Zirconia reinforced silicon nitride/quartz-matrix ceramic composite material and preparation method thereof

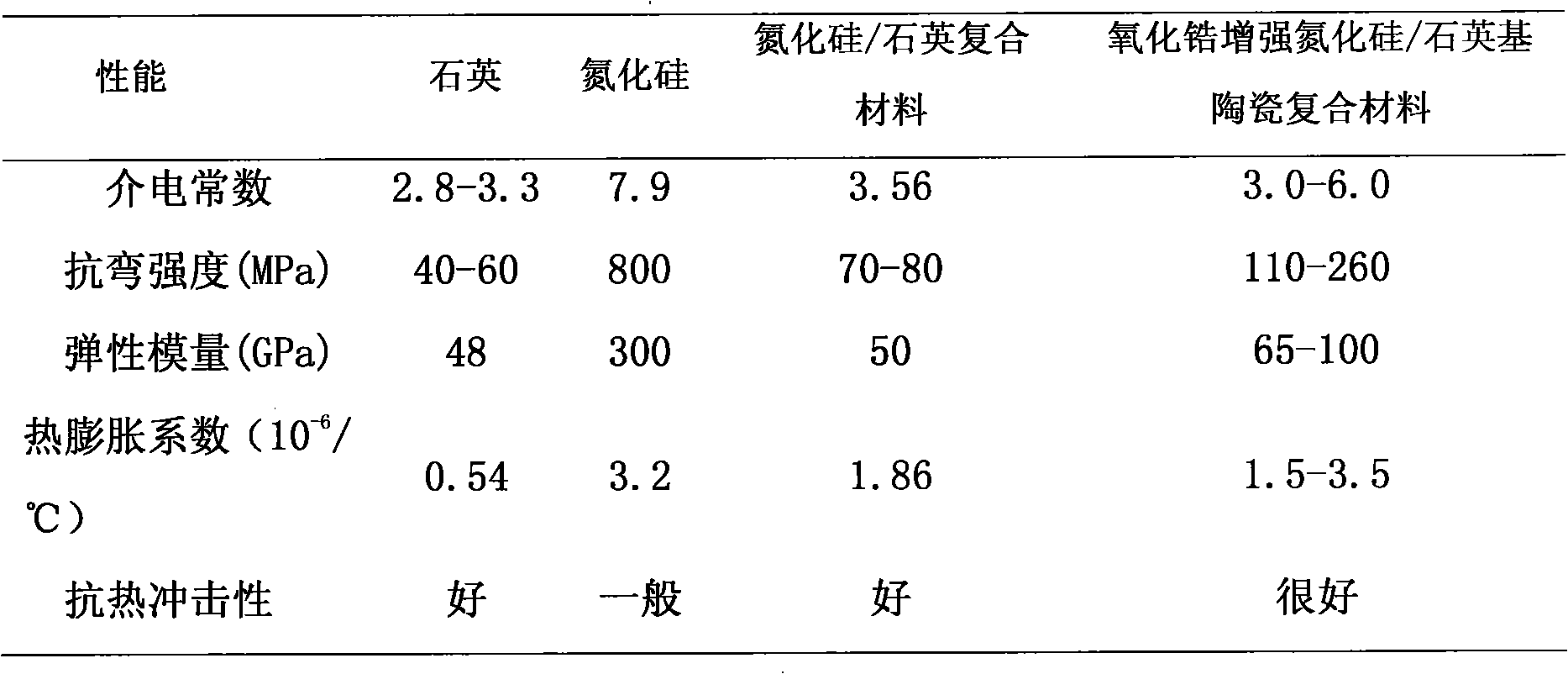

A technology of ceramic composite materials and silicon nitride, which is applied in the field of special ceramics, can solve the problems of poor dielectric and thermal shock resistance, low strength, etc., achieve good ablation resistance, meet application requirements, and be easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

