Method for preparing dibenzyl disulfide

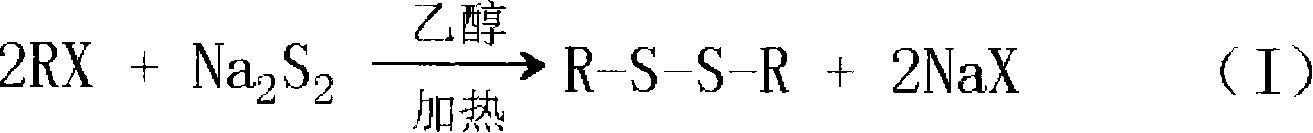

A technology of dibenzyl disulfide and benzyl chloride, which is applied in the field of preparation of dibenzyl disulfide, can solve the problems of long operation period, low yield of disulfide organic compounds, waste of raw materials, etc. The effect of time and temperature reduction, easy control of the reaction process, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of Na 2 S 2

[0028] Put 250 milliliters of water and 100 grams of sodium sulfide in a 500 milliliter flask equipped with an electric stirrer, a thermometer and a reflux device, heat and stir to become a solution, then add 41 grams of sulfur powder (the same molar number as sodium sulfide) and react at 65 ° C 1 hour becomes Na 2 S 2 aqueous solution;

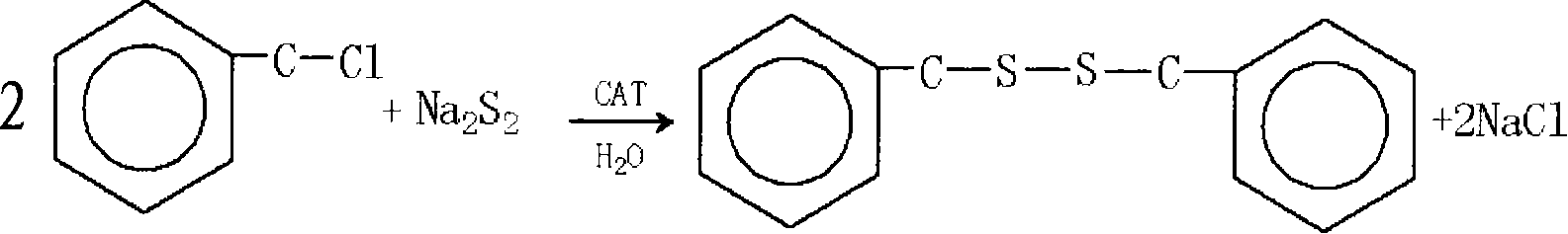

[0029] 2. Preparation of Dibenzyl Disulfide

[0030] In the above Na 2 S 2 Add 2.82 grams of CAT (Na 2 S 2 2% of weight) and 324 grams (2 times Na 2 S 2 moles) benzyl chloride, stirred and reacted at 50°C for 10 minutes, cooled the feed liquid to 20°C, neutralized the feed liquid with hydrochloric acid to neutrality, separated the water phase, washed the organic phase with water, dried, and recrystallized with ethanol to obtain Symmetrical dibenzyl disulfide, its yield is 85%, the content of dibenzyl disulfide is 98.2%, M.P.71~72°C, the product is light yellow crystal, and the sensory feature is ...

Embodiment 2

[0032] 1. Preparation of Na 2 S 2

[0033] Operation method is with embodiment 1;

[0034] 2. Preparation of Dibenzyl Disulfide

[0035] 141 g Na 2 S 2 After mixing with water to make an aqueous solution, add 8.46 grams of CAT (Na 2 S 2 6% of weight) and 270 grams of (Na 2 S 2 The molar ratio to benzyl chloride is 0.6) benzyl chloride, stirred and reacted at 30°C for 40 minutes, cooled the feed liquid to 20°C, neutralized the feed liquid with hydrochloric acid to neutrality, separated the water phase, washed the organic phase with water, dried, and then Recrystallize with ethanol to obtain symmetrical dibenzyl disulfide, the yield is 90%, the content of dibenzyl disulfide is 98.5%, M.P.71~72℃, the product is light yellow crystal, and the sensory feature is relatively strong burnt sweet smell.

Embodiment 3

[0037] 1. Preparation of Na 2 S 2

[0038] Operation method is with embodiment 1;

[0039] 2. Preparation of Dibenzyl Disulfide

[0040] 141 g Na 2 S 2 After mixing with water to make an aqueous solution, add 4.23 grams of CAT (Na 2 S 2 3% by weight) and 203 grams of (Na 2 S 2 The molar ratio to benzyl chloride is 0.8) benzyl chloride, stirred and reacted at 40°C for 25 minutes, cooled the feed liquid to 20°C, neutralized the feed liquid with hydrochloric acid to neutrality, separated the water phase, washed the organic phase with water, dried, and then Recrystallize with ethanol to obtain symmetrical dibenzyl disulfide, the yield is 87%, the content of dibenzyl disulfide is 98.13%, M.P.71~72℃, the product is light yellow crystal, and the sensory feature is relatively strong burnt sweet smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com