Precision static pressure linear guide rail

A linear guide, static pressure technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of power consumption, oil guide wear, affecting the accuracy of the machine tool, etc., to eliminate the heating phenomenon, the driving power is small , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are exemplified, and the precision static pressure linear guide rail of the present invention is described in detail with reference to the accompanying drawings as follows:

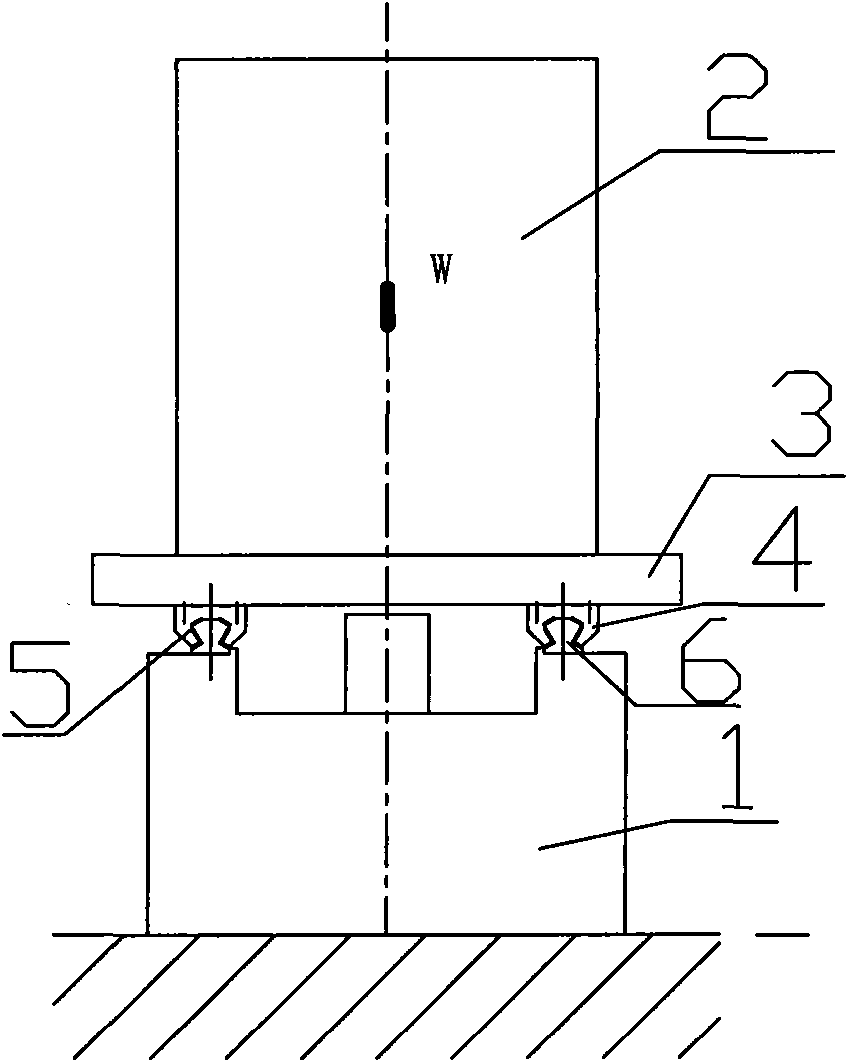

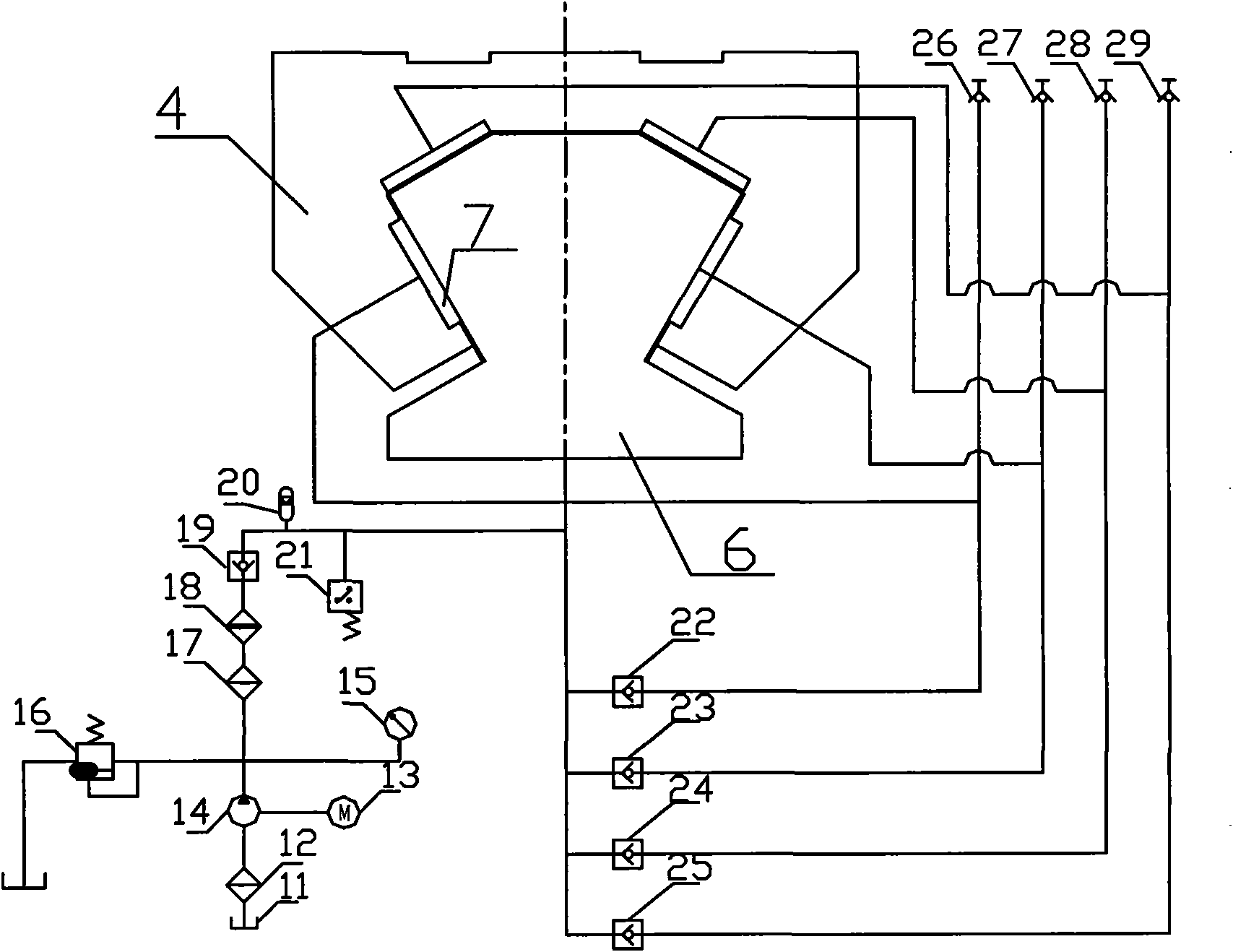

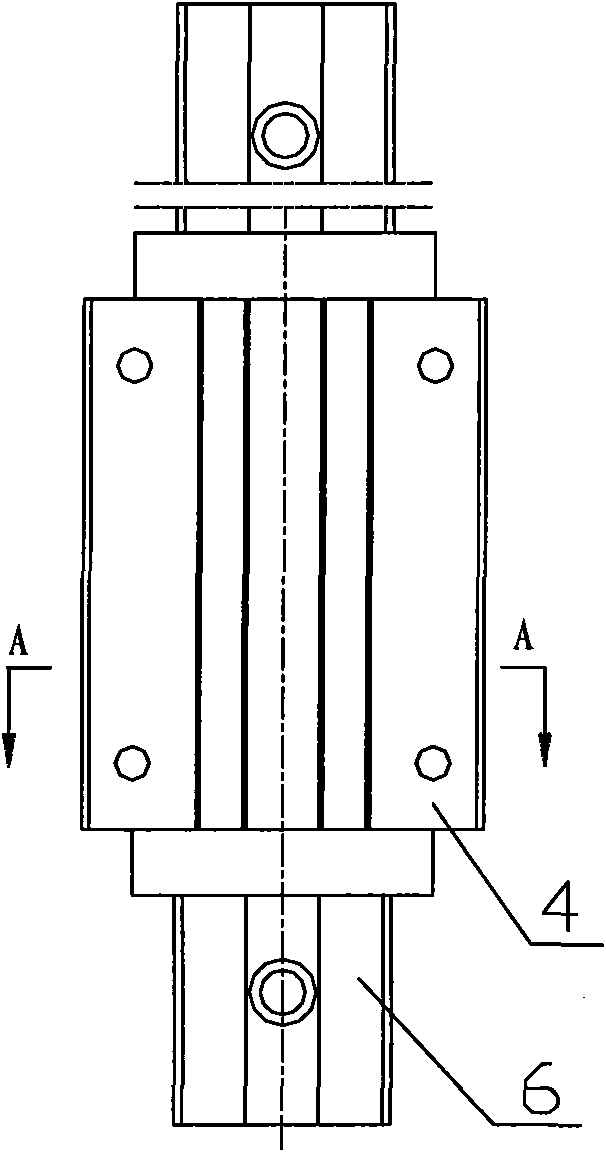

[0029] Such as figure 1 , figure 2 As shown, the precision static pressure linear guide of the present invention includes a bed 1 and a slide seat 3 for placing a workpiece 2. The bottom surface of the slide seat 3 is fixedly provided with a slide block 4, and inside the slide block 4 A groove 5 with an opening downward is formed; and a guide rail 6 that can be embedded in the groove 5 of the slider 4 is fixedly provided on the bed 1 corresponding to the groove 5 of the slider 4 ; The inner peripheral wall of the groove 5 of the slider 4 is provided with a plurality of lubricating grooves 7 that form a lubrication chamber after being combined with the guide rail 6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com