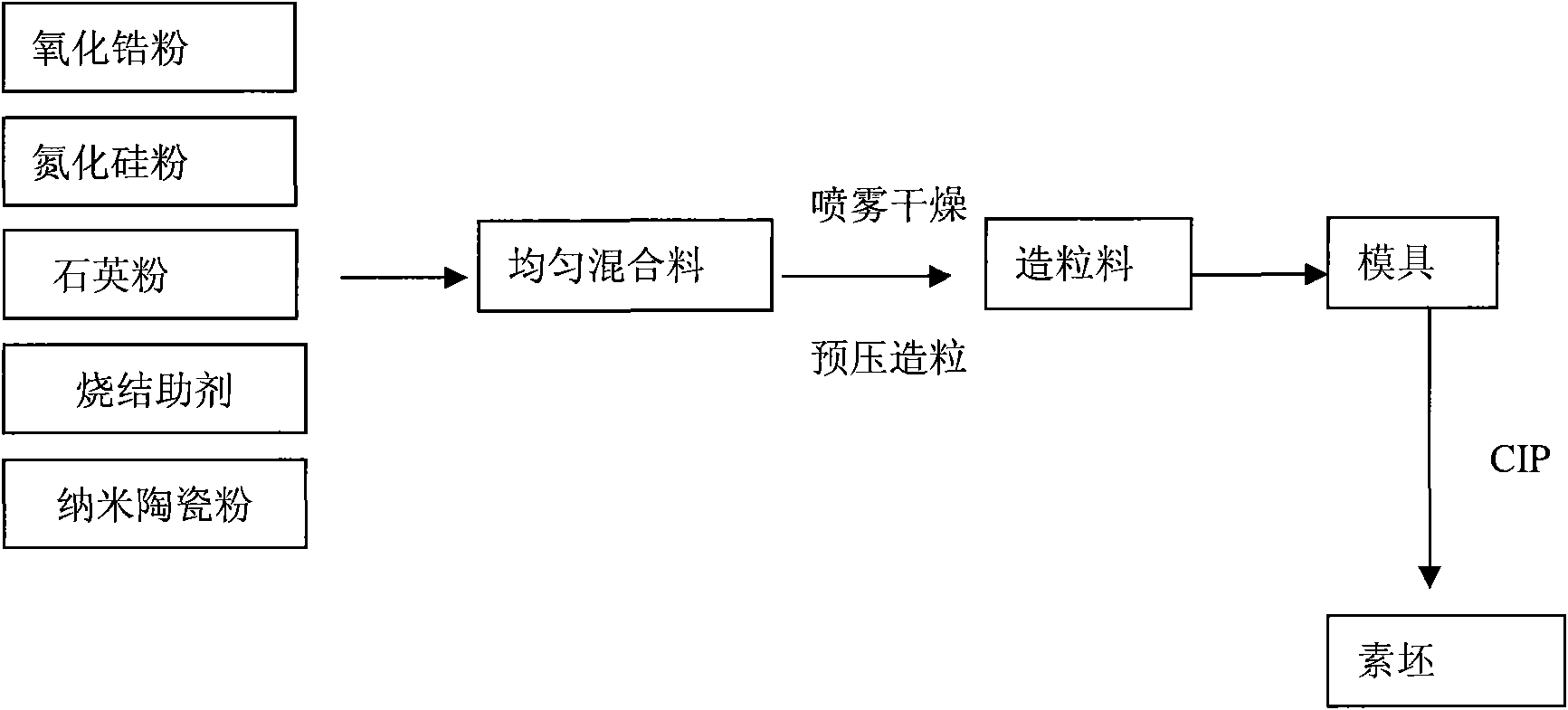

Method used

Image

Examples

Embodiment 1

[0037] Raw materials used:

[0038] α-Si in silicon nitride powder 3 N 4 The weight content is 95%, f si 50 0.6μm;

[0039] In quartz powder, SiO 2 The weight content is 99%, amorphous, median particle size D 50 = 4.7 μm;

[0040] Nano ceramic powder is nano SiO 2 , amorphous, SiO 2 The weight content is 99%;

[0041] Zirconia powder, analytically pure, ZrO 2 The weight content is 99.1%, and the median particle size is 0.8μm;

[0042] Sintering aid is Y 2 o 3 , analytically pure, with a median particle size of 1.1 μm.

[0043] Weigh 130g of quartz powder, 54g of silicon nitride powder, 6g of sintering aid, 10g of nano-ceramic powder, 30g of zirconia powder, use deionized water as a dispersant, mix by ball milling, pass through a 180-mesh sieve, and pass through a centrifugal drying granulator Granules with a particle size of 100-500μm, and then evenly loaded into a special oil-resistant rubber mold, and molded in a wet cold isostatic press with a molding pressure ...

Embodiment 2

[0045] Raw materials used:

[0046] α-Si in silicon nitride powder 3 N 4 The weight content is 96%, f si 50 0.7μm;

[0047] In quartz powder, SiO 2 The weight content is 99%, amorphous, median particle size D 50 = 10 μm;

[0048] Nano ceramic powder is nano SiO 2 , amorphous, SiO 2 The weight content is 99.6%;

[0049] Zirconia powder, analytically pure, ZrO 2 The weight content is 99.5%, and the median particle size is 1 μm;

[0050] Sintering aid is Al 2 o 3 , analytically pure, with a median particle size of 0.9 μm.

[0051]Weigh 130g of quartz powder, 54g of silicon nitride powder, 6g of sintering aid, 10g of nano-ceramic powder, 20g of zirconia powder, use deionized water as a dispersant, mix by ball milling, pass through a 180-mesh sieve, and pass through a centrifugal drying granulator Granules with a particle size of 100-500μm, and then evenly loaded into a special oil-resistant rubber mold, and molded in a wet cold isostatic press with a molding pressure ...

Embodiment 3

[0053] Raw materials used:

[0054] α-Si in silicon nitride powder 3 N 4 The weight content of 93%, f si 50 0.6μm;

[0055] In quartz powder, SiO 2 The weight content is 99%, amorphous, median particle size D 50 = 6 μm;

[0056] Nano ceramic powder is nano SiO 2 , amorphous, SiO 2 99.1% by weight;

[0057] Zirconia powder, analytically pure, ZrO 2 The weight content is 99.1%, and the median particle size is 1 μm;

[0058] Sintering aid is Y 2 o 3 , analytically pure, with a median particle size of 1.3 μm.

[0059] Weigh 130g of quartz powder, 54g of silicon nitride powder, 6g of sintering aid, 10g of nano-ceramic powder, 20g of zirconia powder, use deionized water as a dispersant, mix with a ball mill, pass through a 180-mesh sieve, dry, and press to produce a particle size 100-500μm, and then uniformly loaded into a special oil-resistant rubber mold, and molded in a wet cold isostatic press with a molding pressure of 150MPa. The formed test pieces were fired in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com