Sawtooth metal wire for producing all-steel sawtooth card clothing

A metal wire and sawtooth technology, applied in the field of sawtooth metal wire, can solve the problems of usability degradation and material cost increase, and achieve the effect of material cost reduction, high hardness, and elimination of steel defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

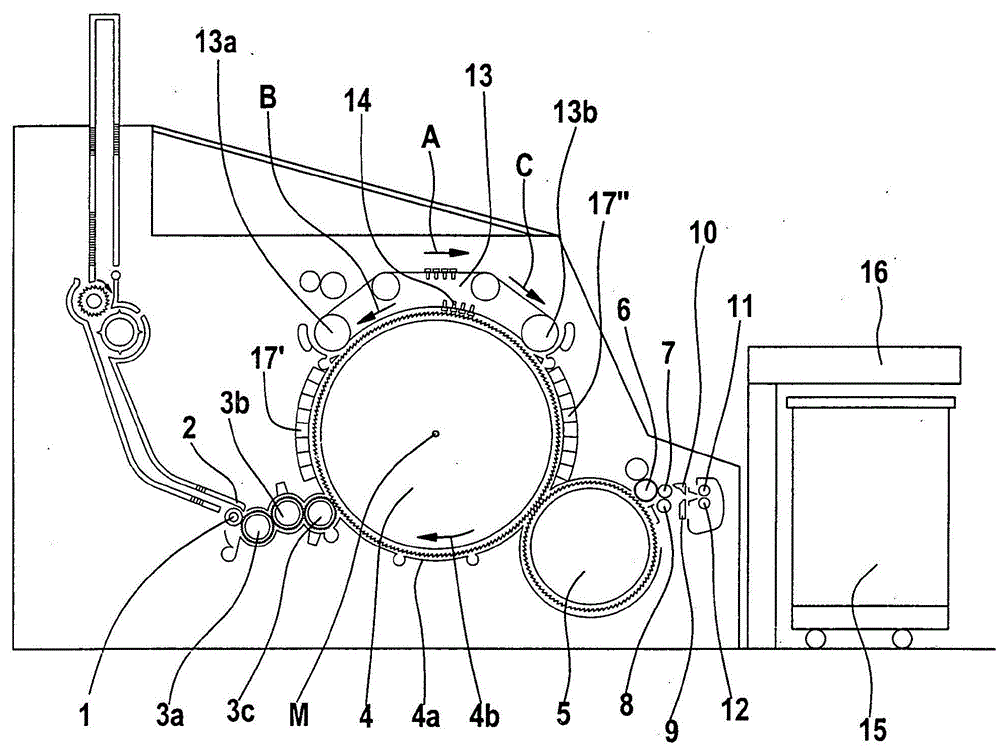

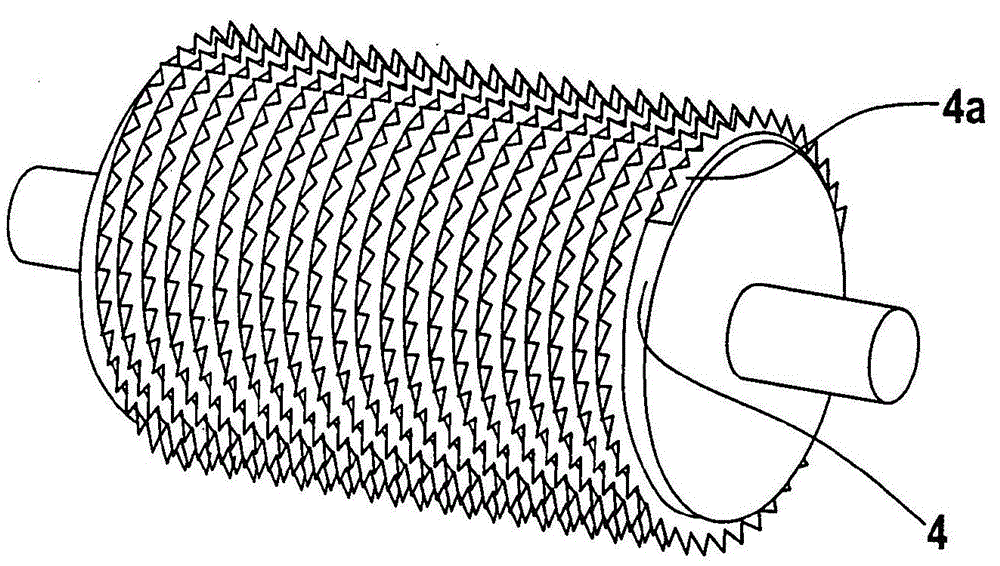

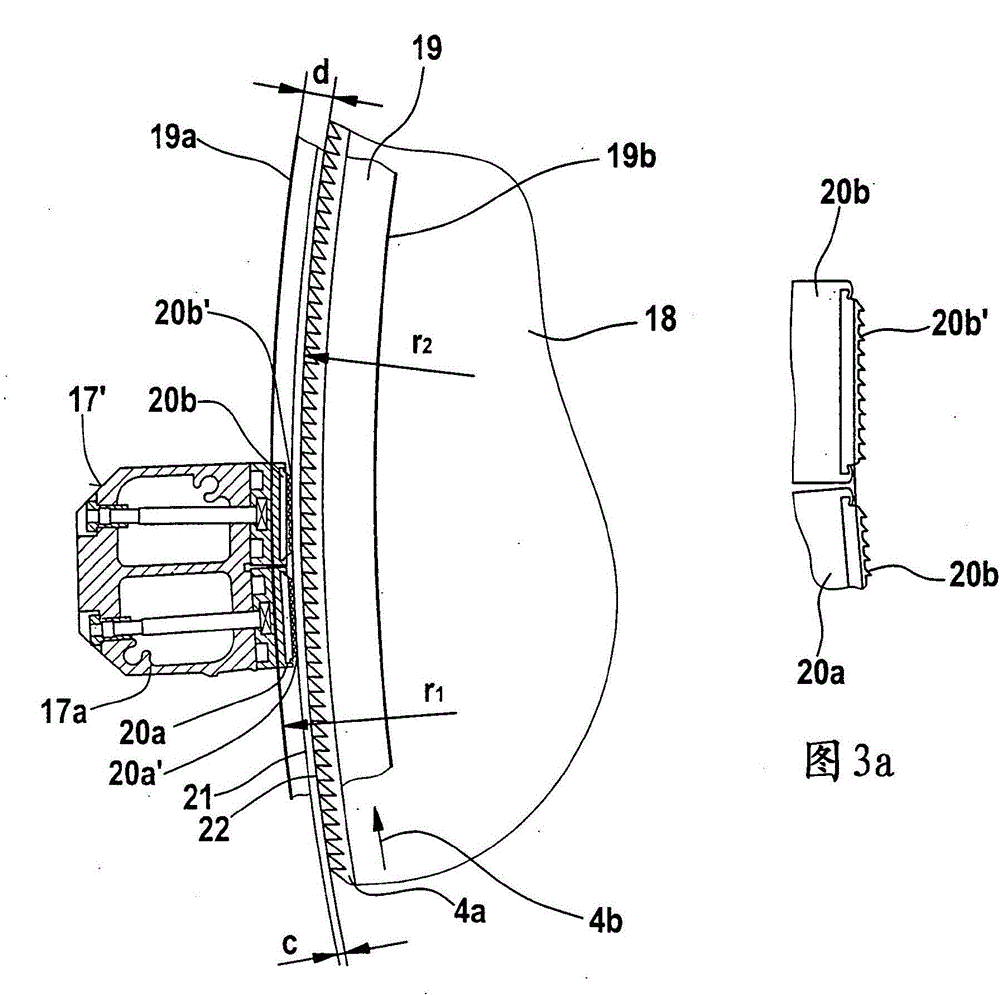

[0019] According to a preferred embodiment of the present invention, a serrated wire is provided for producing all-steel sawtooth clothing for flat carding machines or roller carding machines, the serrated wire is made of carbon, silicon , manganese and chromium alloy steel, wherein the alloy steel contains: 0.93-1.10% by weight carbon; 0.15-0.35% by weight silicon; 0.20-0.45% by weight manganese; 1.35-1.60% by weight of chrome.

[0020] Preferably, the alloy steel contains: 0.93-1.05% by weight carbon; 0.15-0.35% by weight silicon; 0.25-0.45% by weight manganese; 1.35-1.60% by weight chromium.

[0021] Preferably, the alloy steel contains less than 0.10% molybdenum by weight.

[0022] Preferably, the alloy steel contains less than 0.05% by weight of aluminum.

[0023] Preferably, the alloy steel contains less than 0.30% by weight copper.

[0024] Preferably, the alloy steel contains: 0.95-1.10% by weight carbon; 0.15-0.35% by weight silicon; 0.20-0.40% by weight manganese;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com