Steel ladle using casting material prefabricated lower casting nozzle brick and producing method thereof

A technology of ladle pouring and production method, applied in the field of refractory materials, can solve problems such as complex formula, achieve the effects of simple process, increased safety factor and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

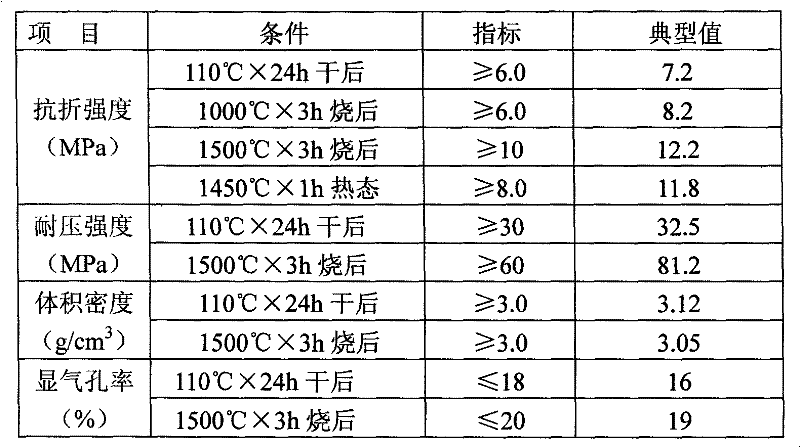

Examples

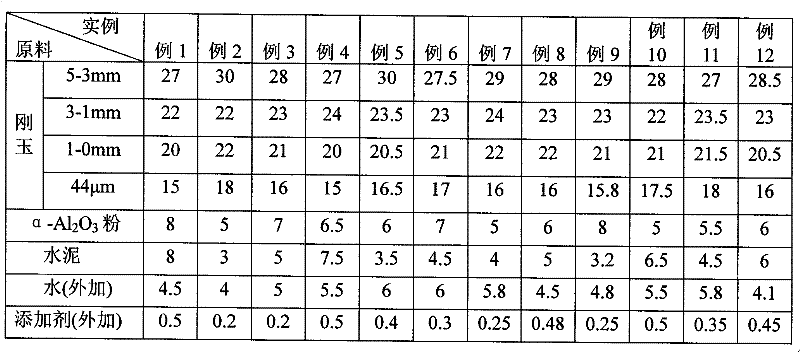

Embodiment 1

[0025] Embodiment 1: A prefabricated lower sprue brick for ladle pouring material. The raw material composition is shown in the corresponding data in Table 2. Taking 100kg of raw material as an example, 27kg of corundum with a particle size of 5-3mm, 22kg of corundum with a particle size of 3-1mm, 1- 0mm corundum 20kg, 44μm corundum 15kg, α-Al 2 o 3 Powder 8kg, pure calcium aluminate cement 8kg; add water 4.5kg, additive 0.5kg.

[0026] α-Al in the table 2 o 3 The particle size of the powder is 5 μm, the cement is pure calcium aluminate with a particle size of 44 μm, and the additive is a mixture of sodium hexametaphosphate and sodium tripolyphosphate, and the weight ratio of the two is 2:1.

[0027] The production method comprises the steps of:

[0028] (1) Mixing material: Weigh the material according to the raw material composition, add tabular alumina and additives into the mixer under stirring, and dry mix for 3-5 minutes; then add water while stirring, and wet mix fo...

Embodiment 2

[0034] Embodiment two: raw material composition sees corresponding data in table 2, differs from embodiment one in that:

[0035] The weight ratio of sodium hexametaphosphate and sodium tripolyphosphate in the additive used is 2:1.

[0036] The production method comprises the steps of:

[0037] (1) Mixing material: Weigh the material according to the raw material composition, add tabular alumina and additives into the mixer under stirring, and dry mix for 3-4 minutes; then add water while stirring, and wet mix for 3-4 minutes; then add α-Al 2 o 3 powder, pure calcium aluminate cement, stir for 8-9 minutes, and discharge; when stirring, the rotation speed is 40-50r / min;

[0038] (2) Vibration forming: Fix the steel shell of the lower casting brick in the mold, open the vibrating table, continuously inject the slurry for pouring, vibrate forming, and then demould; the power of the vibrating table is 5KW, and the vibrating table is first Vibrate for 3-4min, with an amplitude r...

Embodiment 3

[0042] Embodiment three: raw material composition sees corresponding data in table 2, differs from embodiment one in that:

[0043] The weight ratio of sodium hexametaphosphate and sodium tripolyphosphate in the additive used is 1.5:1.

[0044] The production method comprises the steps of:

[0045] (1) Mixing material: Weigh the material according to the raw material composition, add platy corundum and additives into the mixer under stirring, and dry mix for 4 minutes; then add water while stirring, and wet mix for 4 minutes; then add α-Al 2 o 3powder, pure calcium aluminate cement, stirred for 9 minutes, and discharged; the speed of stirring was 60r / min;

[0046] (2) Vibration forming: Fix the steel shell of the lower casting brick in the mold, open the vibrating table, continuously inject the slurry for pouring, vibrate forming, and then demould; the power of the vibrating table is 5KW, and the vibrating table is first Vibrate for 4 minutes, with an amplitude range of 4mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com