Driver chip and display device

A technology for driving chips and display devices, used in semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve problems such as overvoltage of conductive particles, and achieve the effect of avoiding bad indentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

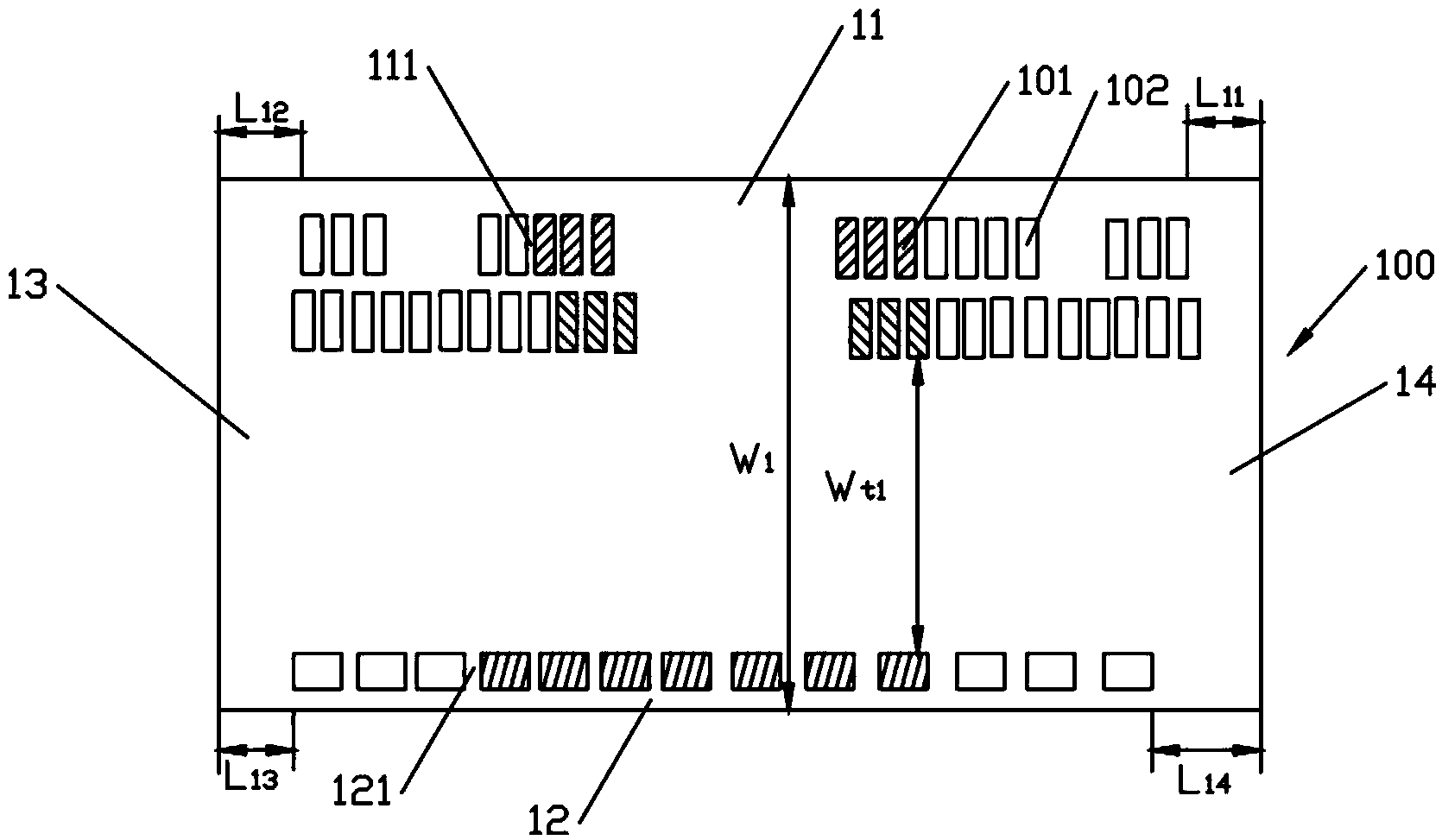

[0031] refer to figure 2 As shown, the driving chip 100 of this embodiment is a source driving chip (source driving chip or source driving IC), and the surface of the driving chip 100 has a first edge 11, a second edge 12, and a third edge 13 opposite to each other. and the fourth edge 14 , the third edge 13 and the fourth edge 14 intersect with the first edge 11 and the second edge 12 . Preferably, the first edge 11 and the second edge 12 are parallel to each other, the third edge 13 and the fourth edge 14 are parallel to each other, and the driving chip 100 has a rectangular structure. The driving chip 100 includes: a plurality of connecting bumps 101 and a plurality of supporting bumps 102 . A plurality of connecting bumps 101 and supporting bumps 102 are arranged along the first edge 11 of the driver chip 100 to form at least one first bump row 111, the first bump row 111 in this embodiment is two rows, each row There is at least one supporting bump 102 at both ends of ...

