Method for manufacturing rigid carbon fiber heat insulating material and surface treatment method

A technology of thermal insulation and manufacturing method, which is applied in the field of rigid carbon fiber thermal insulation materials and manufacturing, can solve the problems of low strength, increased thermal conductivity, short service life, etc., and achieves simple process, high stability and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0054] Isotropic pitch-based carbon fiber P-800 is used, the value represents the fiber length in microns, and P represents the ground product. Grind the mixture of carbon fiber and sucrose solution with concentrations of 30% and 50%, respectively, and add 0.8% carboxymethylcellulose dispersant. After the aspirator is formed to meet the thickness requirements, lift the aspirator out of the water and continue to suck for 30-150s. Specific steps are as follows:

[0055] (1) Isotropic pitch-based fibers were pulverized or ground to obtain short fibers with an average length of 800 μm.

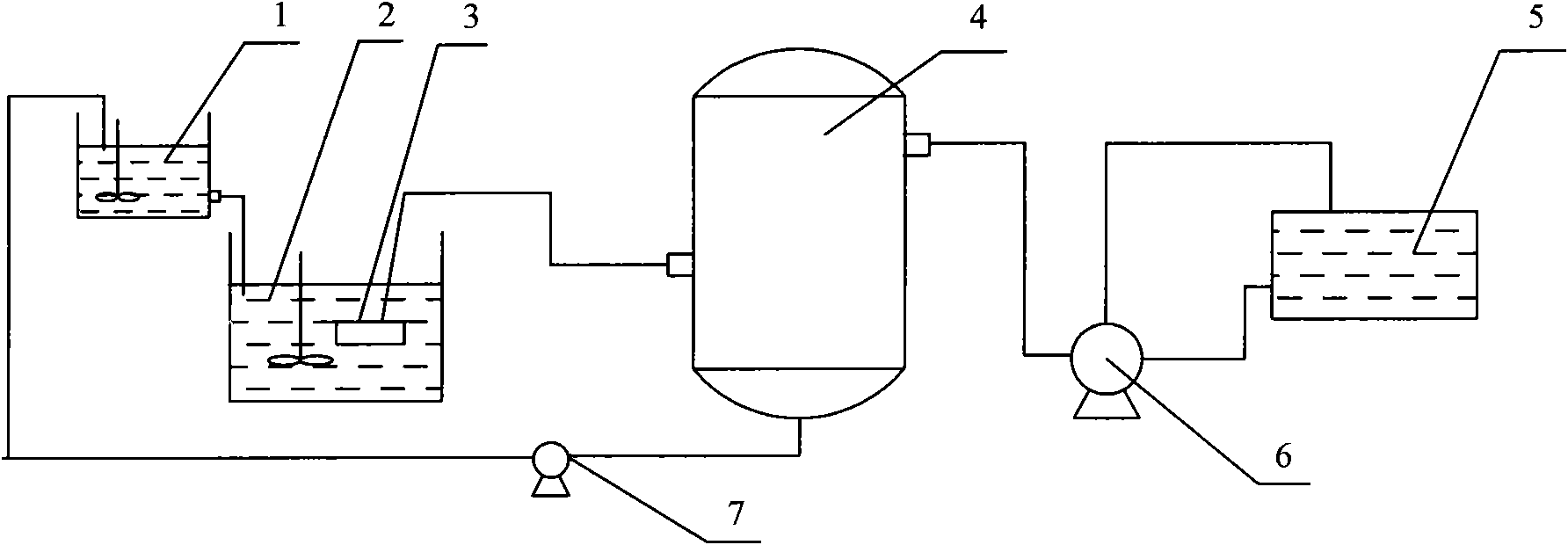

[0056] (2) if figure 1 As shown, the binder and carbon fiber are mixed in the mixing tank 1, and the weight percentages of the binder solution are 30% and 50% respectively.

