Mo-V-Te-Nb-O catalyst, preparation method and application thereof

A catalyst, the technology of mo-v-te-nb-o, is used in the preparation of carboxylic acids by oxidation, chemical instruments and methods, catalysts for physical/chemical processes, etc. It can solve the problems of low propane reaction activity and achieve high catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

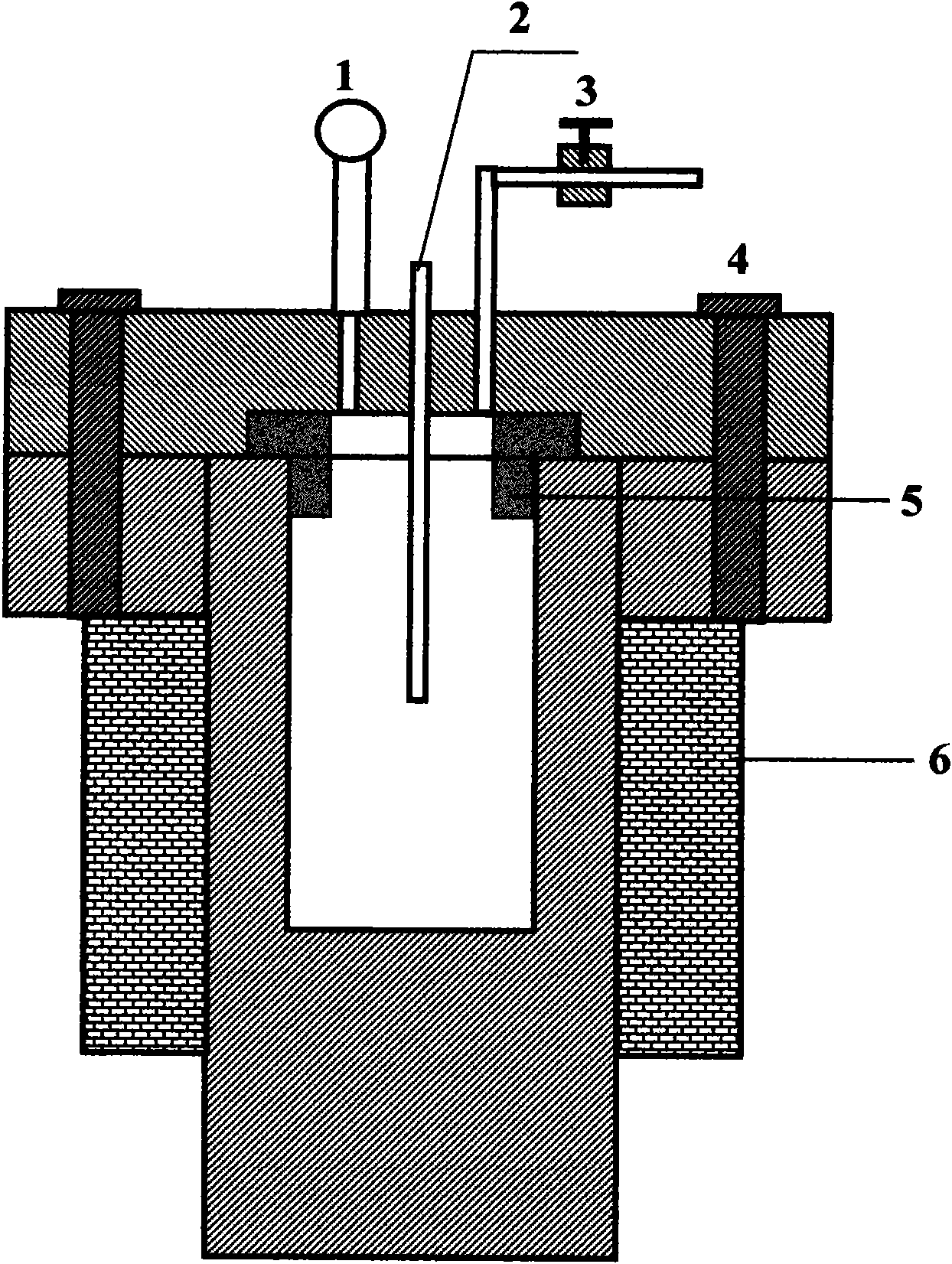

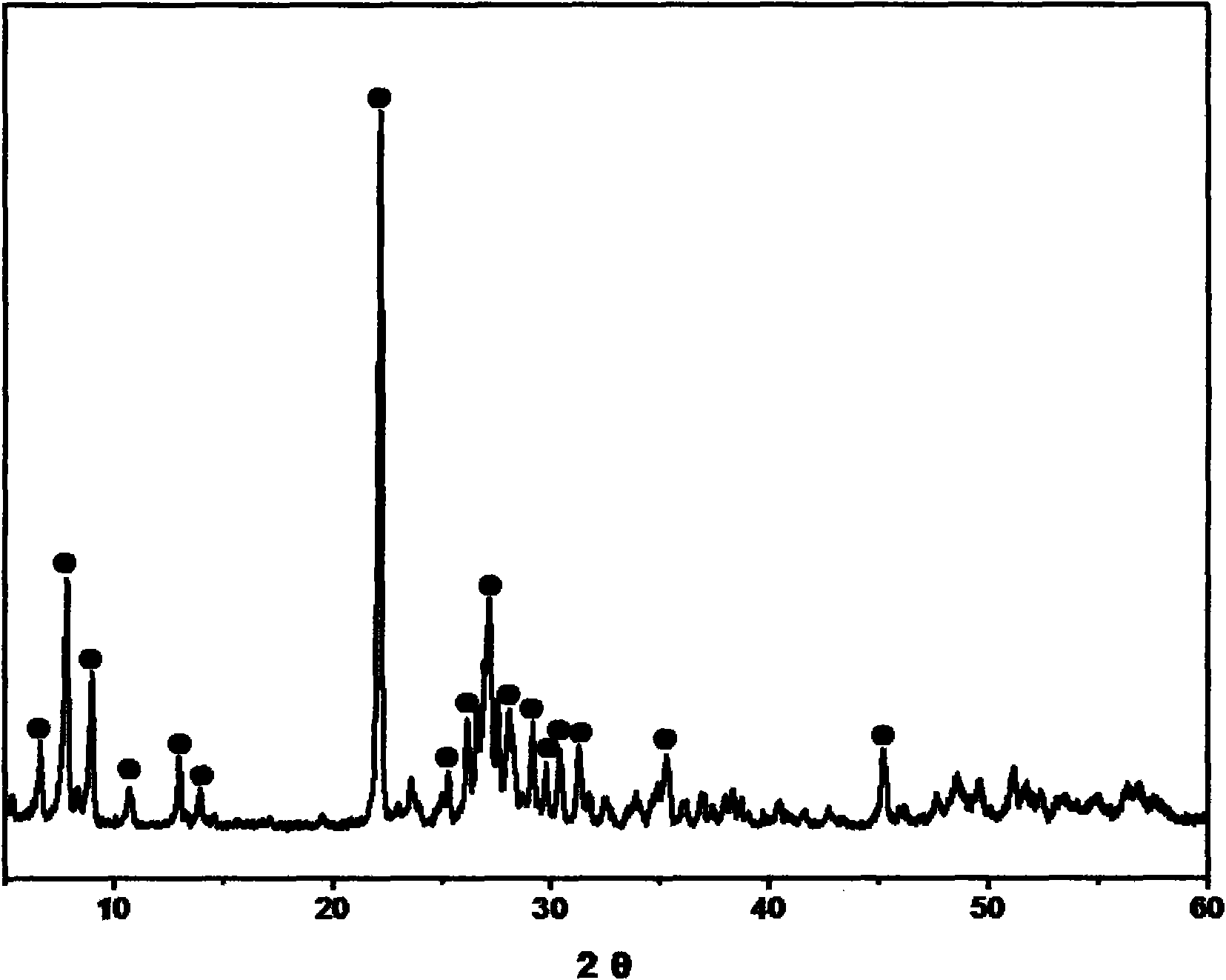

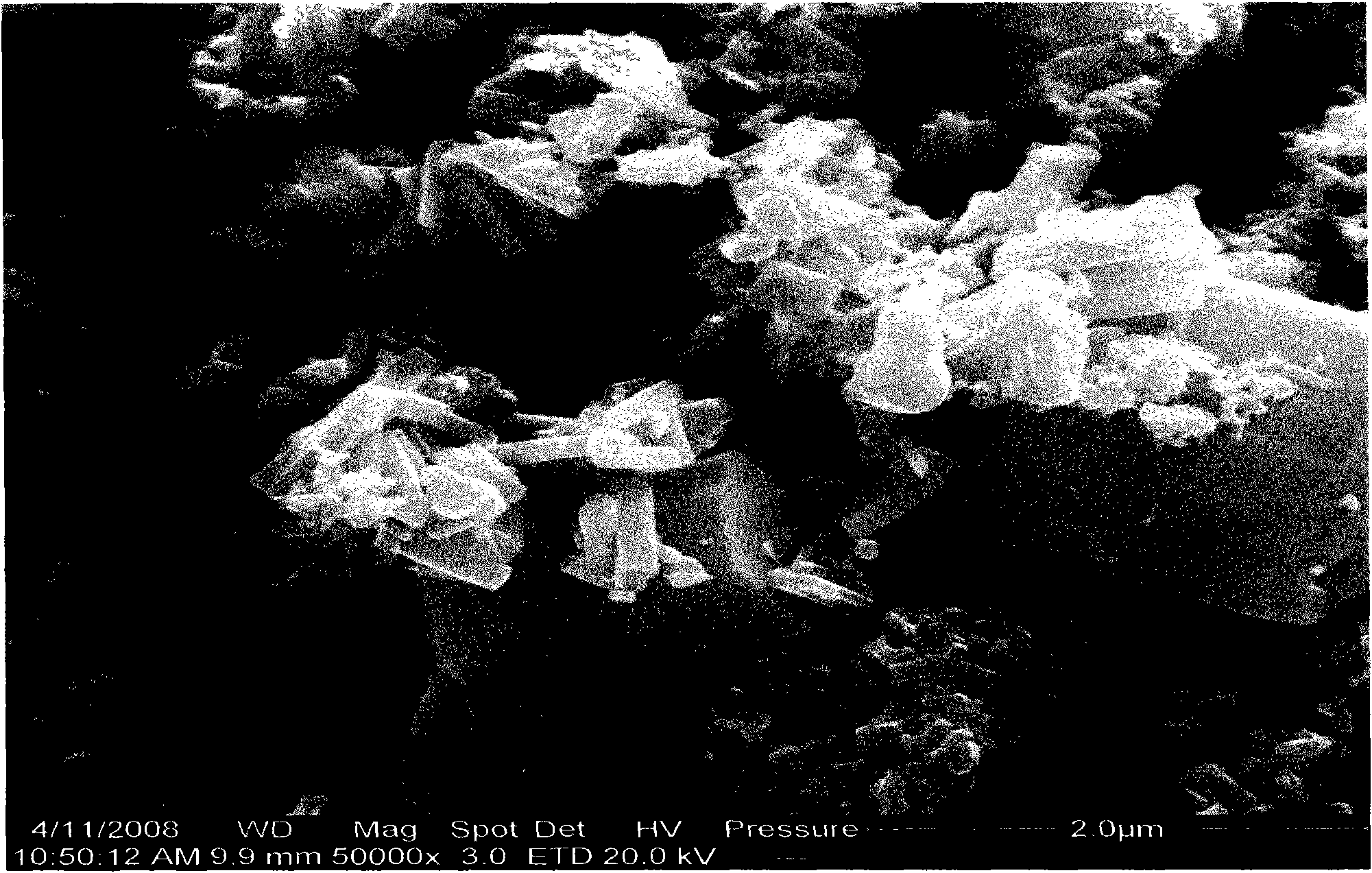

[0023] The Mo-V-Te-Nb-O catalyst was prepared by the temperature-programmed hydrothermal synthesis method, and the stoichiometric ammonium molybdate, vanadyl sulfate, telluric acid and niobium oxalate were respectively dissolved in hot deionized water, heated and stirred for 30~ After 60 minutes, slowly and sequentially mix the solutions together, continue to stir for 30 to 60 minutes, then pour all the mixed solutions into a special stainless steel reaction kettle (such as figure 1 