Production process of uv transfer printing molded key device

A production process and key technology, applied in the field of UV transfer ultra-thin key production technology, can solve problems such as difficulty in raw materials, and achieve the effects of simple operation steps, simple operation process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

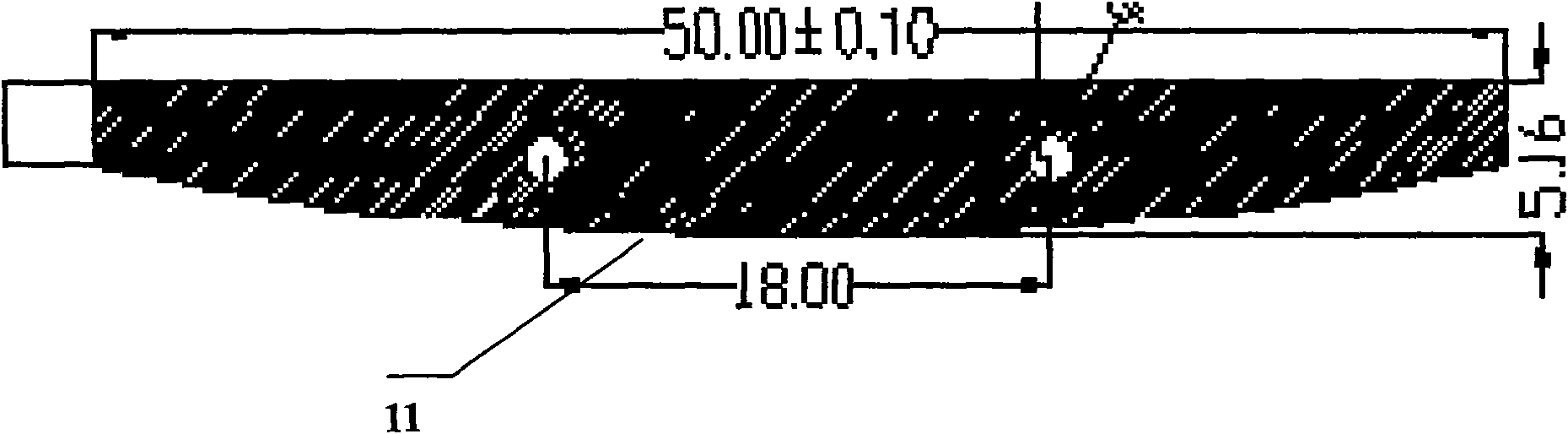

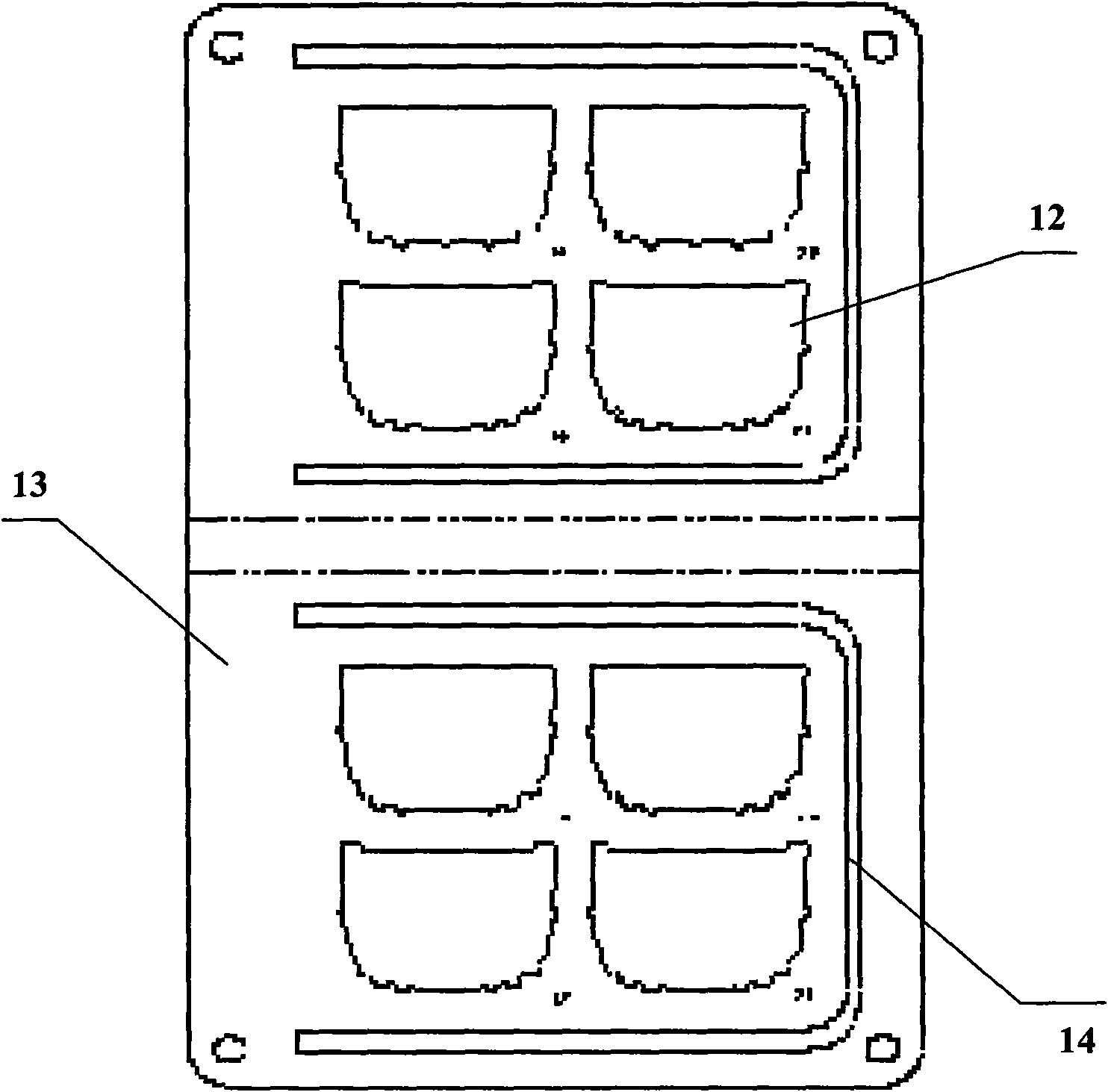

[0028] see figure 2 and Figure 4 The numerical value units marked in are all (mm).

