Chip with drive integrated circuit and corresponding liquid crystal display

A technology for driving integrated circuits and liquid crystal displays, applied in circuits, electrical solid devices, instruments, etc., can solve the problems of poor display screen, non-conductive, expensive conductive particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

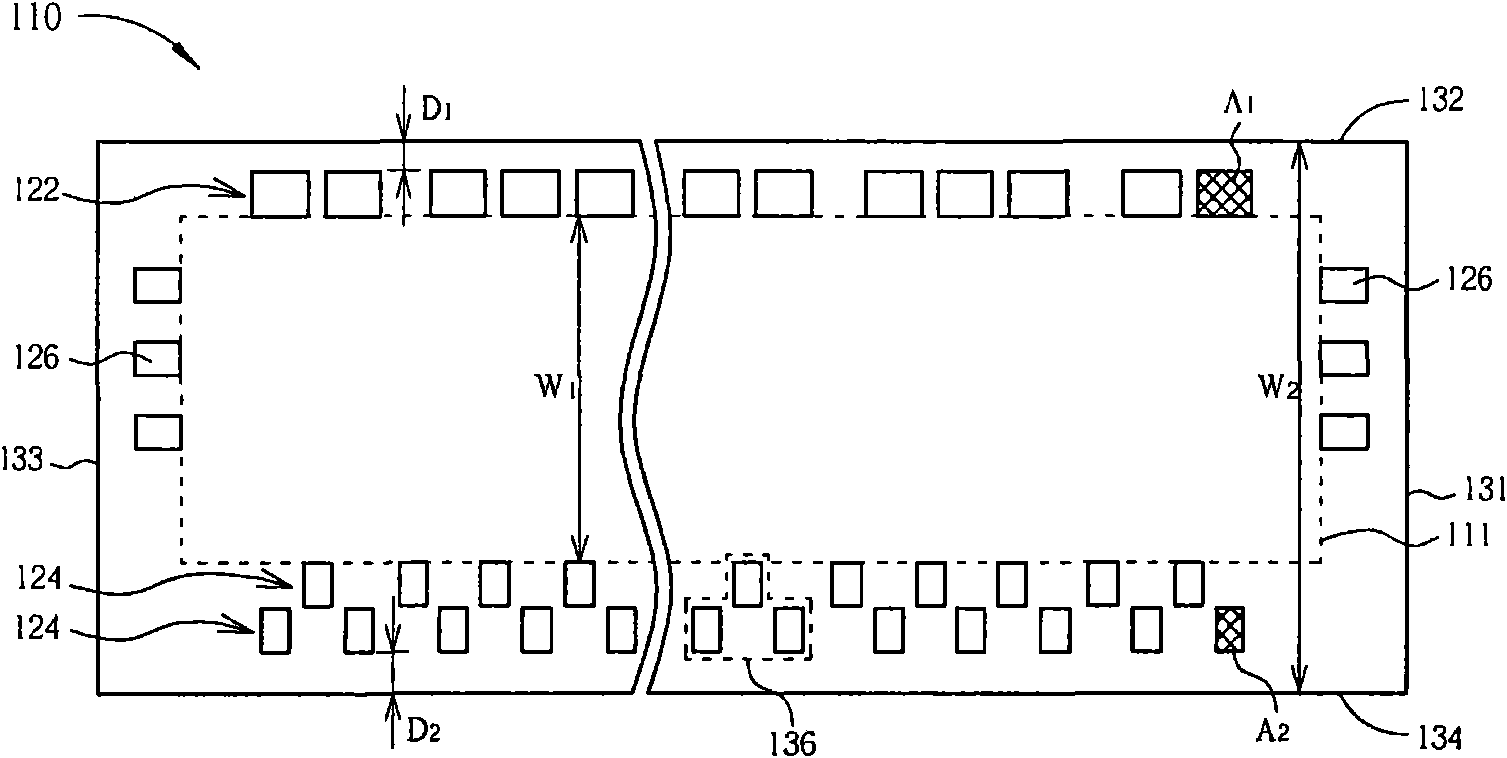

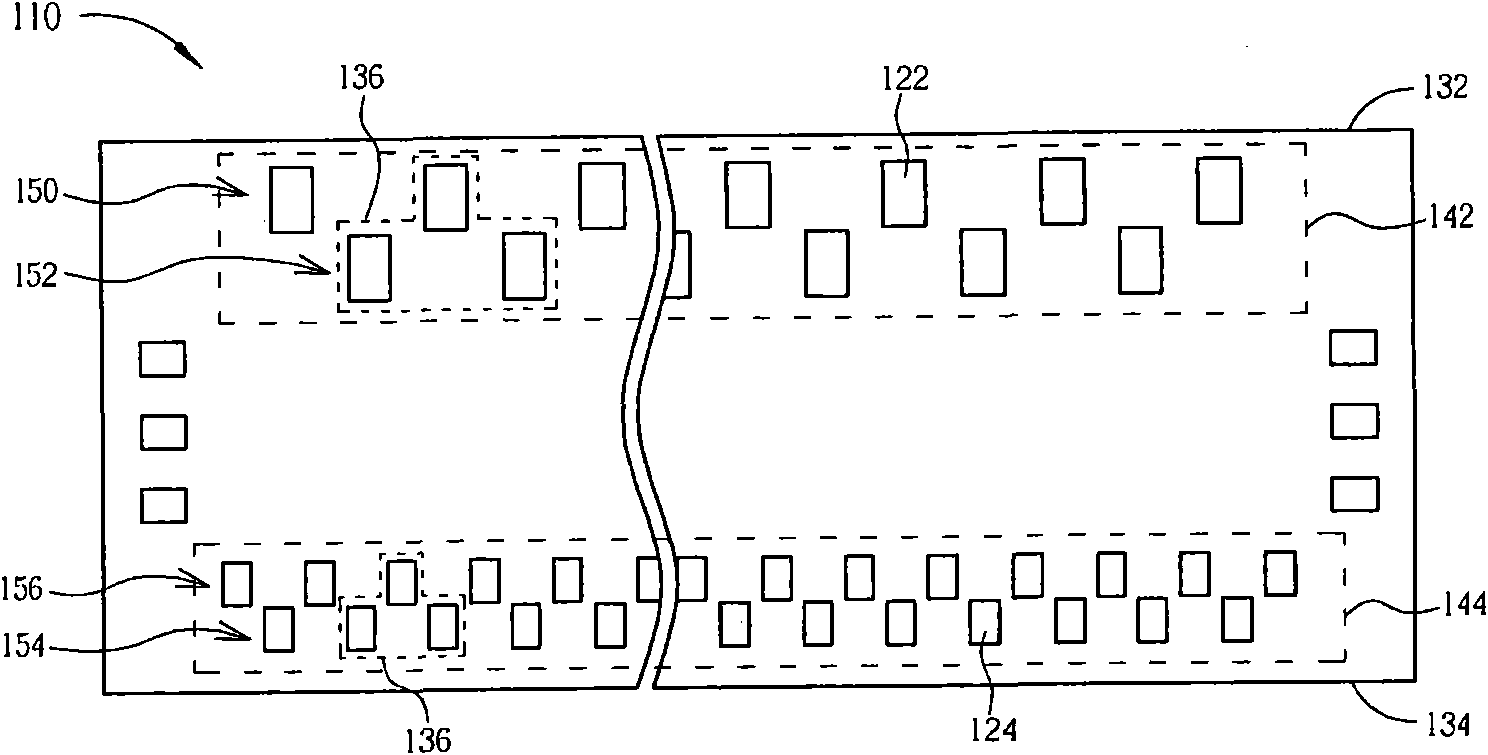

[0010] The present invention provides a display driver chip suitable for COG packaging technology, wherein the area distribution of the bumps on the opposite two edges of the chip is uniform (the total area ratio of the upper edge bumps to the lower edge bumps is about 0.8 to 1.2), so It can improve the problem of poor indentation at the input end and output end. The bump layout of the present invention can be applied to any integrated circuit device, especially a driving chip of a liquid crystal display, such as a source driving chip (source driving chip or source driving IC) listed on the X-axis or a gate driver listed on the Y-axis Chip (gate driving chip or gate driving IC).

