Duplex stainless steel with special magnetic property

A dual-phase stainless steel and magnetic performance technology, applied in the field of stainless steel materials, can solve the problems of high hardness of stainless steel and unsuitability for coinage, etc., achieve excellent corrosion resistance, ensure hot rolling yield, and good thermoformability

Inactive Publication Date: 2009-12-23

BAOSHAN IRON & STEEL CO LTD

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Since the material used for coinage requires low hardness and good plasticity, it should generally meet the requirements of hardness HV≤220 and elongation ≥20%. However, in the past, the alloy composition in duplex stainless steel was high, especially the high content of C and N, resulting in The hardness of stainless steel is too high, its hardness > 220, not suitable for coinage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

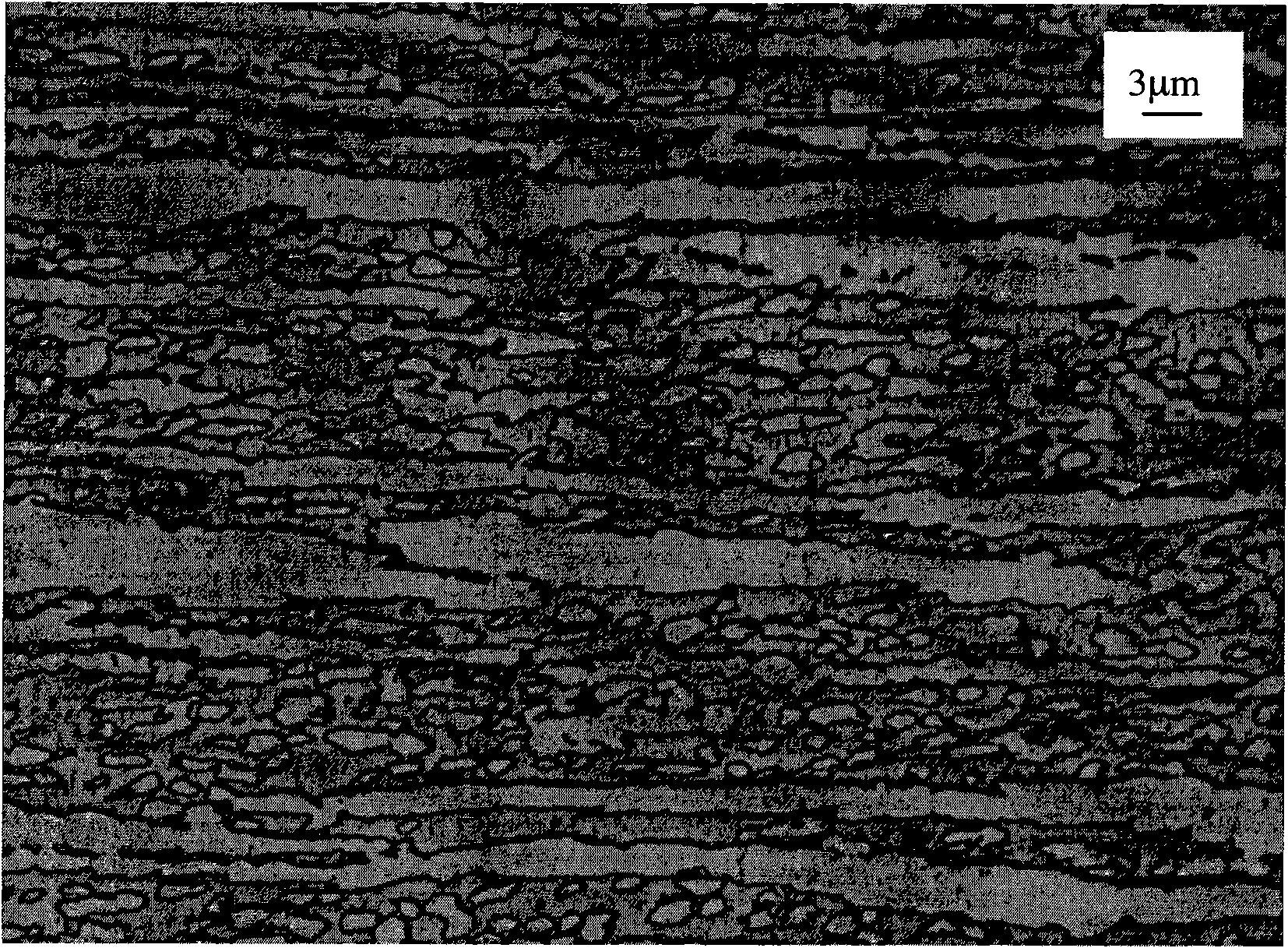

[0031] Use vacuum induction furnace, electric furnace-AOD smelting or electric furnace-AOD-VOD to smelt stainless steel, cast billets, hot-roll to 4mm, solid solution + pickling at about 1050°C, cold-roll to 1.5mm, annealing + pickling at about 1050°C, Polished finish.

