Spraying method and spraying equipment for two-component coating

A two-component coating and spraying equipment technology, which is applied to the surface coating liquid device, coating, spraying device, etc., can solve the problems of long time and limited coating thickness, and achieve firm combination, energy saving and Cost, the effect of high puncture resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

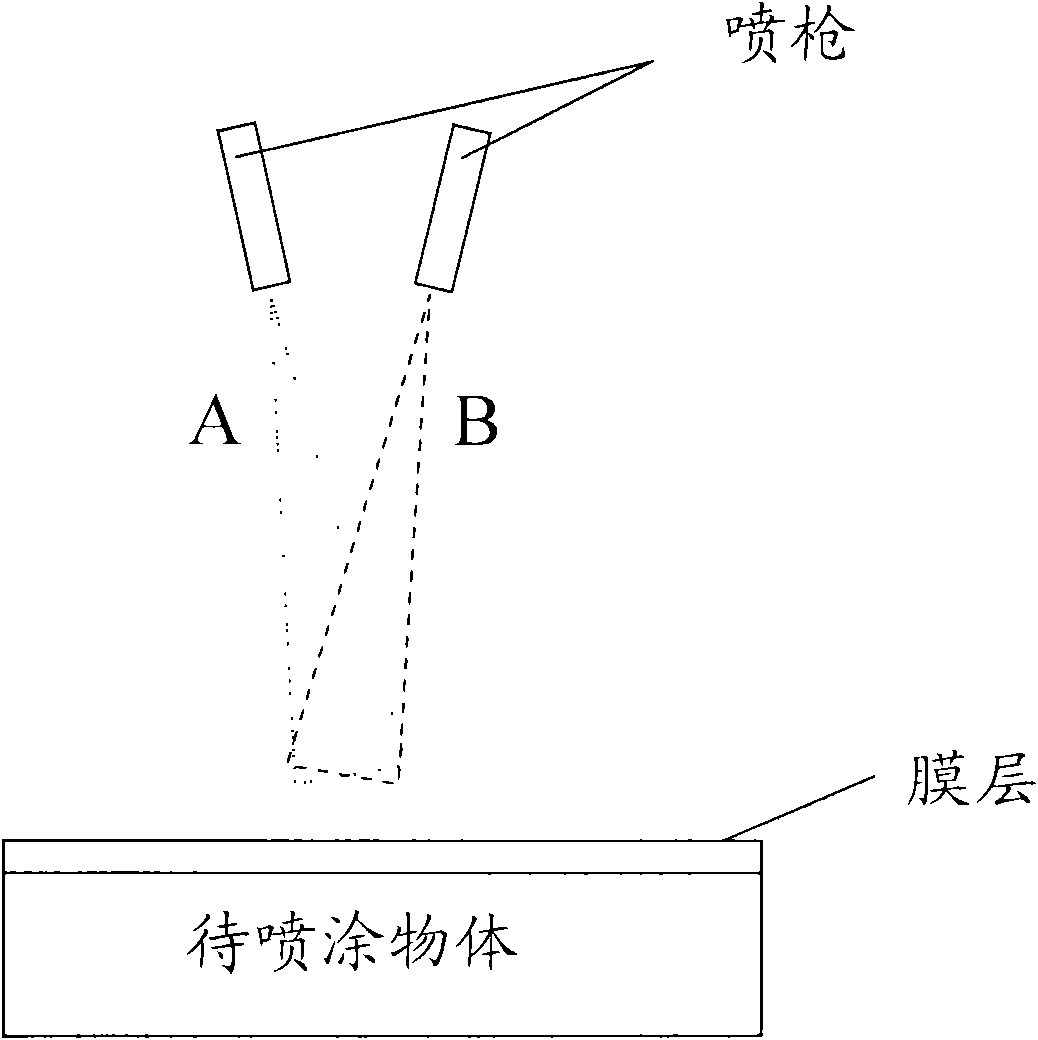

[0019] The spraying method according to the invention comprises firstly preparing the first component A and the second component B of the paint. The first component A includes superfine suspension microemulsion type modified emulsified asphalt. Asphalt materials are insoluble in water and do not mix with water, but through high-speed agitation or shearing, the asphalt is broken into tiny particles and dispersed in an aqueous solution of surface active substances with emulsifiers to obtain a uniformly dispersed colloid. The basic function of emulsifiers is to reduce surface tension. It is characterized by a water-soluble (hydrophilic) polar group and an oil-soluble (hydrophobic) non-polar group in the molecule. In the asphalt-water system, the emulsifier molecules move between the asphalt and the water interface, and the hydrophobic groups of the molecules are adsorbed on the surface of the asphalt and charged, while the hydrophilic groups enter the water phase. This links th...