Embodiment 2

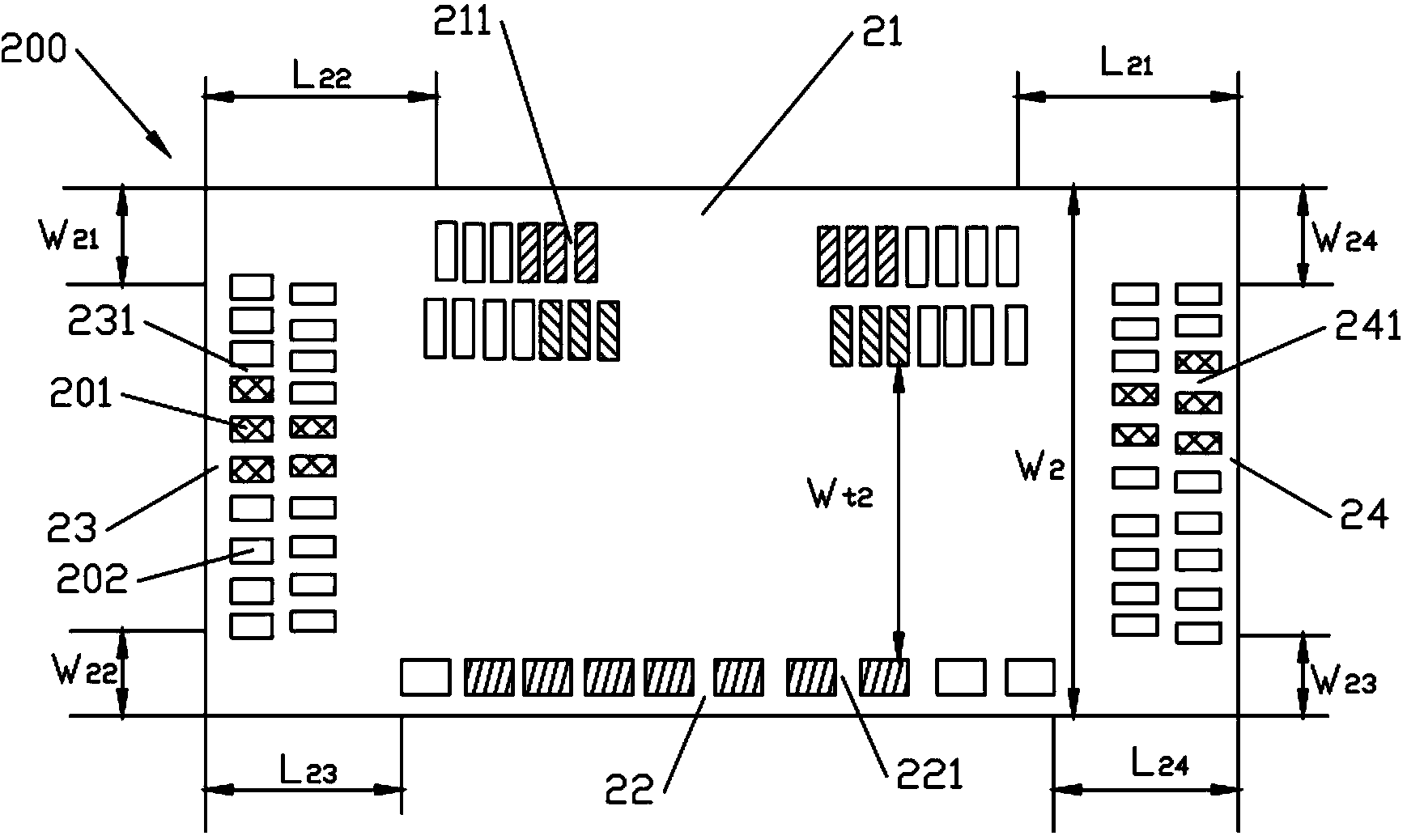

[0034] refer to image 3As shown, the driving chip 200 of this embodiment is a gate driving chip (gate driving chip or gate driving IC), and the driving chip 200 has a rectangular structure. The surface of the driver chip 200 has a first edge 21 , a second edge 22 , a third edge 23 , and a fourth edge 24 opposite to each other; the third edge 23 and the fourth edge 24 intersect with the first edge 21 and the second edge 22 . Preferably, the first edge 21 and the second edge 22 are parallel to each other, the third edge 23 and the fourth edge 24 are parallel to each other, and the driving chip 200 has a rectangular structure. The driving chip 200 includes: a plurality of connecting bumps 201 and a plurality of supporting bumps 202 . A plurality of connecting bumps 201 and supporting bumps 202 are arranged along the first edge 21 of the driver chip 200 to form at least one first bump row 211, the first bump row 211 in this embodiment is two rows, each row There is at least one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com