Inorganic-fiber ultra-high temperature composite filter material

A technology of inorganic fiber and composite filtration, which is applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems that the felt surface is separated from the base cloth, is not easy to bend, and is not easy to clean dust, so as to overcome poor cohesion, high The effect of filtering wind speed and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An inorganic fiber ultra-high temperature composite filter material, the preparation method is as follows:

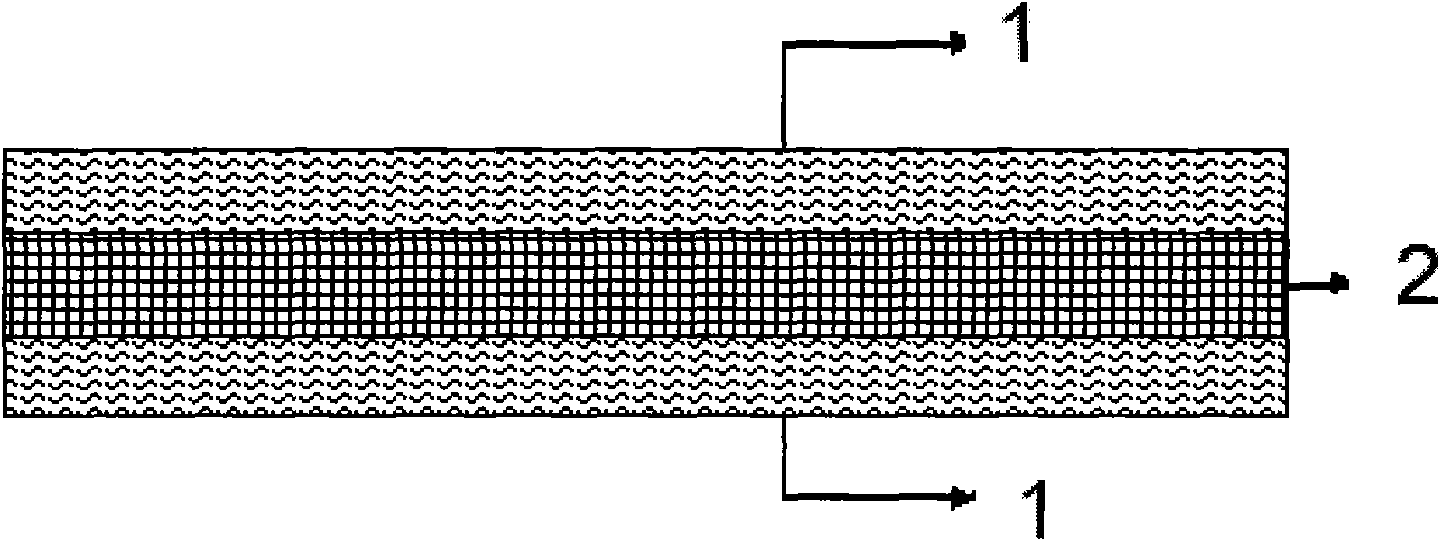

[0018] 1. Use basalt fiber filaments with a diameter of 7μ, interweave warp and weft yarns, and process them into 420g / m 2 Gram-weight base cloth layer 1. Blend stainless steel staple fibers with basalt fibers, the ratio is 10% of metal fibers, and form 150g / m after opening and carding 2 Stainless steel composite fiber felt layer 2.

[0019] 2. At a high temperature of 1500°C, the metal fibers are melted and welded on the warp and weft interweaving points of the base fabric by melting and sintering to form joints, thereby forming a uniform and compact ultra-high temperature basalt fiber composite felt.

