Propylene resin composition, method for producing propylene resin composition, propylene polymer composition, molded body made of the propylene resin composition, and electric wire

一种丙烯类树脂、组合物的技术,应用在塑料/树脂/蜡绝缘体、导体、电路等方向,能够解决耐损伤性不充分、不表现柔韧性、柔韧性困难等问题,达到应力吸收性优异、阻燃性优异、低温特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0427] Using a Labo Plastomill manufactured by Toyo Seiki Seisakusho Co., Ltd., the composition composed of the formulations in Table 4 was kneaded, and molded into a sheet with a thickness of 2 mm by a pressure molding machine (heating: 190° C. × 7 min, Cooling: 15°C×4min, cooling rate: -40°C / min). This sheet was evaluated for the aforementioned mechanical properties, hardness, heat resistance, scratch resistance, and stress absorbability. The results are shown in Table 4.

[0428] [Examples 2 to 10, Reference Example 1, Comparative Example 1]

[0429] Molding and evaluation were carried out in the same manner as in Example 1, except for changing to a composition composed of the formulations in Table 3. The results are shown in Table 4.

[0430]

[0431] The propylene-based resin composition (Examples 1 to 10) of the present invention has good heat resistance and excellent damage resistance and stress absorption properties compared with the ethylene-based resin compositio...

Embodiment 11~14

[0432] [Examples 11 to 14, Comparative Example 11]

[0433] Using a Labo Plastomill manufactured by Toyo Seiki Seisakusho Co., Ltd., the composition composed of the formulations in Table 5 was kneaded, and molded into a sheet with a thickness of 2 mm by a pressure molding machine (heating: 190° C. × 7 min. Cooling: 15°C×4min, cooling rate: -40°C / min). The above-mentioned mechanical properties, hardness, low-temperature properties, and abrasion resistance were evaluated for this sheet. The results are shown in Table 5.

[0434]

[0435] Compared with Comparative Example 11, the propylene-based resin composition (Examples 11 to 14) of the present invention has particularly excellent elongation at break (EL) and abrasion resistance.

