Concrete high-efficiency expanding agent and preparation method thereof

A high-efficiency expansion agent and concrete technology, applied in the direction of solid waste removal, etc., can solve the problems of rising price of natural anhydrite, cost pressure of expansion agent production enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Embodiment 1 of the present invention: the preparation of concrete high-efficiency expansion agent:

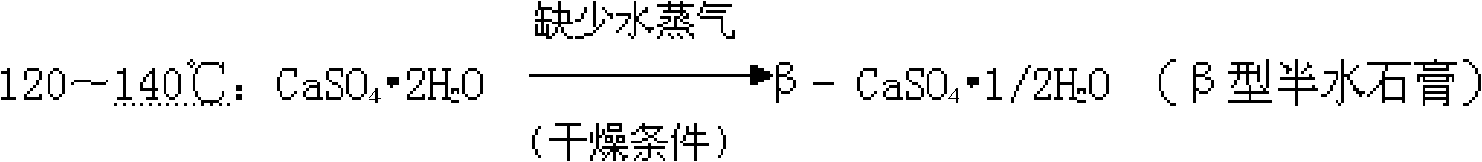

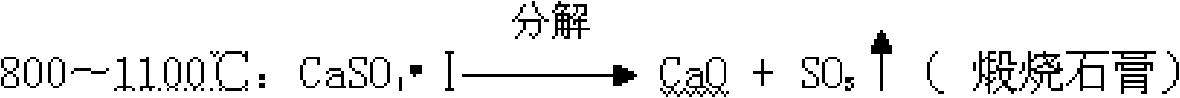

[0076] Take first-grade bauxite (Al 2 o 3 Content 83%) 47kg and limestone 53kg, mix, grind together until the fineness is 4900 hole sieve ≤ 8%, then make raw meal balls with a diameter of φ10 ~ 15mm, calcined in a rotary kiln at 1380°C for 50 minutes , to obtain special high-alumina clinker; take phosphogypsum, and calcined at 650°C for 80 minutes; mix 60kg of calcined phosphogypsum with 40kg of special high-alumina clinker, and use a ball mill to grind until the residue on the 4900-hole sieve is ≤10%. That is to say, the concrete high-efficiency expansion agent conforming to JC476-2001 expansion agent standard is obtained, the 7-day limit expansion rate is more than 0.025%, and the expansion agent content is 6-8%.

Embodiment 2

[0077] Embodiment 2 of the present invention: get first-grade bauxite (Al 2 o 3 content 75%) 44kg and limestone 56kg, mixed and ground together until the fineness is 4900 mesh sieve residue < 10%, then made into raw meal balls of φ10 ~ 15mm, calcined at 1350 ℃ in Liboer kiln for 40 Minutes to get special high alumina clinker; take phosphogypsum, calcined at 600°C for 70 minutes; mix 65kg of calcined phosphogypsum with 35kg of special high alumina clinker, and use a ball mill to grind until the residue on the 4900-hole sieve <12% , that is, a high-efficiency concrete expansion agent that meets the JC476-2001 expansion agent standard.

Embodiment 3

[0078] Embodiment 3 of the present invention: get bauxite (Al 2 o 3 content 70%) 50kg and limestone 50kg, mix and grind together until the fineness is 4900 hole sieve sieve ≤ 10%, then make raw meal balls of φ10 ~ 15mm, calcined in a rotary kiln at 1400°C for 0.5 hours, Obtain special high-alumina clinker; take phosphogypsum, calcined at 700°C for 1 hour; mix 60 kg of calcined phosphogypsum with 40 kg of special high-alumina clinker, and use a ball mill to grind until the residue on the 4900-hole sieve ≤ 12%, that is Concrete high-efficiency expansion agent that meets JC476-2001 expansion agent standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com