Cefoxitin acid preparation method

A technology of cefoxitin acid and acetyl head, which is applied in the field of preparing cefoxitin acid, can solve the problems such as tetrahydrofuran cannot be reused, the cost of cefoxitin acid is high, and the yield of final product is reduced, and the social and economic benefits are remarkable, The effect of easy recycling and material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

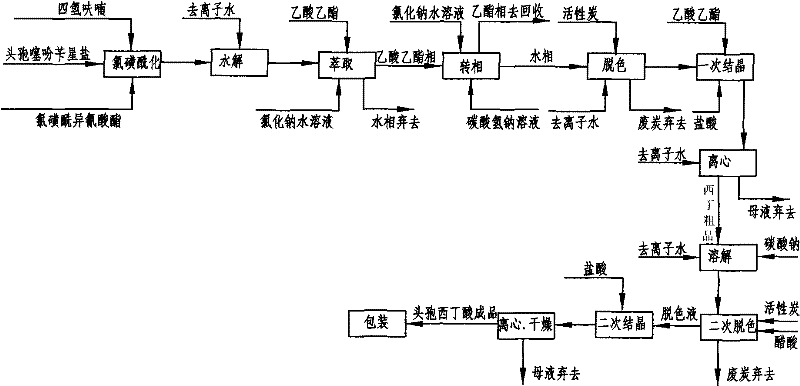

Image

Examples

Embodiment 1

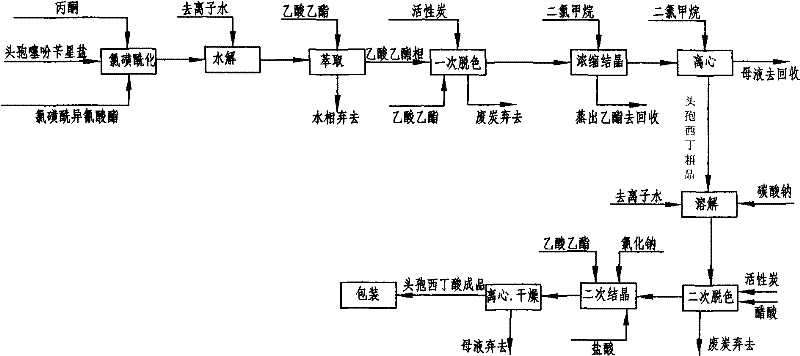

[0043] Embodiment 1: as figure 2 Shown, this is that reaction solvent, 7-alpha-methoxy-3-deacetyl cephalothin benzine salt is the method for starting raw material preparation cefoxitin acid by acetone and comprises the following steps:

[0044] a. Chlorosulfonylation: Add 50 g of 7-α-methoxy-3-deacetyl cephalothin benzathine salt to 300 ml of acetone at room temperature 25°C, and add chlorosulfonyl when cooled to -50~-60°C 26g of isocyanate, under the stirring state, use liquid nitrogen to control the temperature to react at -60°C ~ -30°C, keep stirring for 60 minutes and then take a sample for detection. When the initial raw material 7-α-methoxy-3-deacetyl cephalothin End reaction when star salt ≤ 1.0%;

[0045] b. Hydrolysis: Pour the reaction solution after the above reaction into 100ml deionized water, stir, use cold salt water to control the temperature at 0-20°C to carry out the hydrolysis reaction, keep stirring for 60 minutes and then take a sample for detection. Whe...

Embodiment 2

[0052] Embodiment 2: the difference between this embodiment and embodiment 1 is:

[0053] a. Chlorosulfonylation: at room temperature 25°C, add 50g of 7-α-methoxy-3-deacetylcephalothin benzathine salt to 500ml of acetone, add chlorosulfonyl when cooled to -50~-60°C 35g of isocyanate, under stirring, use liquid nitrogen to control the temperature to react at -60°C ~ -30°C, take a sample for detection, when the initial raw material 7-α-methoxy-3-deacetyl cephalothin benzathine salt ≤ 1.0% end the reaction;

[0054] b. Hydrolysis: Pour the reaction solution after the above reaction into 100ml deionized water, stir, and use cold salt water to control the temperature at 0-20°C to carry out the hydrolysis reaction, keep stirring for 60 minutes and then take a sample for detection. When the intermediate N- The reaction ends when the chlorosulfonic acid derivative is ≤1.0%;

[0055] c. Extraction: Add 600ml of ethyl acetate to the above hydrolyzate, stir for 10 minutes and then filt...

Embodiment 3

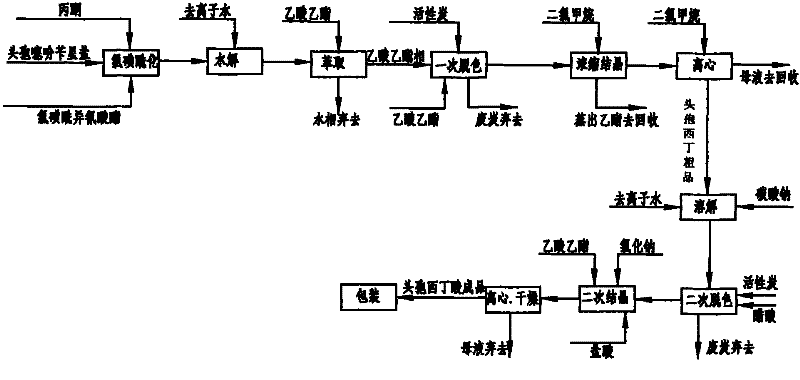

[0061] Embodiment 3: the differences between this embodiment and embodiment 1 are:

[0062] a. Chlorosulfonylation: at room temperature 25°C, add 50g of 7-α-methoxy-3-deacetylcephalothin benzathine salt to 450ml of acetone, add chlorosulfonyl when cooled to -50~-60°C 40g of isocyanate, under stirring, use liquid nitrogen to control the temperature to react at -60°C ~ -30°C, take a sample for detection, when the initial raw material 7-α-methoxy-3-deacetyl cephalothin benzathine salt ≤ 1.0% end the reaction;

[0063] b. Hydrolysis: Pour the above-mentioned reaction solution into 100ml deionized water, stir, and use cold salt water to control the temperature at about 10°C to carry out the hydrolysis reaction. After stirring for 60 minutes, take a sample to detect when the intermediate N-chlorosulfur The reaction ends when the acid derivative is ≤1.0%;

[0064] c. Extraction: Add 800 ml of ethyl acetate to the above hydrolyzate, stir for 10 minutes and then filter. The filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com