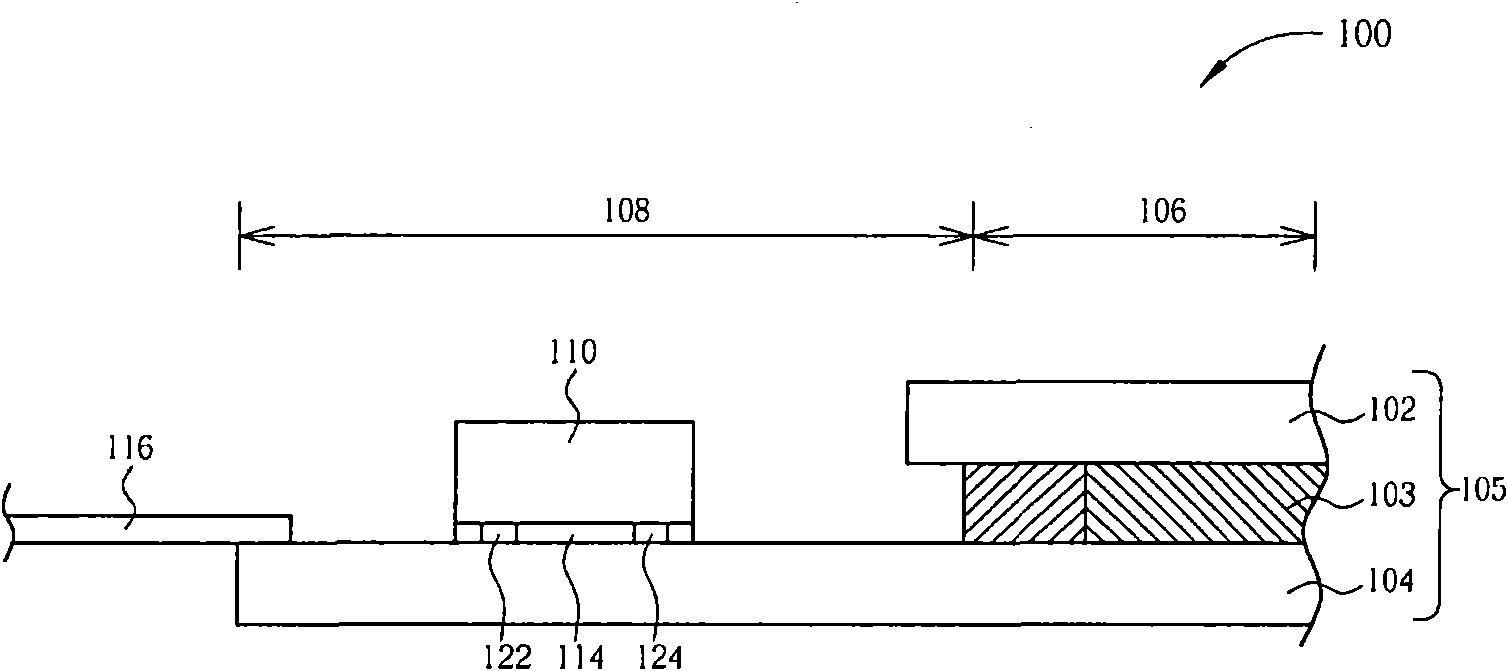

[0011] figure 1 A schematic cross-sectional view of a liquid crystal display 100 showing a first preferred embodiment of the present invention, and figure 2 A schematic structural diagram showing a chip 110 with a driver integrated circuit according to the first preferred embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com