Ethylene unit alkaline washing tower polymer inhibitor and preparation method and application thereof

A technology for ethylene devices and inhibitors, applied in the fields of hydrocarbons, chemical instruments and methods, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-14

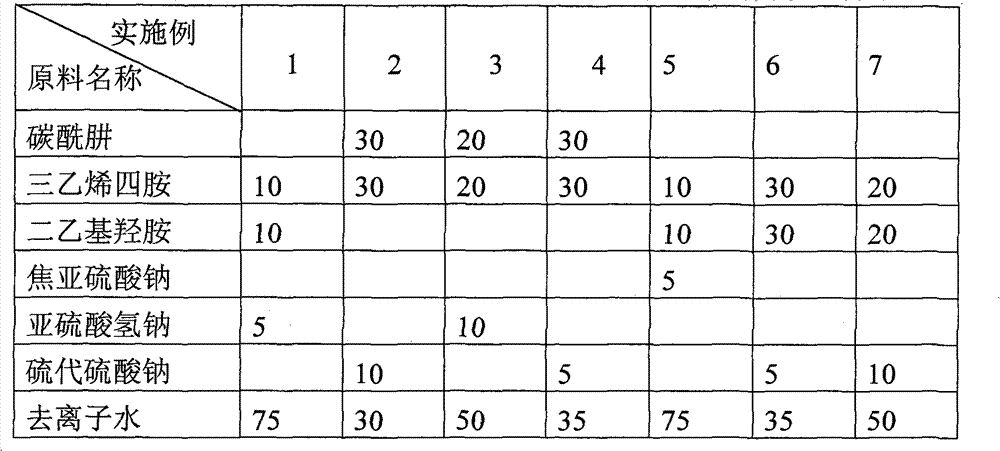

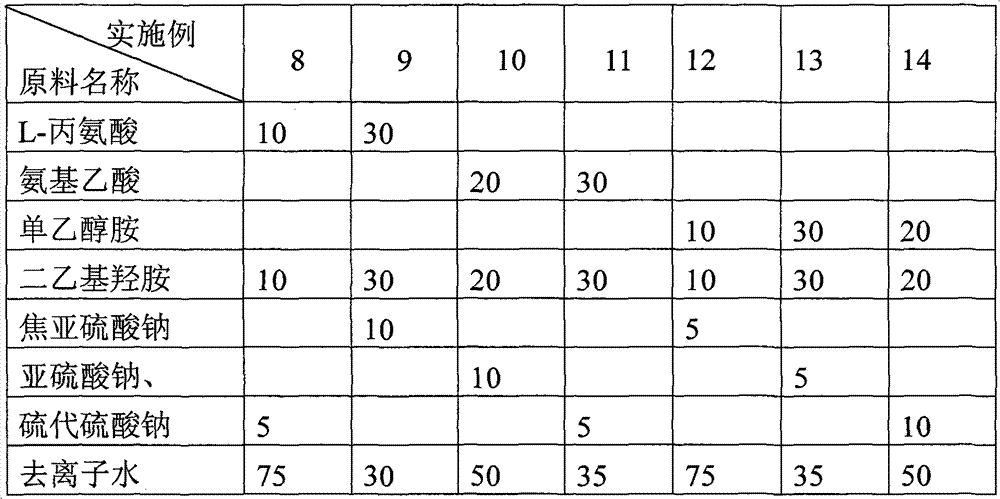

[0028] Examples 1-14 are examples of the components, proportioning and preparation of the polymer inhibitor.

[0029] Under normal temperature, normal pressure, and constant stirring, respectively add certain parts by mass of the compounds in Table 1 and Table 2 into deionized water of corresponding parts by mass until each component is completely dissolved, that is, the ethylene device of the present invention is obtained. Alkaline scrubber polymer inhibitor. Among them, the conductivity of deionized water is less than 10μs·cm -1 .

[0030] Table 1 embodiment 1-7 polymer inhibitor component and proportioning (data in the table are all mass fractions)

[0031]

[0032] Table 2 embodiment 8-14 polymer inhibitor component and proportioning (data in the table are all mass fractions)

[0033]

Embodiment 15

[0035] The alkali washing tower polymer inhibitor in the embodiment 2 is applied to the alkali washing tower of the ethylene simulation device, the cracking raw material is naphtha, and the total yield of ethylene, propylene and butadiene in the cracking gas is 43.2%, and in the alkali washing tower The concentration of sodium hydroxide is 8%, and the inhibitor is added to the circulating lye at one time. The filling amount is 50 μg / g relative to the amount of cracked gas. The device runs for 2 hours, and the amount of polymer in the lye is measured. Blank experiments were reduced by 50%.

Embodiment 16

[0037] The alkali-washing tower polymer inhibitor in embodiment 6 is applied to the alkali-washing tower of the ethylene simulation device, and the cracking raw material is naphtha, and the total yield of ethylene, propylene, and butadiene in the cracking gas is 43.2%, and in the alkali-washing tower The concentration of sodium hydroxide is 8%, the inhibitor is added to the circulating lye at one time, the injection amount is 50 μg / g relative to the amount of cracked gas, the device is operated for 2 hours, and the amount of polymer in the lye is measured, the amount of polymer is relative to the blank experiment 56% reduction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com