Carbon nanotube cotton and preparation method thereof

A technology of carbon nanotubes and multi-walled carbon nanotubes, which is applied in the synthesis and application of carbon nanomaterials, can solve problems such as numerous steps, difficulty in obtaining macroscopic bulk samples, and constraints on the wide application of carbon nanotubes to achieve cyclic compression performance Good, low density, low thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

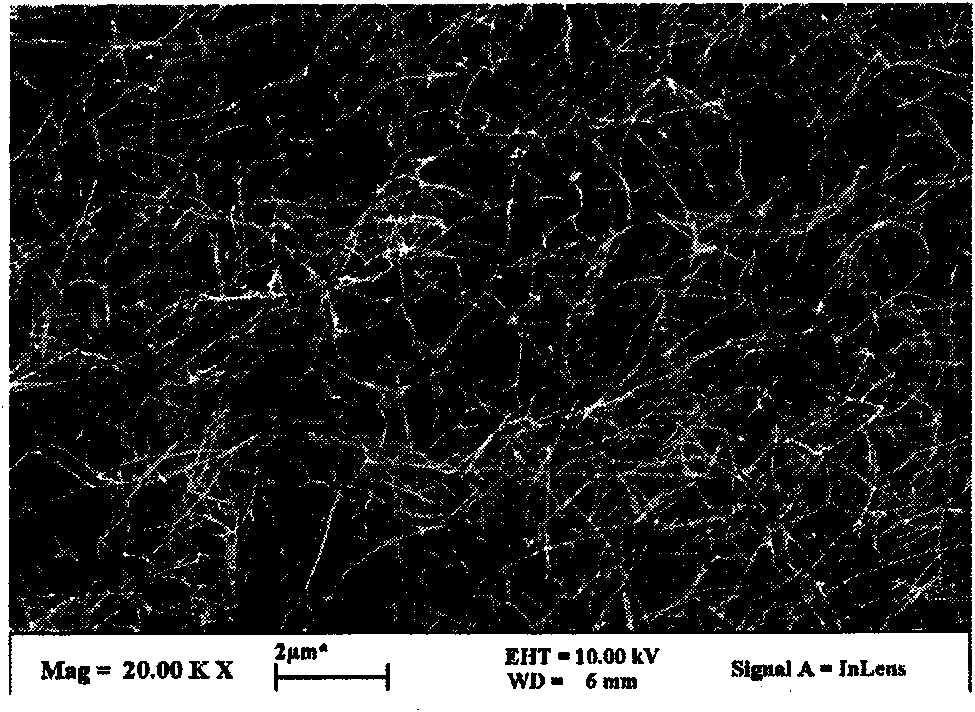

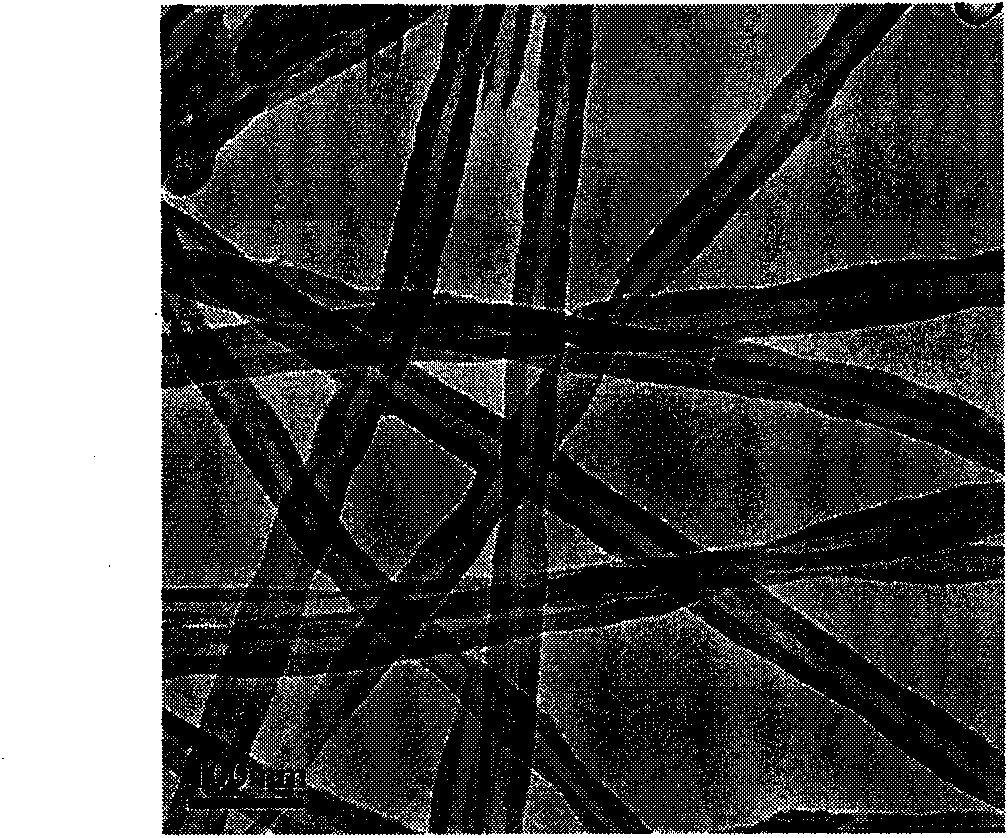

[0031] Weigh 6g of ferrocene powder and dissolve it in 100mL of dichlorobenzene solution. After the ferrocene is fully dissolved, a brownish yellow solution is formed to obtain a ferrocene / dichlorobenzene carbon source solution with a concentration of 60mg / mL for future use. Put the quartz substrate into the quartz reaction chamber of the reaction furnace, and seal the reaction chamber. Introduce argon gas with a flow rate of 1000mL / min into the reaction chamber to exhaust the air in the reaction chamber, while heating the reaction furnace. When the temperature of the reaction chamber reaches 860° C., adjust the flow rate of argon to 2000 mL / min, and at the same time, feed hydrogen at a flow rate of 300 mL / min. Inject the carbon source solution into the reaction chamber with a precision syringe pump at a rate of 0.13 mL / min. After reacting for 4 hours, turn off the hydrogen, adjust the flow of argon to 50 mL / min, and let the product cool down to room temperature with the furn...

Embodiment 2

