Method for preparing fluorine-containing epoxy resin by phase transfer catalyst

A phase transfer catalyst and fluorine-containing epoxy resin technology, applied in the field of polymer preparation, can solve the problems of large molecular weight distribution range, large solvent discharge, unstable parameters, etc., and achieve stable product parameters, less solvent discharge, and reduced Single consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

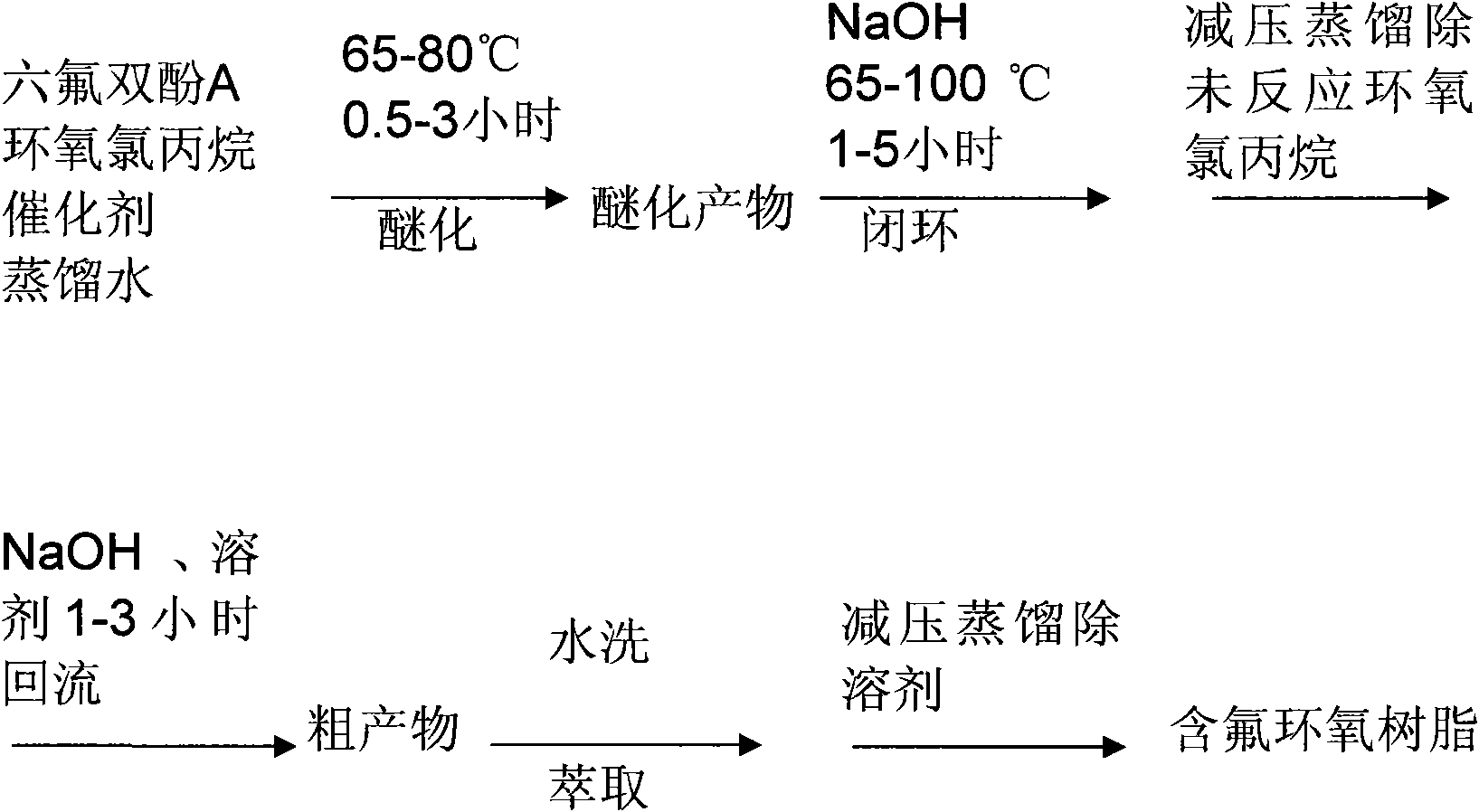

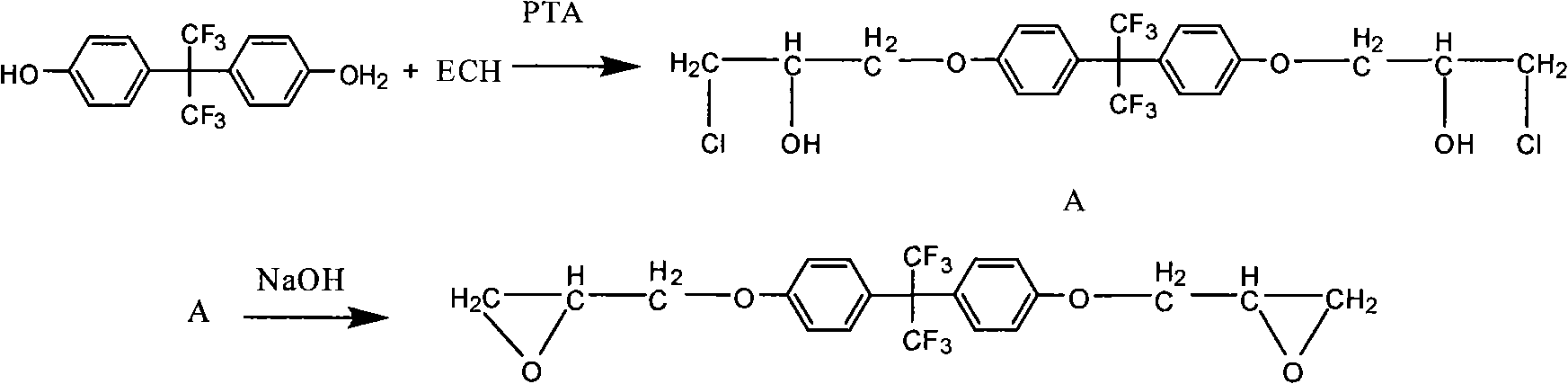

[0020] A kind of phase transfer catalyst prepares the method for fluorine-containing epoxy resin, such as figure 1 As shown, it includes the following steps:

[0021] 1) etherification reaction: choose 1mol of hexafluorobisphenol A (bisphenol AF), 10mol of newly steamed epichlorohydrin, 0.01mol of tetramethylammonium chloride, 10mol of distilled water; mix hexafluorobisphenol A, Add epichlorohydrin, tetramethylammonium chloride and distilled water into a four-necked bottle or reaction kettle equipped with a stirrer, a thermometer, a condenser and a dropping funnel, raise the temperature to 70°C, and react for 2 hours to obtain an etherification reaction liquid;

[0022] 2) ring-closing reaction: by the mole of the sodium hydroxide in the sodium hydroxide solution is 4mol, choose the sodium hydroxide solution that mass fraction is 20% (that is, contain 20g sodium hydroxide in the 100g sodium hydroxide solution); Choose the benzene of 3mol ; In the etherification reaction solu...

Embodiment 2

[0025] A kind of method that phase-transfer catalyst prepares fluorine-containing epoxy resin, it comprises the steps to carry out:

