Process for repairing mouth fracture of substation isolating-switch locking pins

A technology of isolating switch and locking pin, applied in switchgear, electrical components and other directions, can solve the problems of increasing the burden of switching operation of substation operators, out-of-tolerance parts, and low economic benefits, achieving low cost, stable arc, The effect of current stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

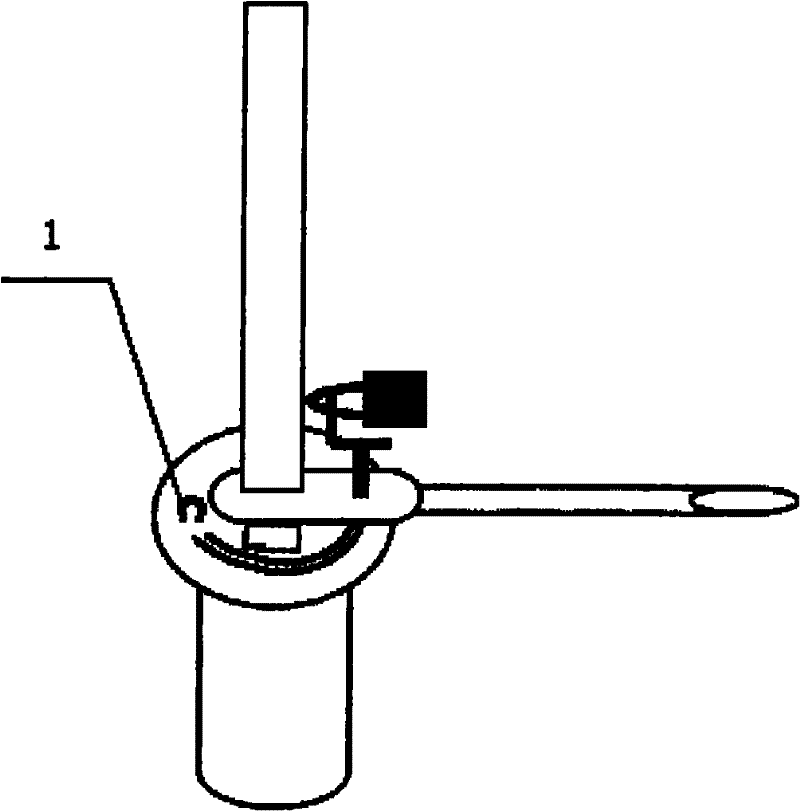

[0020] refer to figure 1 , figure 2 Shown, for the present invention comprises two kinds of molds that use clay brick to make, and a kind of is the cylinder that diameter is 12mm, height 50mm, and a kind of is the sector mold that inner diameter is 28mm, and outer diameter is 68mm. Clay bricks are made of clay (including shale, coal gangue and other powders) as the main raw material, which is processed, shaped, dried and roasted by mud. It can be processed into a variety of styles. According to the compressive strength (N / mm , N / mm2) is divided into 6 strength grades of MU30, MU25, MU20, MU15, MU10, and MU7.5. Clay bricks are made of local materials, cheap, durable, and have the advantages of fire prevention, heat insulation, sound insulation, and moisture absorption.

[0021] Clay brick Al 2 o 3 The content is generally more than 40%, Fe 2 o 3 The content is less than 2.0-2.5%. The clinker in the batching is 65-85%, and the combined clay is 35-15%. The pulverized bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com