Manufacturing method of colored polytetrafluoroethylene (PTFE) thread seal tape for winding and sintering

A technology of polytetrafluoroethylene and its production method, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problem of low density, insufficient electrical insulation and voltage resistance, and cannot be used for electrical insulation protection layers of wires and cables, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

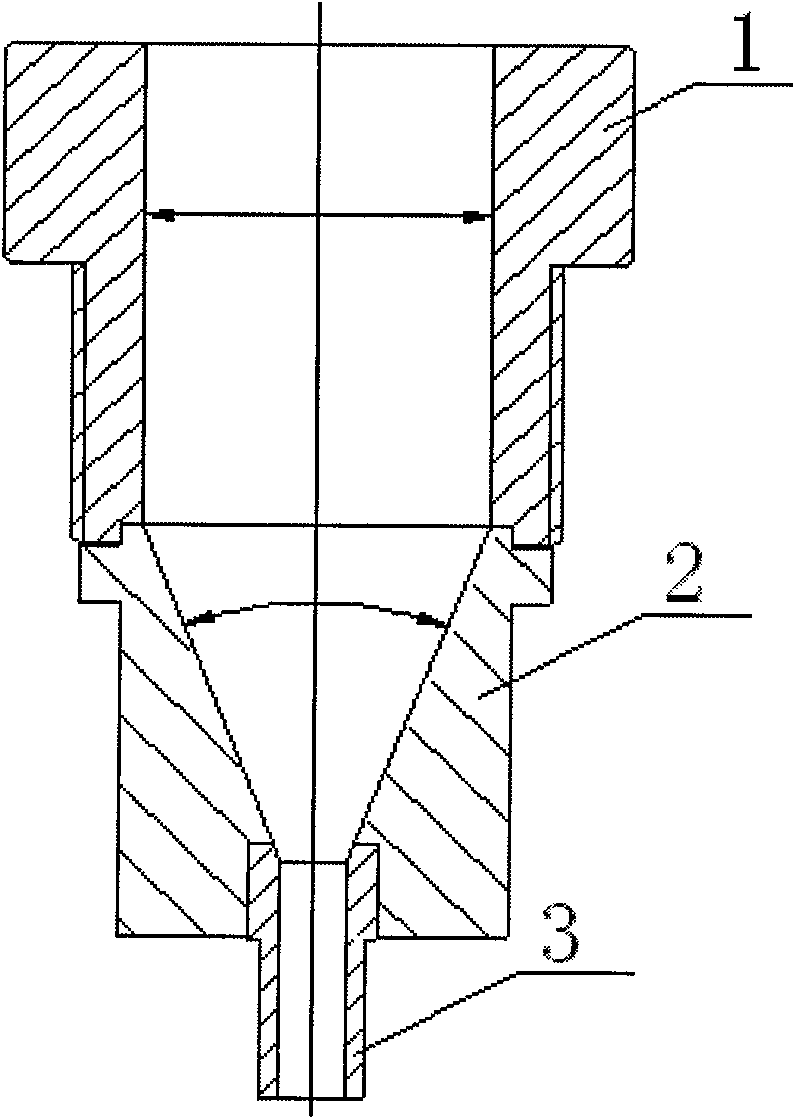

Image

Examples

Embodiment 1

[0039] The manufacturing method of polytetrafluoroethylene colored raw material tape for winding and sintering, its manufacturing steps are as follows:

[0040] (1) Put the polytetrafluoroethylene dispersed resin in a freezer to refrigerate at a temperature of 15° C. for 24 hours, and then sieve through an 8-mesh sieving machine.

[0041] (2) Mix the sieved polytetrafluoroethylene dispersion resin with the propellant, and let it stand for 2 hours; then stir for 14 minutes, and the mixing temperature is not higher than 19°C; let it stand for 24 hours; the polytetrafluoroethylene dispersion The parts by weight of the resin and the booster consist of: polytetrafluoroethylene dispersion resin is 70-85%, and the booster is 15-25%; the booster can be one of kerosene solvent oil, sherwood oil or paraffin oil. species or a mixture of species.

[0042] (3) Carry out aging treatment; the aging treatment is carried out in the aging box, the aging temperature is 50-60° C., and the aging ...

Embodiment 2

[0049] The manufacturing method of polytetrafluoroethylene colored raw material tape for winding and sintering, its manufacturing steps are as follows:

[0050] (1) Put the polytetrafluoroethylene dispersed resin in a freezer to refrigerate at a temperature of 15° C. for 24 hours, and then sieve through an 8-mesh sieving machine.

[0051] (2) Mix the sieved polytetrafluoroethylene dispersion resin with the propellant, and let it stand for 3 hours; then stir for 15 minutes, and the mixing temperature is not higher than 19°C; let it stand for 24 hours; the polytetrafluoroethylene dispersion The parts by weight of the resin and the booster are as follows: 80% polytetrafluoroethylene dispersion resin and 20% booster; the booster can be one or more of kerosene solvent oil, petroleum ether or paraffin oil.

[0052] (3) Carry out aging treatment; the aging treatment is carried out in the aging box, the aging temperature is 50-60° C., and the aging time is 24 hours.

[0053] (4) Pref...

Embodiment 3

[0059] The manufacturing method of polytetrafluoroethylene colored raw material tape for winding and sintering, its manufacturing steps are as follows:

[0060] (1), the polytetrafluoroethylene dispersion resin is refrigerated, and then sieved. The polytetrafluoroethylene dispersed resin can be placed in a freezer for refrigeration at a temperature of 10-19° C. for 20-30 hours, and the sieving can be carried out by sieving through an 8-10 mesh sieving machine.

[0061] (2) Add pigments accounting for 5% by weight of the polytetrafluoroethylene dispersion resin to the sieved polytetrafluoroethylene dispersion resin, and then stir for 10 to 20 minutes.

[0062] (3), the sieved polytetrafluoroethylene dispersion resin and propellant are mixed, stand still; The weight part of polytetrafluoroethylene dispersion resin and propellant is made up of: polytetrafluoroethylene dispersion resin is 60~90 %, the booster is 10-30%. The booster can be one or a mixture of kerosene, solvent na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com