[0026] 1) etherification reaction: choose 1mol of hexafluorobisphenol A (bisphenol AF), 1mol of newly steamed epichlorohydrin, 0.005mol of tetraethylammonium chloride, 10mol of distilled water; mix hexafluorobisphenol A, Add epichlorohydrin, tetraethylammonium chloride and distilled water into a four-necked bottle or reactor equipped with a stirrer, a thermometer, a condenser and a dropping funnel, raise the temperature to 80°C, and react for 0.5 hours to obtain an etherification reaction liquid;

[0027] 2) ring-closing reaction: by the mole of the sodium hydroxide in the sodium hydroxide solution is 4mol, choose the sodium hydroxide solution that the mass fraction is 10%; Choose the toluene of 2mol; To the etherification reaction solution that step 1) obtains, add dropwise Sodium hydroxide solution with 50% of the total amount of sodium hydro...

Embodiment 3

[0030] A kind of method that phase-transfer catalyst prepares fluorine-containing epoxy resin, it comprises the steps to carry out:

[0031] 1) etherification reaction: choose 1mol of hexafluorobisphenol A (bisphenol AF), 1.4mol of newly steamed epichlorohydrin, 0.015mol of tetrabutylammonium chloride, 15mol of distilled water; , epichlorohydrin, tetrabutylammonium chloride and distilled water are added to a four-necked bottle or reactor equipped with a stirrer, thermometer, condenser and dropping funnel, heated to 65°C, and reacted for 2.5 hours to obtain etherification The reaction solution;

[0032] 2) ring-closing reaction: according to the mole of the potassium hydroxide in the potassium hydroxide solution is 5mol, choose the potassium hydroxide solution that mass fraction is 5%; Choose the xylene of 1mol; To step 1) drop in the etherification reaction liquid that obtains Add potassium hydroxide solution with 70% of the total amount of potassium hydroxide solution, react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com