Internal filtering dust filtering equipment

A technology of dust filtration and internal filtration, which is applied in the field of internal filtration dust filtration equipment, can solve the problems of high cost and inconvenient use, and achieve the effects of high automation, safe and reliable operation, and integrity maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

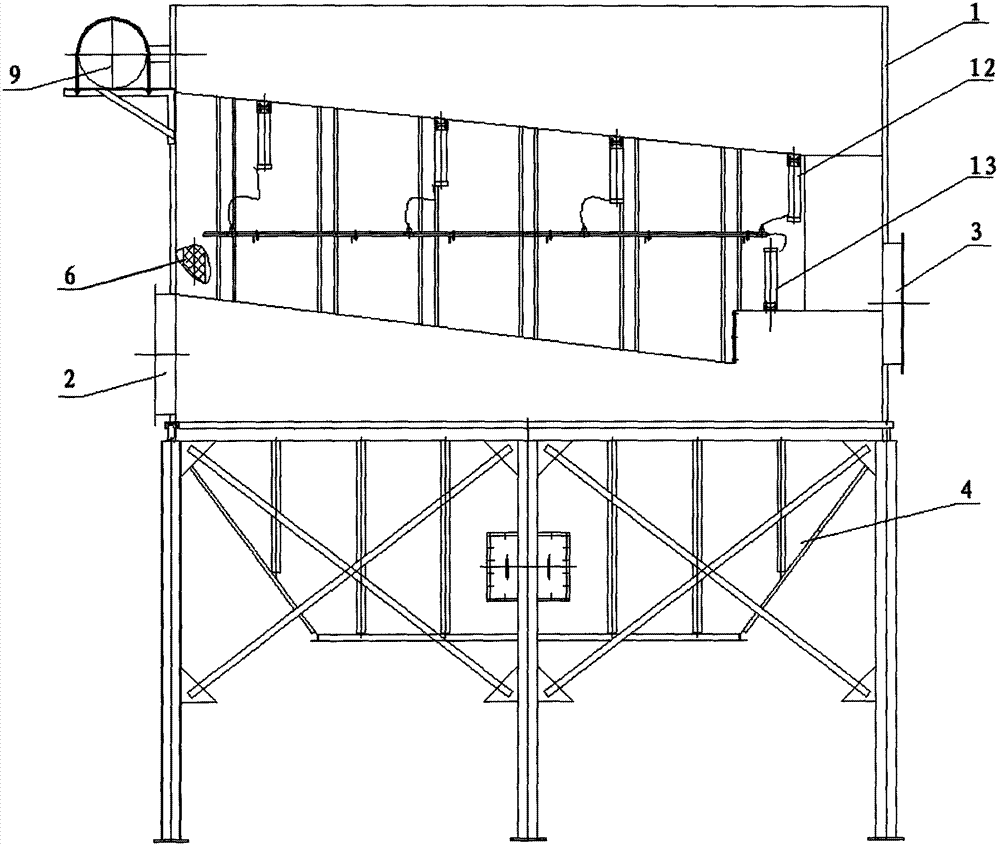

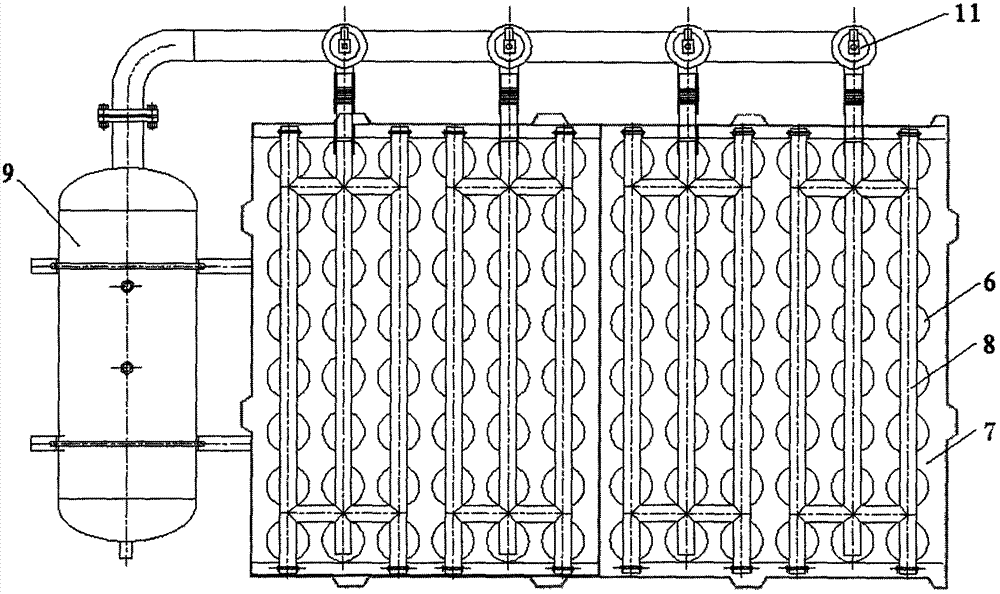

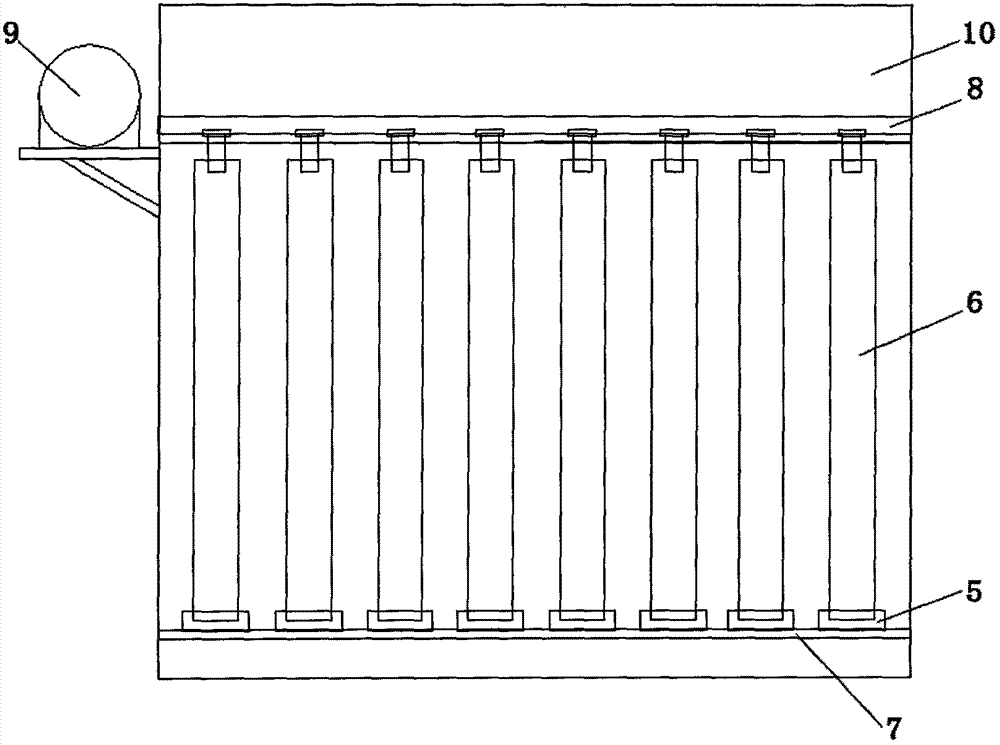

[0036] An embodiment of the present invention provides an inner filter type dust filter device, which is used to separate, capture and recycle particulate matter from dust-laden gas. The implementation process of the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

[0037] An inner filter type dust filter equipment, used to separate and recover particles from dusty gas through a filter, as attached figure 1 As shown, it includes: a box body 1 for support and protection; an air inlet 2 arranged on one side of the box body 1 and an air outlet 3 on the opposite side, which are respectively used for introducing dusty gas and discharging clean gas. The air inlet 2 controls the filtering wind speed below 1.4m / min. The ash storage box 4 is arranged under the box body 1 for receiving the dust collected by the dust collector, and a column is also arranged under the ash storage box 4 to play a supporting role.

[0038] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com