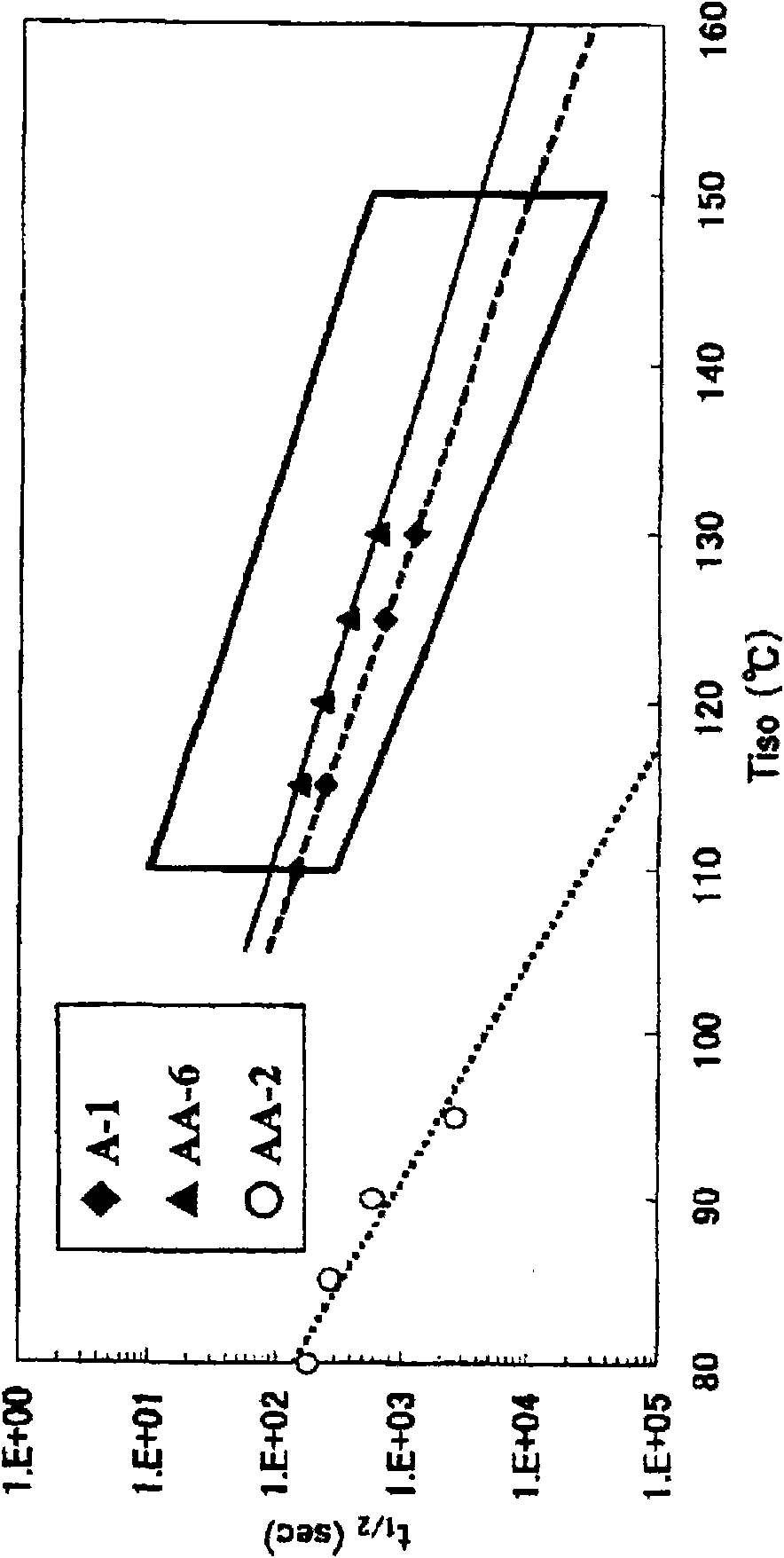

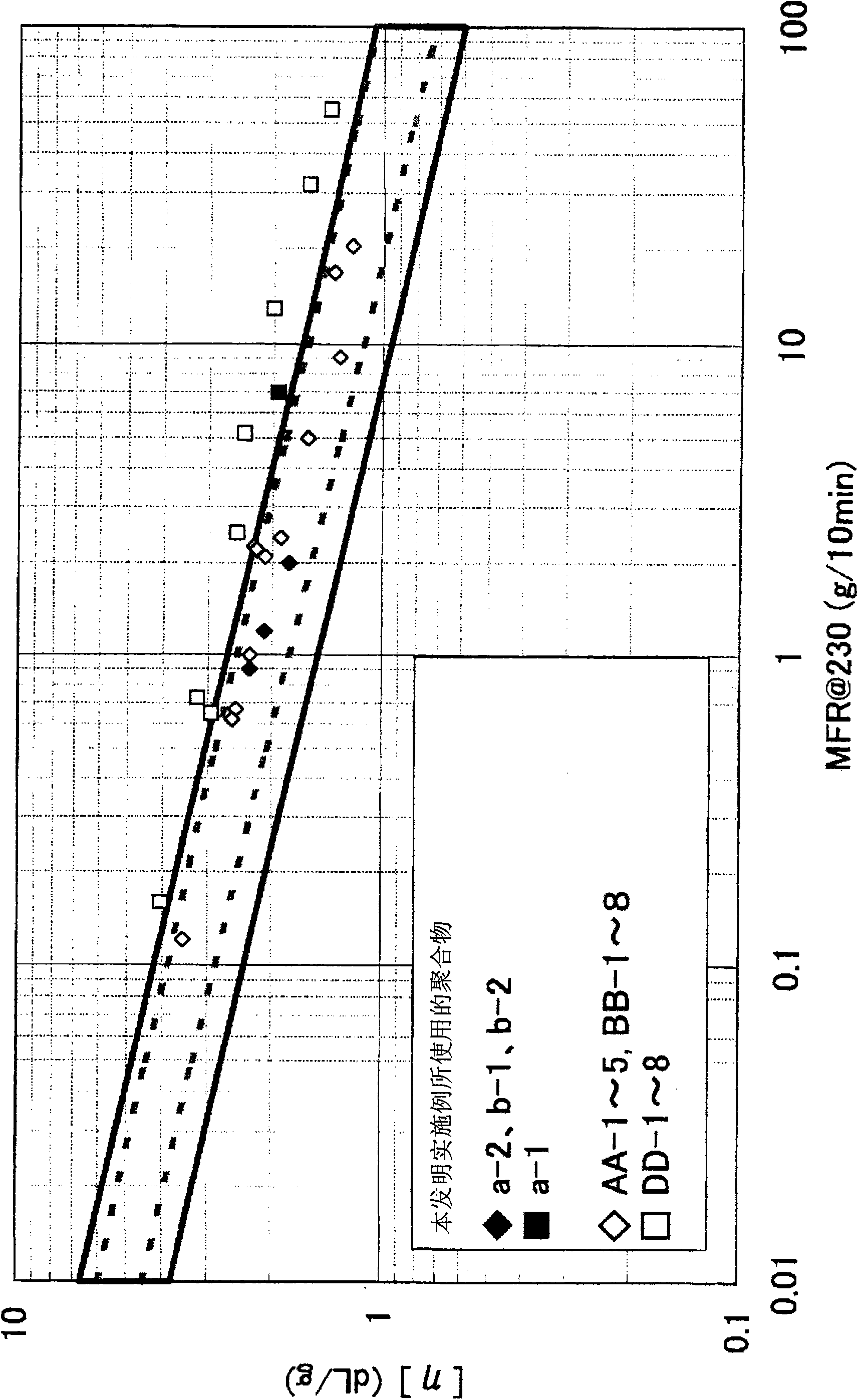

[0436] In addition, in figure 2 represents the above iPP (a-1), sPP (a-2), PBER (b-1) and PER (b-2), and the following polymers (AA-1) to (AA-5), (BB Relationship between MFR and [η] of -1) to (BB-8) and isotactic polymers (DD-1) to (DD-8). ...

