Preparation method of N-isopropyl acrylamide polymer/polyvinyl alcohol composite hydrogel and product thereof

A technology of isopropylacrylamide and composite hydrogel, which is applied in the preparation of N-isopropylacrylamide polymer/polyvinyl alcohol composite hydrogel and its product field, can solve the problem of unsuitable energy-saving glass doors, windows, and shapes. Instability, poor mechanical properties and other problems, to reduce lighting and heating energy consumption, stable properties, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the preparation of poly-N-isopropylacrylamide / polyvinyl alcohol composite hydrogel

[0021] Dilute 5mL of glutaraldehyde with water to make a solution with a volume fraction of 5%; dilute 20mL of methanol with water to make a solution with a volume fraction of 50%; dilute 2mL of glacial acetic acid with water to make a solution with a volume fraction of 10% ; Dilute 2 mL of concentrated sulfuric acid with water to make a solution with a volume fraction of 20%; mix the above four solutions evenly to obtain an organic crosslinking agent;

[0022] Mix 10 g of 1% poly(N-isopropylacrylamide) aqueous solution with 10 g of 10% polyvinyl alcohol 1799 (average degree of polymerization: 1750±50) aqueous solution and add dropwise 0.5 g of organic cross-linking agent, stirred evenly, and left to stand for 24 hours to obtain poly-N-isopropylacrylamide / polyvinyl alcohol composite hydrogel.

[0023] After testing, the LCST of the obtained composite hydrogel was 33.2°C; ...

Embodiment 2

[0024] Embodiment 2, the preparation of poly(N-isopropylacrylamide-methyl acrylate) / polyvinyl alcohol composite hydrogel

[0025] According to the method described in Example 1, poly(N-isopropylacrylamide-methyl acrylate) is used to replace poly-N-isopropylacrylamide to obtain poly(N-isopropylacrylamide-methyl acrylate) / Polyvinyl alcohol composite hydrogel.

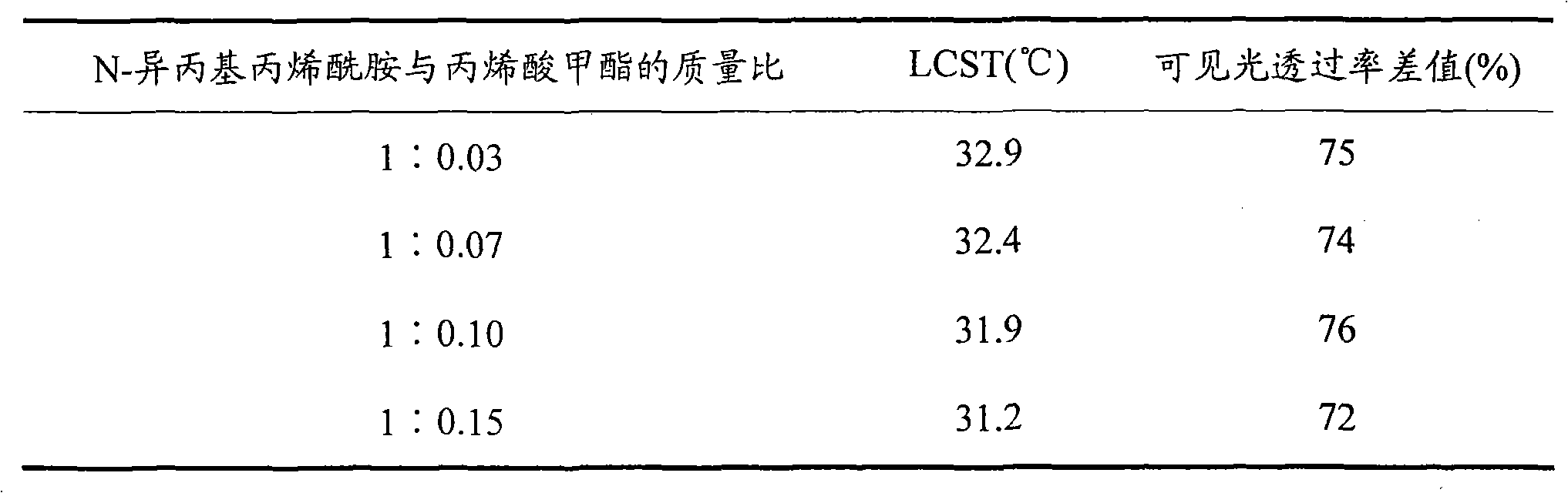

[0026] After testing, the LCST of the composite hydrogel prepared from poly(N-isopropylacrylamide-methyl acrylate) with different monomer mass ratios is shown in Table 1; the composite hydrogel film with a thickness of 1mm, The difference in visible light transmittance between the transparent state and the white turbid state is shown in Table 1.