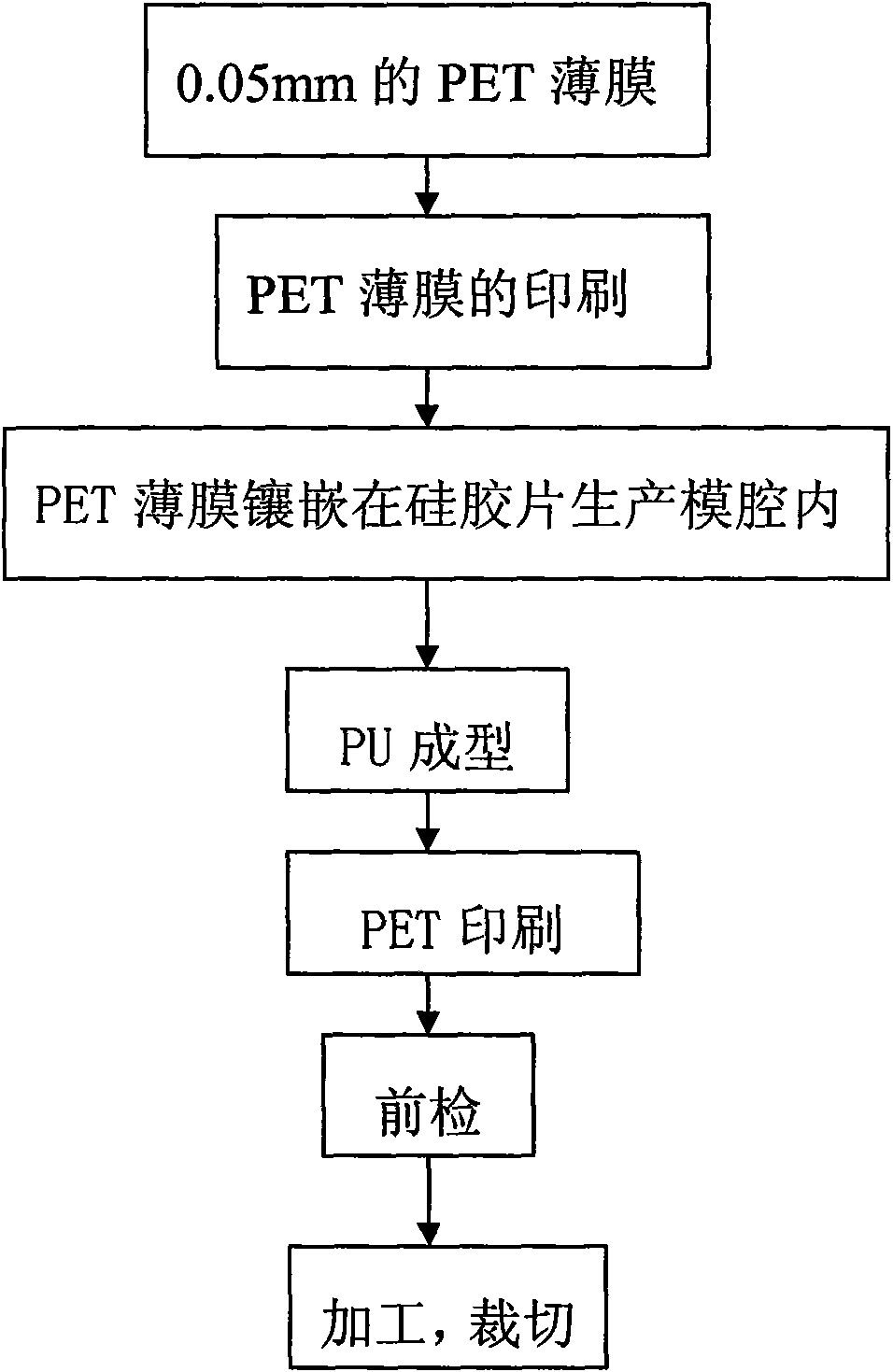

[0029] see figure 1 , the main steps of producing HF-0568 keys by using UV transfer printing forming key production process:

[0030] Pre-baking: pre-baking with infrared rays after loosening the whole roll of PC sheet, the pre-baking condition is 120°C / 8min; (Place the product printing surface) and then print varnish and add sulfur (120°C / 0.5H), then print adhesive, add sulfur (120°C / 1H); PU molding: dispense glue on the PU production mold, cover with PET film, Rolling, UV light curing machine (20±5S, temperature 55±5°C), demoulding; printing: the operation process is to discharge the product → discharge (put the product printing surface) → hollow words → add sulfur (60°C / 0.5 H)→black circle→add sulfur (60℃ / 0.5H)→cool gray 4C→pass IR line (45℃ / 90S)→021C (continuous printing 2 times)→pass IR line (45℃ / 90S)→transparent white Bottom → vulcanization (60°C / 0.5H); pre-inspection: check print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com