Synthetic example 1

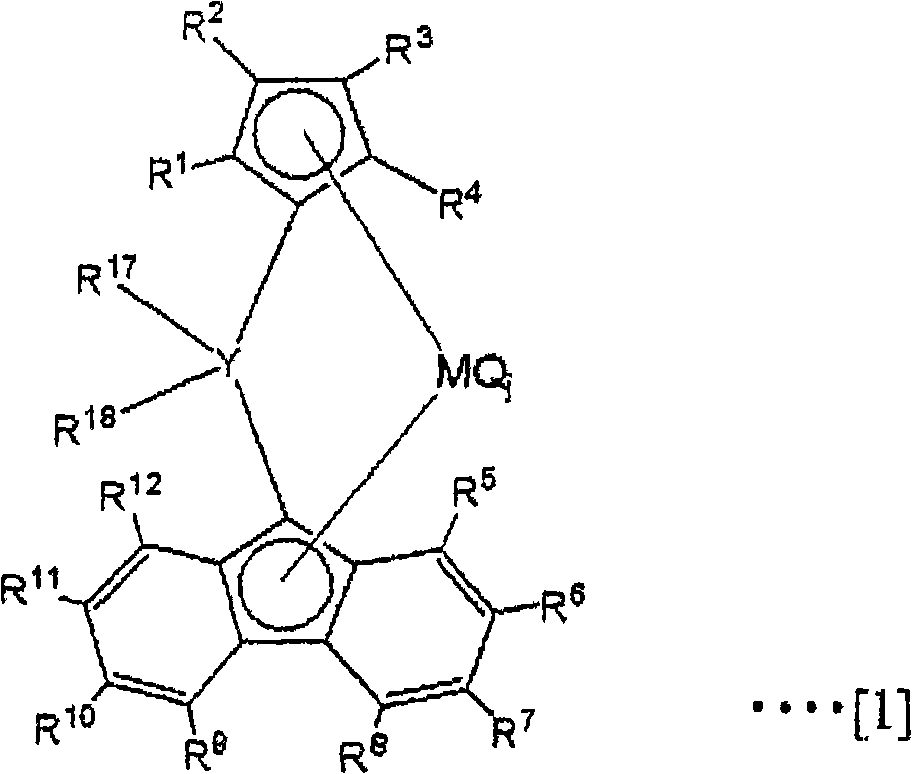

[0438] Diphenylmethylene (3-tert-butyl-5-ethylcyclopentadienyl) (2,7-di-tert-butylfluorenyl) di Synthesis of Zirconium Chloride

[0439] (i) Synthesis of 1-ethyl-3-tert-butylcyclopentadiene

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com