no. 2 example

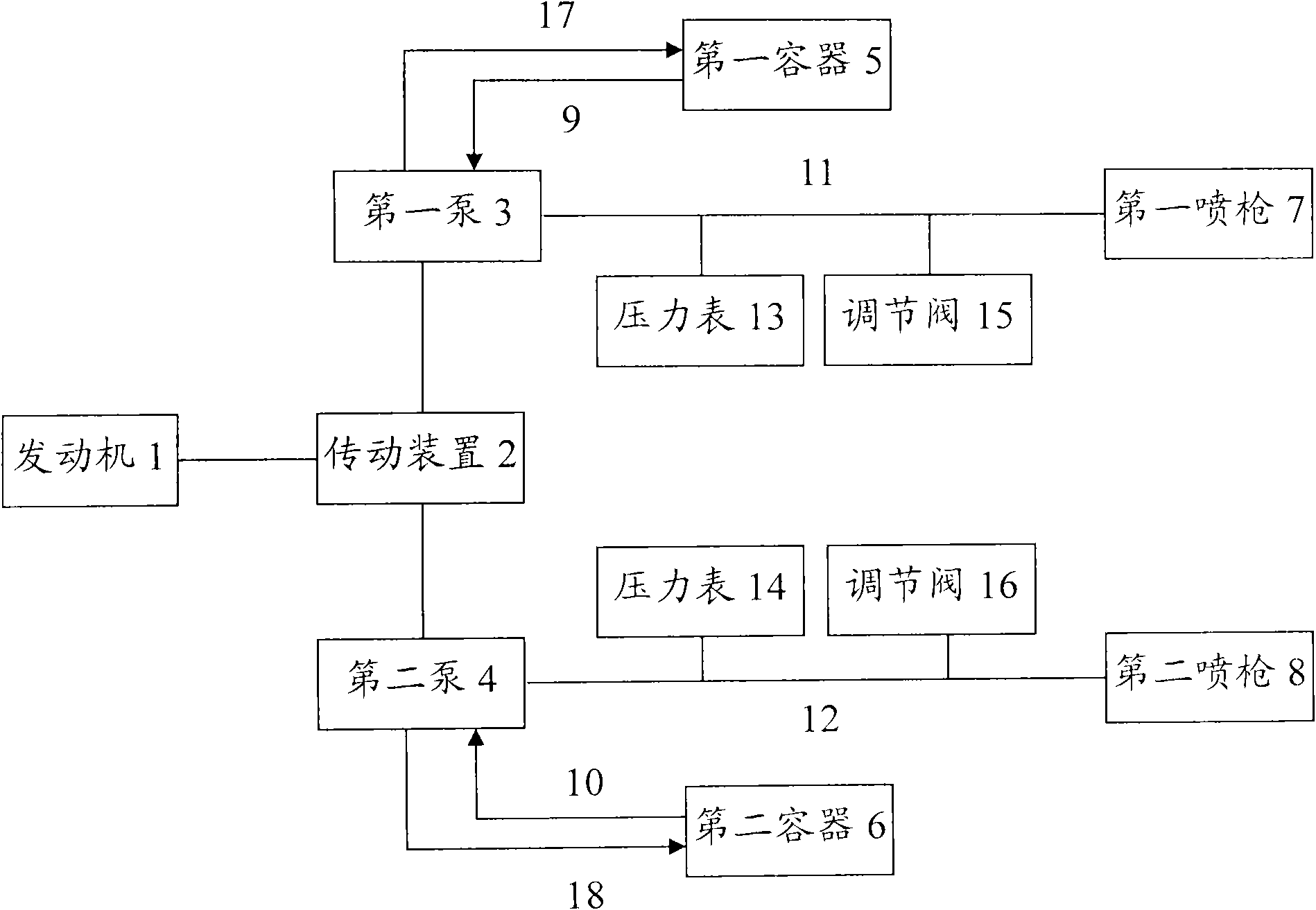

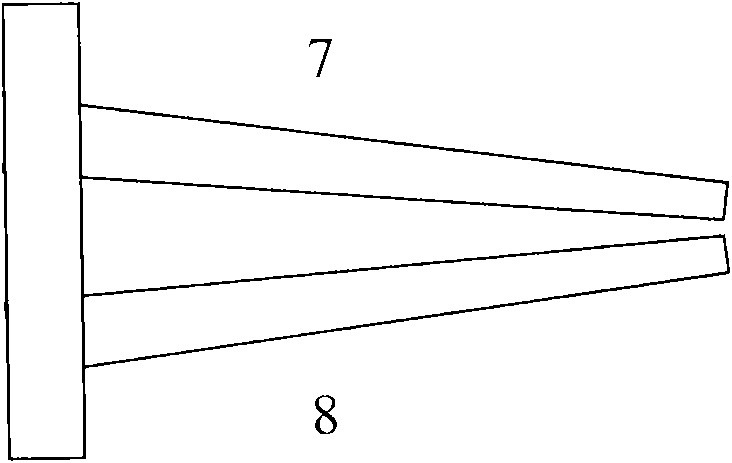

[0025] figure 2 It is a structural schematic diagram of the spraying equipment according to the second embodiment of the present invention. The spraying equipment includes an engine 1 , a transmission 2 , a first pump 3 , a second pump 4 , a first container 5 , a second container 6 , a first spray gun 7 and a second spray gun 8 . The engine 1 can be a gasoline engine, a diesel engine or an electric motor to generate power to drive the first pump 3 and the second pump 4 . The transmission device 2 transmits the power of the engine 1 to the first pump 3 and the second pump 4 respectively. The transmission device 2 can adopt various transmission modes. For example, the transmission device 2 can be composed of a power output device on the engine 1 such as a driving wheel, a power input device of the first pump 3 and the second pump 4 such as a driven wheel, and two belts connecting the driving wheel and the two driven wheels respectively . The transmission device 2 can also a...

no. 3 example

[0031] Figure 4 It is a structural schematic diagram of the spraying equipment according to the third embodiment of the present invention. The difference between the spraying equipment of the third embodiment and the second embodiment is that, in addition to being connected with the first spray gun 7 and the second spray gun 8, the first pump 3 and the second pump 4 are also connected with the third spray gun 19 and the fourth spray gun. Spray guns 20 are connected. That is, the first pump 3 and the second pump 4 are respectively connected with two spray guns. Similar to the first spray gun 7 and the second spray gun 8, the third spray gun 19 and the fourth spray gun 20 can also be fixed on a base with a predetermined angle formed therebetween. Since the number of spray guns of the spraying equipment according to the third embodiment of the present invention is increased, the efficiency of the spraying equipment is increased. According to specific conditions, the spraying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com