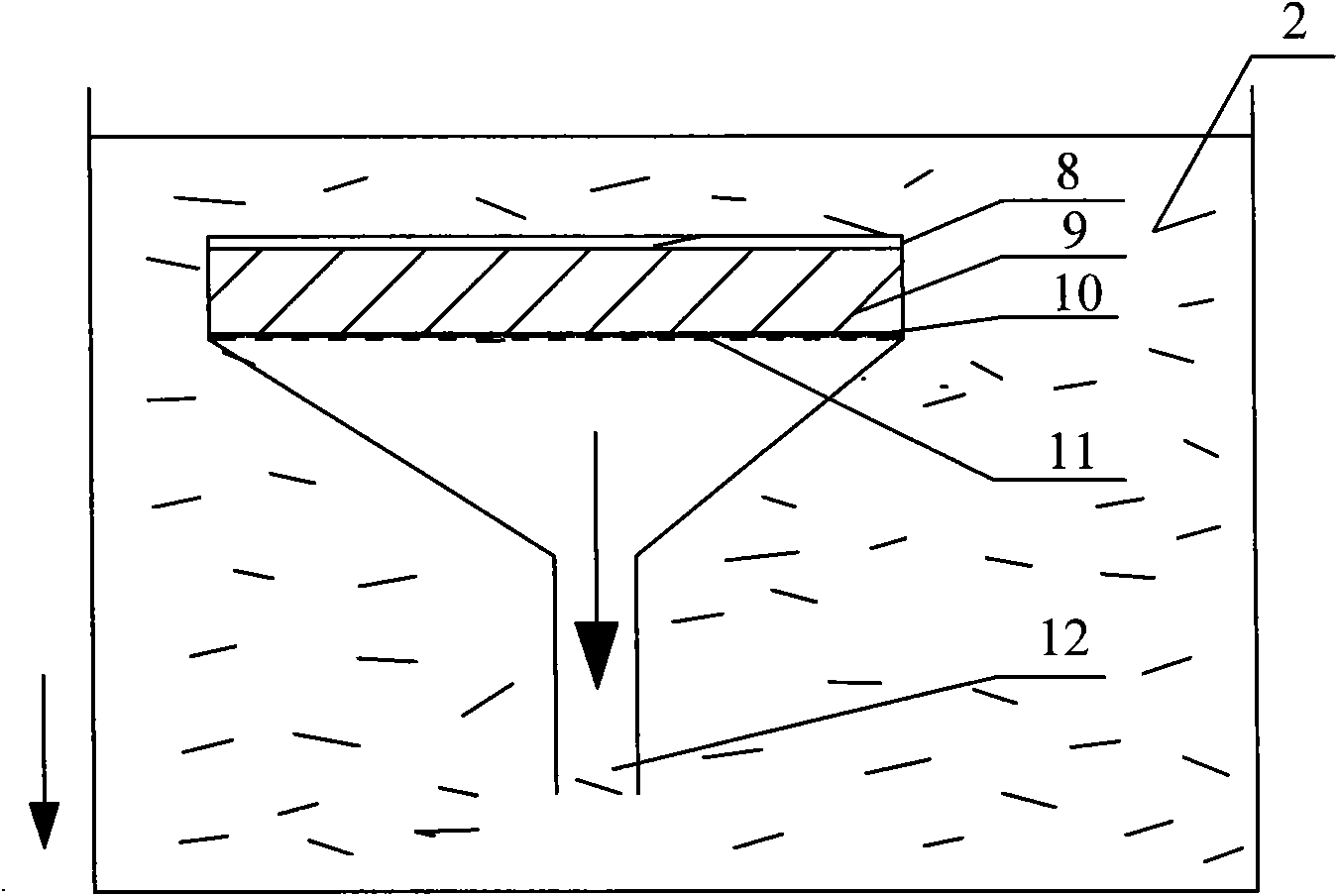

[0057] (3) if figure 1 , 2 As shown, the mixture of binder and carbon fiber is put into the molding tank 2 with the aspirator 3, and the aspirator 3 is used for suction molding for about 1 to 10 minutes. Adhesive and ca...

example 2

[0064] (1) Isotropic pitch-based carbon fiber P-800 is used, the value represents the fiber length in microns, and P represents the ground product. The mixture of carbon fiber and 30% sucrose solution is formed by the aspirator. After reaching the thickness requirement, lift the aspirator out of the water and continue to suck for 30-50s. The specific molding and carbonization steps are the same as Example 1, and the filming steps are as follows:

[0065] Carry out surface polishing treatment to the carbonized rigid heat insulating material 15 to make the surface smooth.

