Preparation method of polysaccharose nanometer antichlor for industrial water treatment

A technology for industrial water treatment and dechlorination agent, applied in the field of industrial water treatment, can solve problems such as difficulty in removal, difficulty in chloride ion, etc., achieve the effect of obvious dechlorination effect and meet the requirements of hydraulic test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

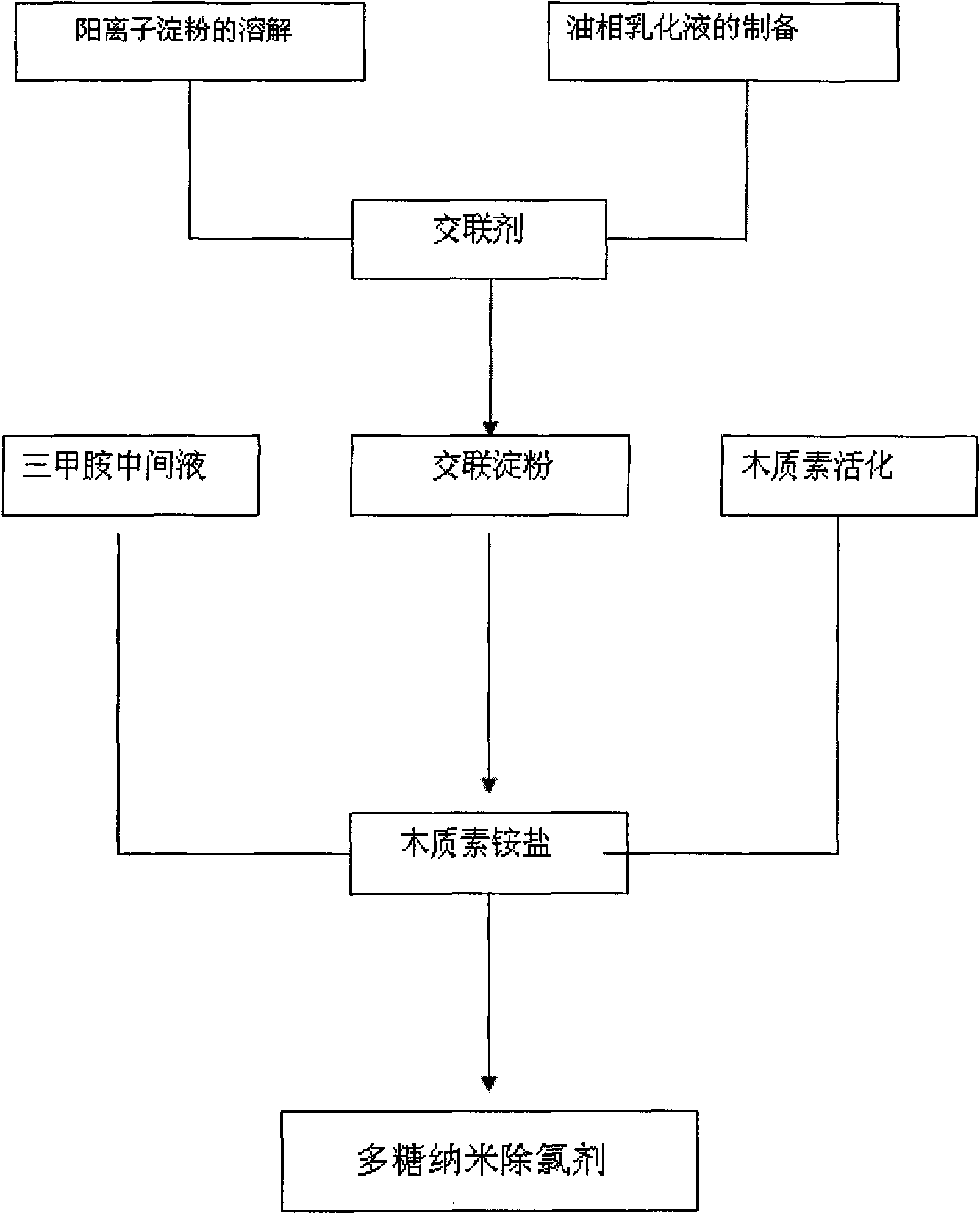

Image

Examples

Embodiment 1

[0022] (1) Preparation method of cross-linked cationic starch granules

[0023] Soluble cationic starch (Hao Rui Food Co., Ltd., Longteng Economic Development Zone, Changli County, Hebei Province) 10 grams is made into a 10% aqueous solution, heated in a boiling water bath until the solution is clear, and placed at room temperature;

[0024] Measure 30ml of toluene and 10ml of chloroform and mix, add surfactant Span80 (Span 80, Shanghai Hongji Chemical Co., Ltd.) accounting for 0.8% of the total volume, stir and mix to form an oil phase emulsion;

[0025] Add the above-mentioned starch hydrolyzate into 5ml oil phase emulsion and mix, continue to stir until a tiny emulsion is formed, add a cross-linking agent glyoxal accounting for 0.2% of the starch mass, continue to stir for 30 minutes, wash the emulsion with acetone and ethanol for 3-5 times , freeze-dried to obtain cross-linked starch granules;

[0026] (2) Preparation of lignin quaternary ammonium salt:

[0027] Weigh 1 ...

Embodiment 2

[0032] (1) Preparation method of cross-linked cationic starch granules

[0033] Soluble cationic starch (Hao Rui Food Co., Ltd., Longteng Economic Development Zone, Changli County, Hebei Province) 15 grams is made into a 10% aqueous solution, heated in a boiling water bath until the solution is clear, and placed at room temperature;

[0034] Measure 30ml of toluene and 10ml of chloroform and mix, add surfactant Span80 (Span 80, Shanghai Hongji Chemical Co., Ltd.) accounting for 0.7% of the total volume, stir and mix to form an oil phase emulsion;

[0035] Add the above-mentioned starch hydrolyzate into 8ml oil phase emulsion and mix, continue to stir until a tiny emulsion is formed, add cross-linking agent glyoxal accounting for 0.3% of the starch mass, continue to stir for 1 hour, wash the emulsion with acetone and ethanol for 3-5 times , freeze-dried to obtain cross-linked starch granules;

[0036] (2) Preparation of lignin quaternary ammonium salt:

[0037] Weigh 1.5 gram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com