[0027] Table 1. Properties of composite hydrogels prepared from poly(N-isopropylacrylamide-methyl acrylate) with different monomer mass ratios

[0028]

Embodiment 3

[0029] Embodiment 3, the preparation of poly(N-isopropylacrylamide-ethyl acrylate) / polyvinyl alcohol composite hydrogel

[0030] According to the method described in Example 1, poly(N-isopropylacrylamide-ethyl acrylate) was substituted for poly-N-isopropylacrylamide to obtain poly(N-isopropylacrylamide-ethyl acrylate) / Polyvinyl alcohol composite hydrogel.

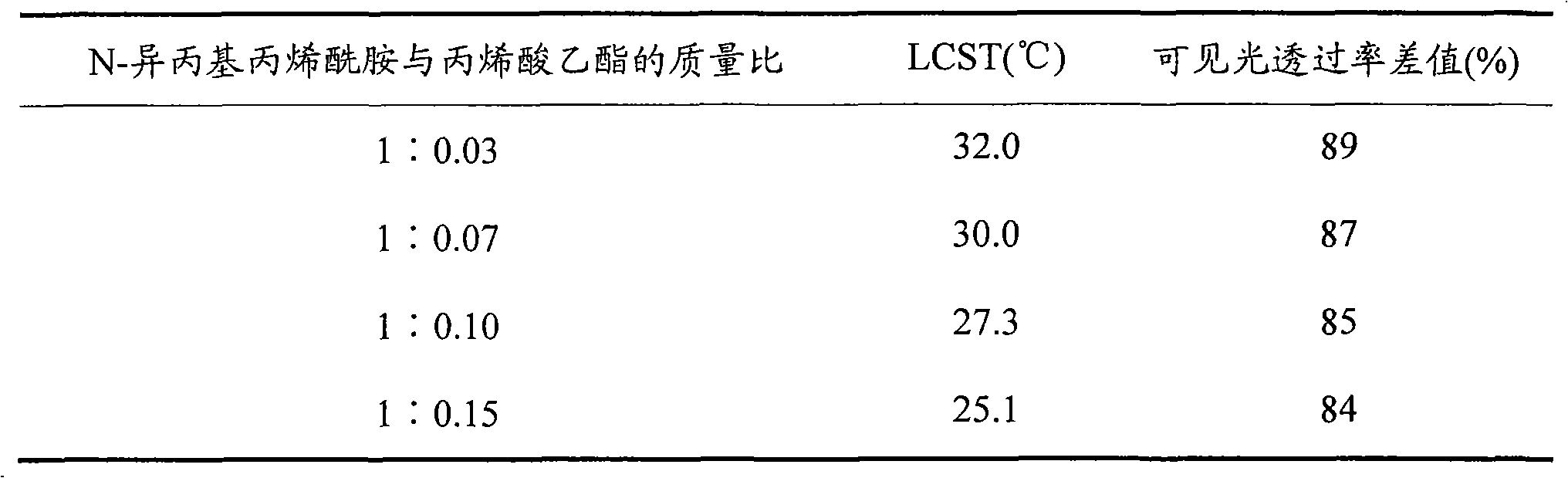

[0031] After testing, the LCST of the composite hydrogel prepared from poly(N-isopropylacrylamide-ethyl acrylate) with different monomer mass ratios is shown in Table 2; the composite hydrogel film with a thickness of 1mm, The difference in visible light transmittance between the transparent state and the white turbid state is shown in Table 2.

[0032] Table 2. Properties of composite hydrogels prepared from poly(N-isopropylacrylamide-ethyl acrylate) with different monomer mass ratios

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com