

[0023] For the purpose of explanation and not limitation, the following detailed description provides exemplary embodiments revealing specific details in order to thoroughly understand the present invention. However, for those of ordinary skill in the art who understand the beneficial effects of the present invention, it is obvious that the present invention can be implemented in other embodiments different from the specific details disclosed in this specification. In addition, descriptions of well-known devices, methods and materials will be omitted so as not to interfere with the description of the present invention.

[0024] The invention provides a method for impact-induced separation of brittle materials without bending the brittle materials. In addition, the present invention avoids the use of a single powerful blow to cause the crack to propagate. The present invention provides a method for controlling separation time and edge quality. In one mode, the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com