[0034] Weigh 6g of ferrocene powder and dissolve it in 100mL of dichlorobenzene solution. After the ferrocene is fully dissolved, a brownish yellow solution is formed to obtain a ferrocene / dichlorobenzene carbon source solution with a concentration of 60mg / mL for future use. Put the quartz substrate into the quartz reaction chamber of the reaction furnace, and seal the reaction chamber. Introduce argon gas with a flow rate of 1000mL / min into the reaction chamber to exhaust the air in the reaction chamber while heating the reaction furnace. When the temperature of the reaction chamber reaches 860° C., adjust the flow rate of argon to 2000 mL / min, and at the same time, feed hydrogen at a flow rate of 500 mL / min. Inject the carbon source solution into the reaction chamber with a precision syringe pump at a rate of 0.13 mL / min. After reacting for 4 hours, turn off the hydrogen, adjust the flow of argon to 50 mL / min, and let the product cool down to room temperature with the furna...

Embodiment 3

[0037] Weigh 6g of ferrocene powder and dissolve it in 100mL of dichlorobenzene solution. After the ferrocene is fully dissolved, a brownish yellow solution is formed to obtain a ferrocene / dichlorobenzene carbon source solution with a concentration of 60mg / mL for future use. Put the quartz substrate into the quartz reaction chamber of the reaction furnace, and seal the reaction chamber. Introduce argon gas with a flow rate of 1000mL / min into the reaction chamber to exhaust the air in the reaction chamber while heating the reaction furnace. When the temperature of the reaction chamber reaches 860° C., adjust the flow rate of argon to 2000 mL / min, and at the same time, feed hydrogen at a flow rate of 300 mL / min. Use a precision syringe pump to inject the carbon source solution into the reaction chamber at a rate of 0.25 mL / min; after 4 hours of reaction, turn off the hydrogen, adjust the argon flow to 50 mL / min, and let the product cool down to room temperature with the furnace....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com