Full-area charged filtering dust remover

A technology for filtering dust collectors and dust collectors. It is applied in the fields of dispersed particle filtration, electrode cleaning, electrostatic separation, etc. It can solve the problems of low system resistance, low dust removal efficiency, and low operation and maintenance costs, and achieve low system resistance and high dust removal efficiency. , The effect of low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

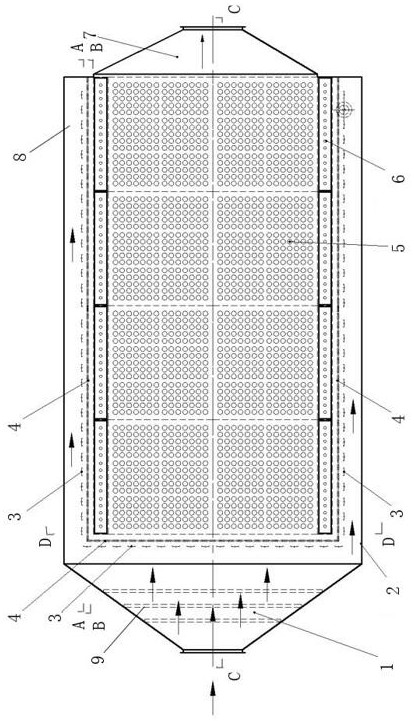

[0032] Such as Figure 1-Figure 8 As shown, the full-area charged filter dust collector includes a dust collector main box body 2, a pyramid-shaped air inlet 1 is provided on the front side of the dust collector main box body 2, and a bag filter is arranged inside the dust collector main box body 2. Dust removal area. The outer periphery of the bag filter and dust removal area is equipped with a front-entry wind charging assembly and a side-entry wind charging assembly. A side air inlet channel 8 is formed between the side walls of the body 2 . The front-entry wind charging assembly and the side-entry wind charging assembly respectively include a collector plate 4 for isolating the main box of the dust collector 2 from the dust removal area of the bag filter, and a discharge emitter net 3 corresponding to the collector plate 4 . Vent holes or vent gaps are evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com