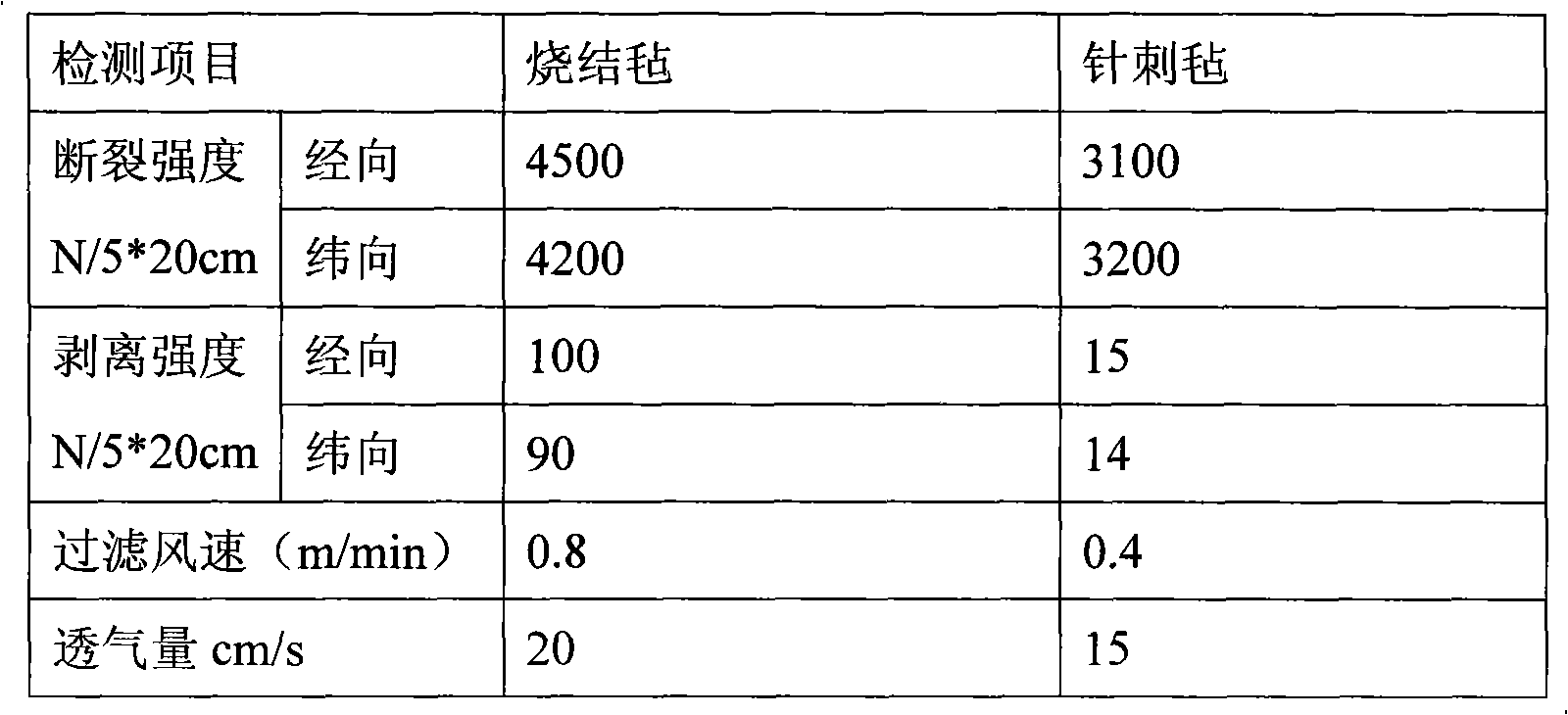

[0020] Performance comparison table 1

[0021]

[0022] As can be seen from Table 1, the product of the present invention has high breaking strength, and the peeling strength is more than 6 times that of common basalt needle felt. The anti-filtration wind ...

Embodiment 2

[0024] Another inorganic fiber ultra-high temperature composite filter material, the preparation method is as follows:

[0025] 1. Use ceramic fiber filaments with a diameter of 7μ, interweave warp and weft yarns, and process them into 560g / m 2 Gram-weight base cloth layer 1. The short stainless steel fiber and ceramic fiber are blended, the proportion is 30% of the metal fiber, after opening and carding, it is formed into 100g / m 2 The metal composite fiber felt layer, that is, the stainless steel composite fiber felt layer 2.

[0026] 2. At a high temperature of 1500°C, the metal fibers are melted and welded on the warp and weft interweaving points of the base fabric to form joints through the melting and sintering method, thereby forming a uniform and compact ultra-high temperature basalt fiber composite felt.