Shown), the temperature was programmed from room temperature to 190-200 °C at a rate of 2-10 °C / min, the holding time was 16-20 hours, and then naturally cooled to room temperature. Then take it out, filter, dry, bake at 500-700°C for 2-5 hours, and grind it into 20-40 meshes. The catalyst sample prepared by this hydrothermal synthesis method is carried out XRD powder diffraction method measurement, and the result is as follows figure 2 Shown; The scanning electron microscope photo of the catalys...

Embodiment 2

[0025] The Mo-V-Te-Nb-O catalyst prepared in Example 1 was used in the selective oxidation of propane to acrylic acid. Weigh about 2g of 20-40 mesh catalyst, the reaction raw material gas ratio V(C 3 h 8 ): V(air): V(vapor)=1:15:12, the reaction pressure is normal pressure, the reaction temperature is 360°C, and the reaction space velocity is 800L Kg -1 h -1 , reacted for 2 hours. The conversion of propane was 67.3%, the selectivity of acrylic acid was 60.1%, and the yield was 40.4%.

Embodiment 3

[0027] An effective catalyst preparation method, if it is to be practical, must first ensure that the activity of any catalyst prepared by this method is similar in the reaction. In order to investigate the reproducibility of the activity of the Mo-V-Te-Nb-O catalyst prepared by the temperature-programmed hydrothermal synthesis method, we selected any two batches of catalysts synthesized by the in-situ hydrothermal synthesis method. Under the same reaction conditions, their catalytic performance in the selective oxidation of propane to acrylic acid was tested respectively. The result of the reaction is as Figure 5 shown. It can be seen from the figure that whether it is the selectivity of acrylic acid or the conversion rate of propane, the results of the two repetitions are very similar. It is proved that the catalyst prepared by the temperature-programmed hydrothermal synthesis method has very good activity repeatability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com