[0066] (2) The weight ratio of each component of the binder is phenolic resin: boron carbide = 100:100, and the high temperature binder can be obtained by mixing the phenolic resin and boron carbide evenly according to the above ratio.

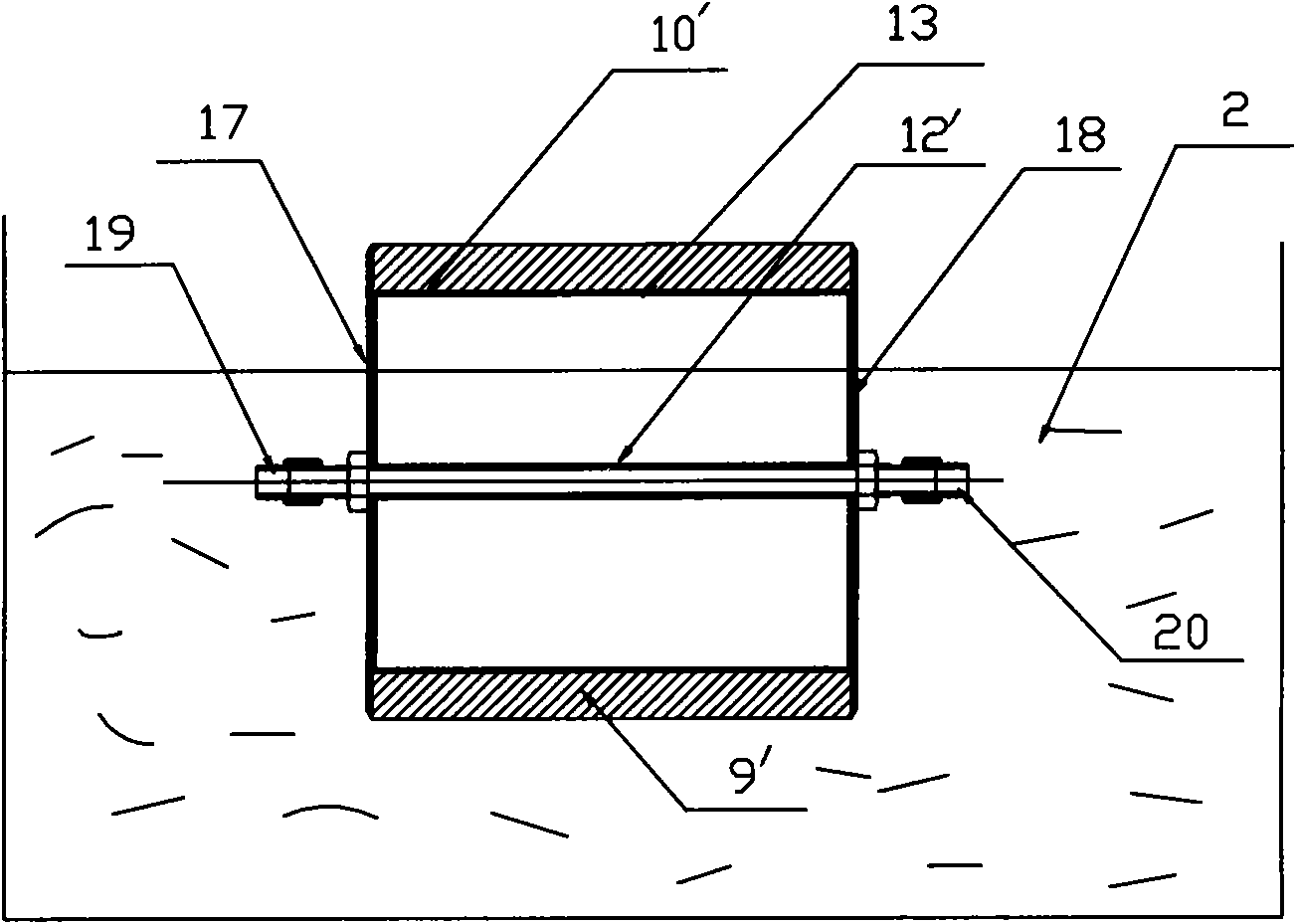

[0067] (3) if Figure 4 As shown, a layer of high-temperature adhesive layer 16 is coated on the upper surface of the rigid thermal insulation material 15, and then graphit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com