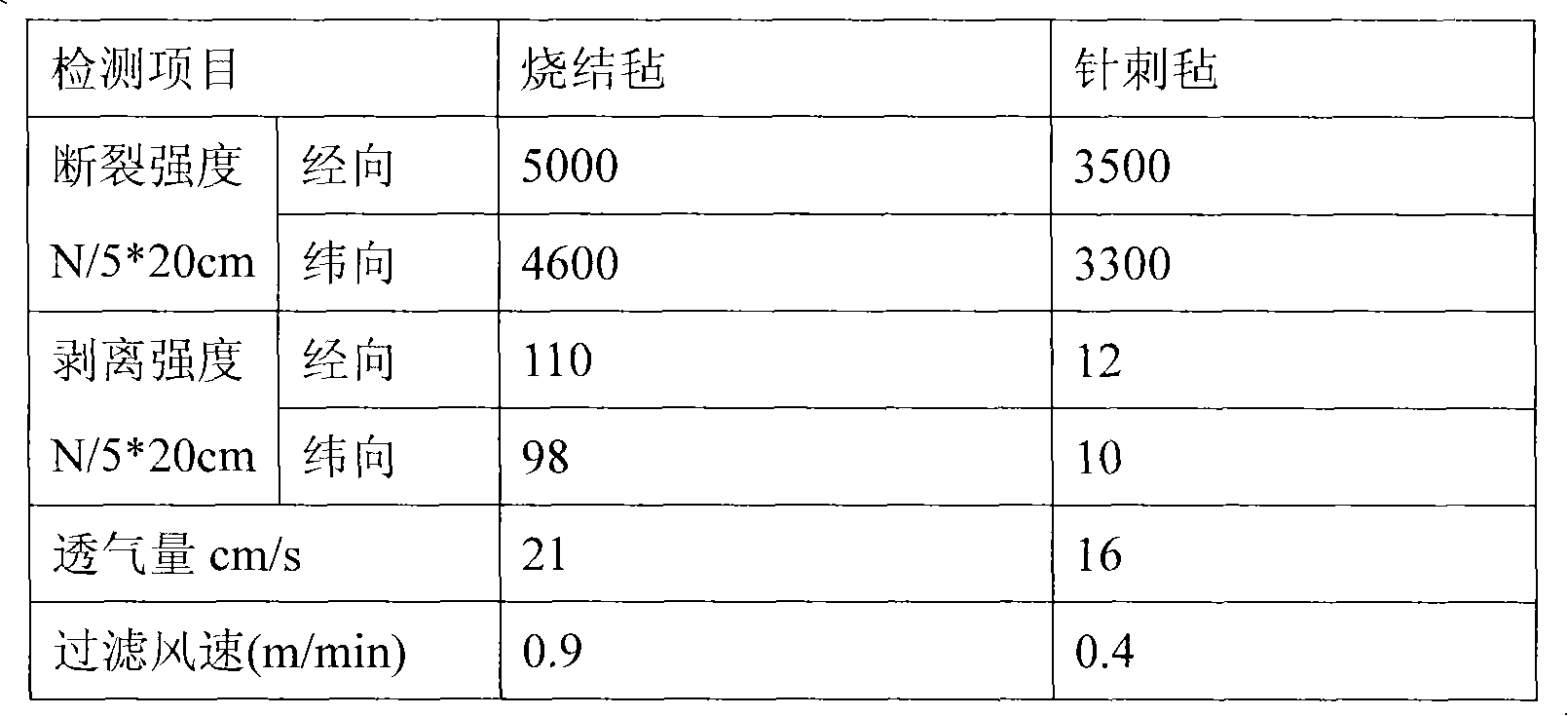

[0027] Performance comparison table 2

[0028]

[0029] As can be seen from Table 2, the product of the present invention has high breaking strength, and the p...

Embodiment 3

[0031] Another inorganic fiber ultra-high temperature composite filter material, the preparation method is as follows:

[0032] 1. Use short ceramic fibers with a diameter of 7μ, interweave warp and weft yarns, and process them into 330g / m 2 Gram-weight base cloth layer 1. The short stainless steel fiber and ceramic fiber are blended, the proportion is 20% of the metal fiber, after opening and carding, it is 250g / m 2 Stainless steel composite fiber felt layer 2.

[0033] 2. At a high temperature of 1500°C, the metal fibers are melted and welded on the warp and weft interweaving points of the base fabric to form joints through the melting and sintering method, thereby forming a uniform and compact ultra-high temperature basalt fiber composite felt.

[0034] Performance comparison table 3

[0035]

[0036] As can be seen from Table 3, the product of the present invention has high breaking strength, and the peeling strength is more than 9 times that of ordinary ceramic fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com