Flame-retardant fiber board and manufacturing method thereof

A manufacturing method and fiber technology, which is applied in the field of flame-resistant fiber boards and its manufacturing, can solve problems such as resource defects, fragility, and halogenation, and achieve the effects of wide application fields, excellent waterproof performance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

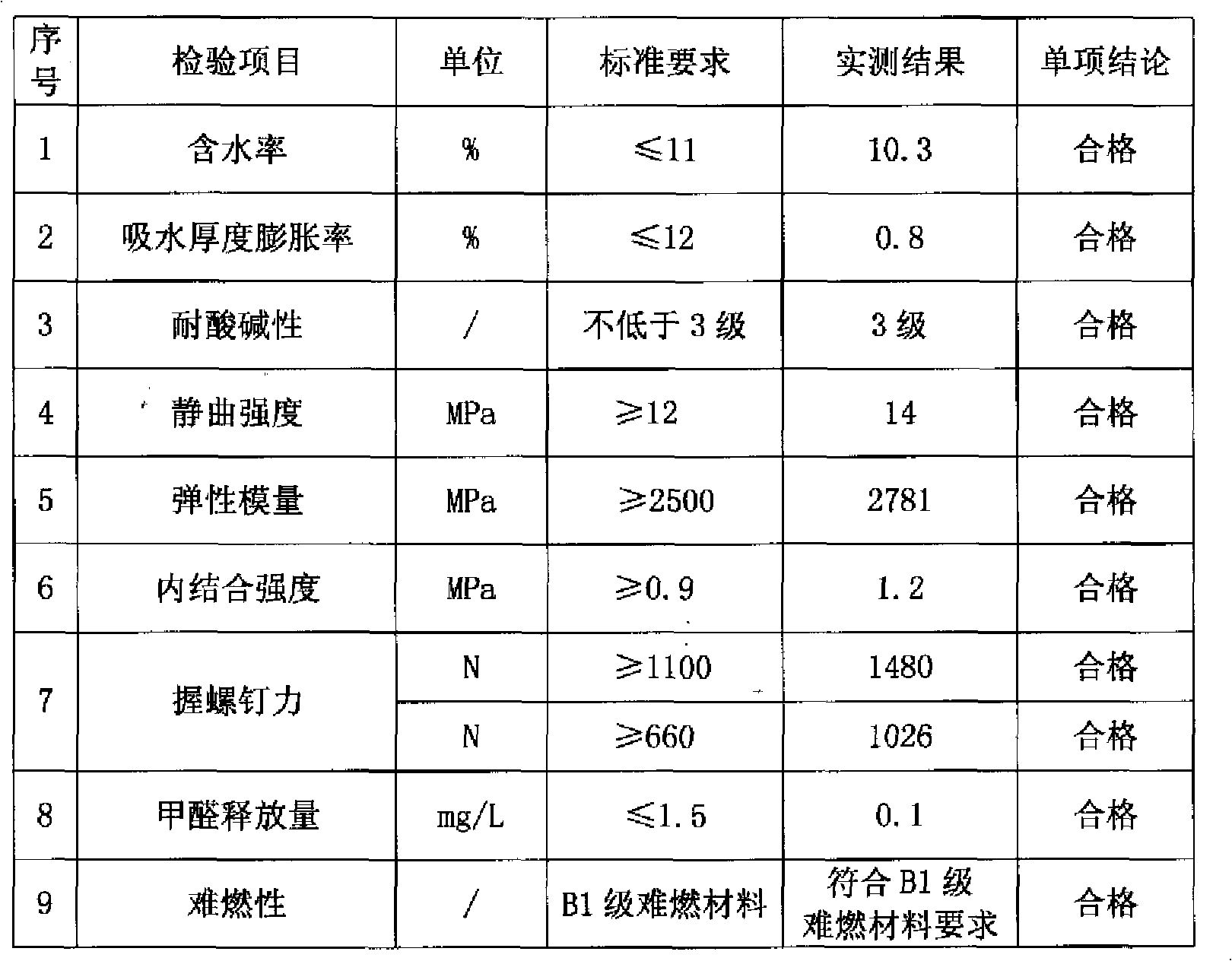

Examples

Embodiment 1

[0029] 1) Preparation of fibers: clean and dry 80 kg of crop cotton stalks, and then pulverize them into straw fibers through a pulverizer;

[0030] 2) Preparation of inorganic adhesive: 80kg of 80% magnesium oxide, 80kg of 25% magnesium sulfate aqueous solution, 5kg of active silicon dioxide, 0.5kg of silicone water repellent and 0.5kg of plasticizer were mixed and stirred. Inorganic adhesive;

[0031] 3) mixing and stirring the fiber and inorganic adhesive obtained in the above steps 1 and 2, and paving after screening by a screening machine;

[0032] 4) Lay 4×4 glass fiber mesh cloth on the upper and lower surfaces of the paved slab;

[0033] 5) Finally, hot-press the sheet covered with glass fiber mesh cloth for 10 minutes at a temperature of 100°C and a pressure of 12Mpa.

Embodiment 2

[0035] 1) Preparation of fibers: 100kg of wood is cleaned and dried, and then pulverized by a pulverizer to make wood wool fibers;

[0036] 2) Preparation of inorganic adhesive: 100kg of magnesium oxide with a content of 85%, 130kg of aqueous magnesium sulfate solution with a content of 26%, 10kg of active silicon dioxide, 1kg of silicone water repellent and 0.8kg of plasticizer were mixed and stirred. Inorganic adhesive;

[0037] 3) mixing and stirring the fiber and inorganic adhesive obtained in the above steps 1 and 2, and paving after screening by a screening machine;

[0038] 4) Spread 5×5 glass fiber mesh cloth on the upper and lower surfaces of the paved slab;

[0039] 5) Finally, hot-press the plate covered with glass fiber mesh cloth for 20 minutes at a temperature of 105°C and a pressure of 22Mpa.

Embodiment 3

[0041] 1) Preparation of fibers: 120kg of wood is cleaned and dried, and then pulverized by a pulverizer to make wood wool fibers;

[0042] 2) Preparation of inorganic adhesive: 120kg of magnesium oxide with a content of 90%, 200kg of magnesium sulfate aqueous solution with a content of 28%, 30kg of active silicon dioxide, 2kg of silicone water repellent and 1.5kg of plasticizer were mixed and stirred. Inorganic adhesive;

[0043] 3) mixing and stirring the fiber and inorganic adhesive obtained in the above steps 1 and 2, and paving after screening by a screening machine;

[0044] 4) Lay a 4×4 metal grid on the upper and lower surfaces of the paved slab;

[0045] 5) Finally, hot-press the plate covered with the metal grid for 25 minutes at a temperature of 110°C and a pressure of 30Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com