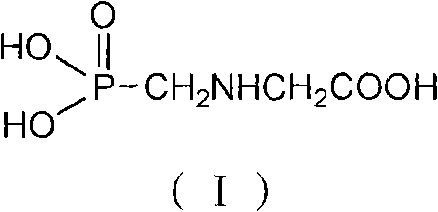

Novel process for preparing glyphosate by glycin method

A technology of glycine and glyphosate, applied in herbicides and algicides, chemical instruments and methods, chemicals for biological control, etc., to achieve the effects of reducing pollution, reducing loss, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

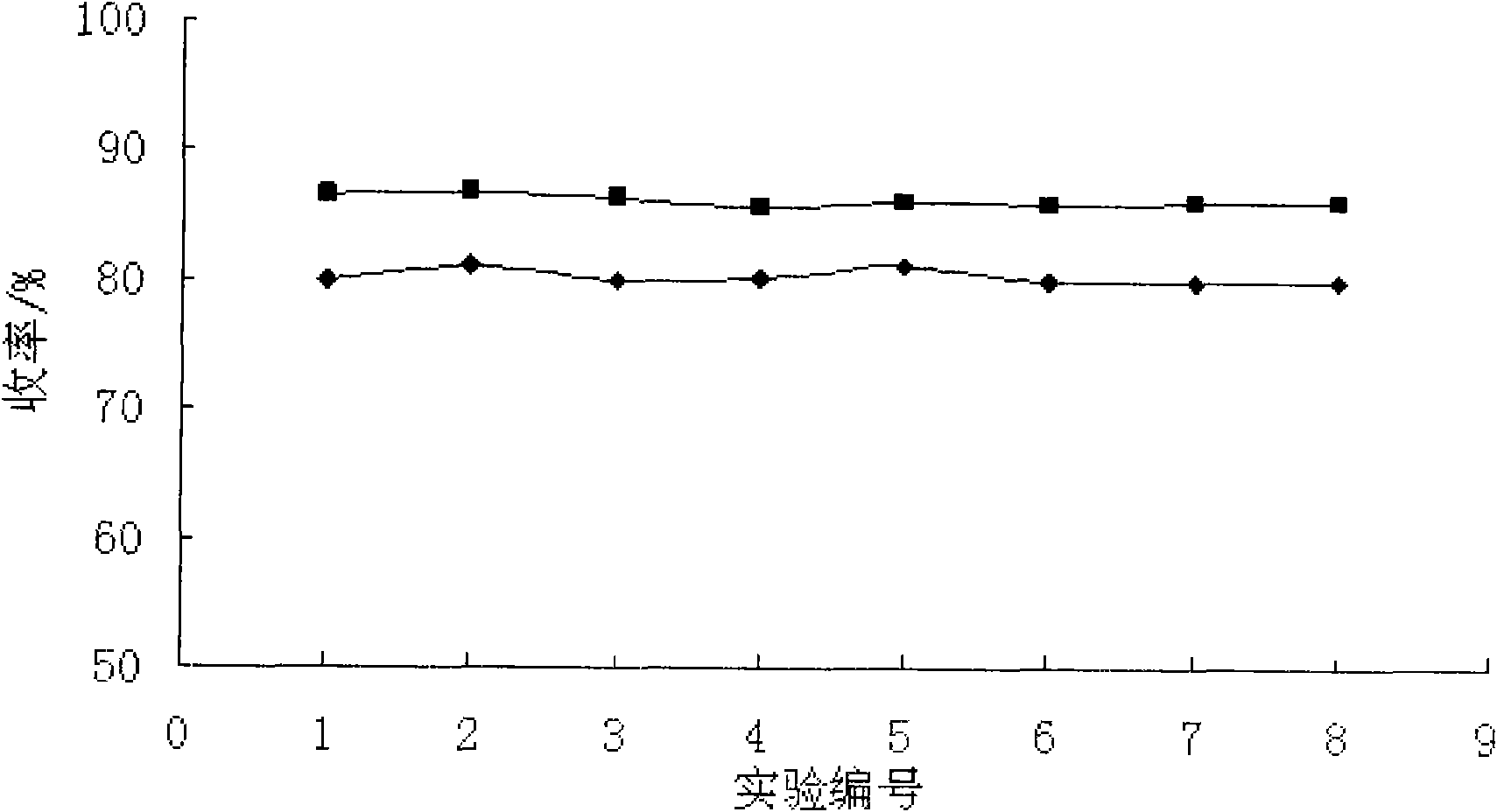

Examples

Embodiment 1

[0033]15.63g (0.5mol) of paraformaldehyde, 25.6g (0.253mol) of triethylamine, 19g (0.25mol) of glycine and 120ml of methanol were simultaneously placed in a 500mL four-necked flask with a reflux condenser, a thermometer and stirring, and stirred until After becoming transparent, the temperature was raised to 45°C, 30.90 g (0.30 mol) of dimethyl phosphite was added, and the reaction was maintained at 45-65°C until the reaction was completed. 45-70°C blow air analysis to recover methanol and triethylamine, after no obvious liquid outflow, naturally cool down to about 40°C, slowly add hydrochloric acid (30%) 38.00g (0.313mol) dropwise, keep warm at 50-75°C until reaction Completely, at the same time blow air to analyze and remove formaldehyde until the end of acidolysis, then deacidify under reduced pressure, stop the reduced pressure when the temperature reaches 110°C, add 40.00g of water, cool and crystallize, filter and dry to obtain 34.78g of glyphosate raw powder (content 97...

Embodiment 2

[0035] 11.72g (0.375mol) of paraformaldehyde, 25.6g (0.253mol) of triethylamine, 19g (0.25mol) of glycine and 120ml of methanol were simultaneously placed in a 500mL four-necked flask with a reflux condenser, a thermometer and stirring, and stirred until After becoming transparent, the temperature was raised to 45°C, 29.66g (0.288mol) of dimethyl phosphite was added, and the reaction was maintained at 45-65°C until the reaction was completed. Distill at 90-110°C under atmospheric pressure to separate and recover methanol and triethylamine. After no obvious liquid flows out, cool down naturally to about 40°C. Slowly add 38.00g (0.313mol) of hydrochloric acid (30%), and keep warm for acidolysis at 50-75°C until The reaction is complete, and at the same time blow air to analyze and remove formaldehyde until the end of acidolysis, deacidify under reduced pressure at the reaction temperature, add 20.00g of water, then use NaOH (30%) to adjust the pH to about 1.5, filter and dry to o...

Embodiment 3

[0037] 14.47g (0.463mol) of paraformaldehyde, 25.6g (0.253mol) of triethylamine, 19g (0.25mol) of glycine and 120ml of methanol were simultaneously placed in a 500mL four-necked flask with a reflux condenser, a thermometer and stirring, and stirred until After becoming transparent, the temperature was raised to 45°C, 25.75g (0.25mol) of dimethyl phosphite was added, and the reaction was maintained at 45-65°C until the reaction was completed. Recover methanol and triethylamine by distillation under reduced pressure at 40-70°C. After no obvious liquid flows out, the temperature is naturally lowered to about 40°C, and 51.71g (0.425mol) of hydrochloric acid (30%) is slowly added dropwise, and the pressure is reduced at 50-75°C (P = -0.01 to -0.03MPa) acidolysis until the reaction is complete, then adjust the pH to about 1.5 with NaOH (30%), filter and dry to obtain 34.02g (content 97%) of glyphosate former powder, the former powder yield 80.5%, The total yield is 85.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com