[0032] The chemical composition of the duplex stainless steel in the embodiment of the present invention is shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Login to View More

Abstract

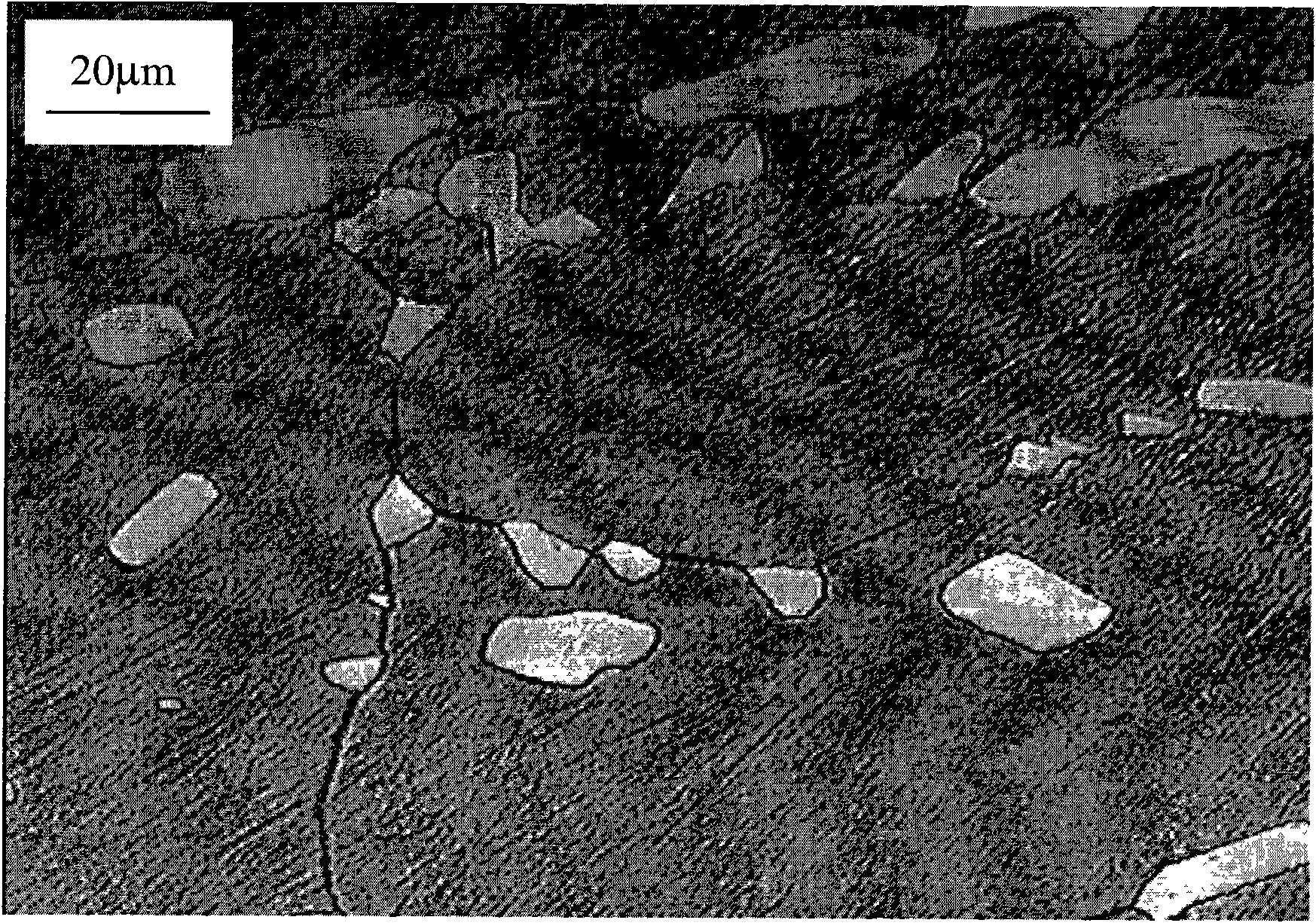

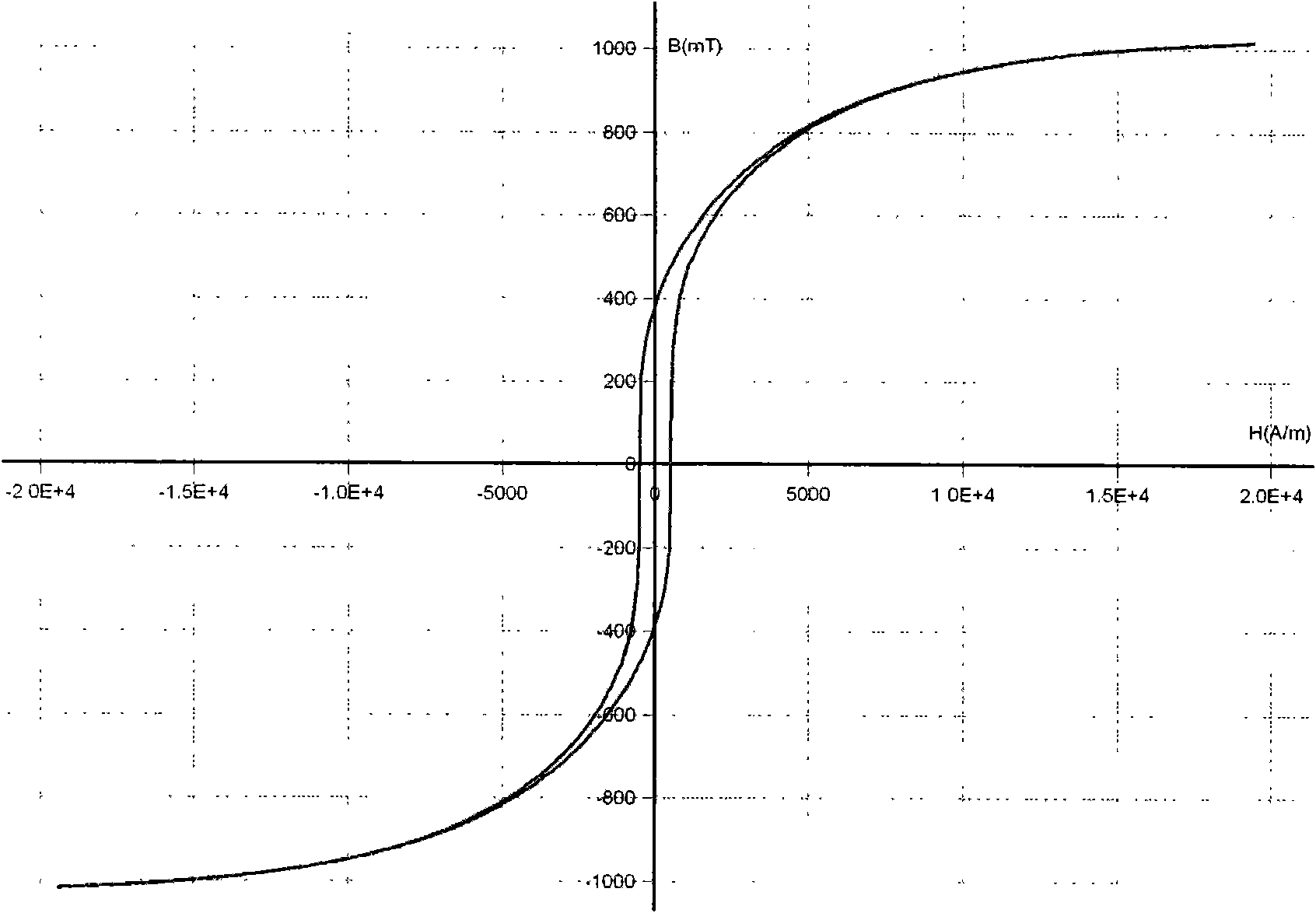

The invention provides a duplex stainless steel with special magnetic property, which comprises the following chemical compositions in percentage by weight: less than or equal to 0.12 percent of C+N, less than or equal to 1.0 percent of Si, 2.0 to 6.0 percent of Mn, less than or equal to 0.04 percent of P, less than or equal to 0.01 percent of S, 3.0 to 7.0 percent of Ni, 22.0 to 27.0 percent of Cr, less than or equal to 2.0 percent of Cu, less than or equal to 2.0 percent of Mo, less than or equal to 2.0 percent of W, less than 0.1 percent of Ce or less than 0.006 percent of B, and the balance of Fe and inevitable impurities, wherein the equivalent ratio of Cr to Ni (Creq / Nieq) is between 3.1 and 3.8. Under the control of the chemical compositions, ferrite volume content of materials in the state of cold rolling and anneal is between 68 and 85 percent, while the saturation magnetic induction density is between 0.72 and 1.0 T. The duplex stainless steel has good hot forming property, low hardness, good plasticity and anti-counterfeiting property, and is suitable for coining.

Description

Technical field [0001] The present invention relates to stainless steel materials. Specifically, the present invention relates to a duplex stainless steel with special magnetic properties. Background technique [0002] With the improvement of people's living standards and aesthetic concepts, entertainment, commerce and other industries are becoming increasingly prosperous, and the performance requirements for coins used in entertainment, commerce and other facilities are constantly increasing, and stainless steel coins have emerged as the times require. Stainless steel is increasingly recognized and loved by the market for its lower cost, anti-corrosion and wear resistance, good processing performance and surface gloss. In many countries and regions, stainless steel has long been used as a material for manufacturing coins such as game machines. The commonly used stainless steels are 430 ferritic stainless steel and 304 austenitic stainless steel. [0003] However, there is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/58

Inventor 林刚沈继程江来珠崔健

Owner BAOSHAN IRON & STEEL CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com