Method of producing polyester amide hot melt adhesive

A technology of polyester amide and its manufacturing method, which is applied in the direction of adhesives, etc., can solve the problems of uncontrollable relative content and sequence distribution of ester bond and amide bond, uncertain melting range and proportion of polyester glue and polyamide glue, etc., to achieve Plump appearance quality, not easy to store, excellent dry cleaning resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

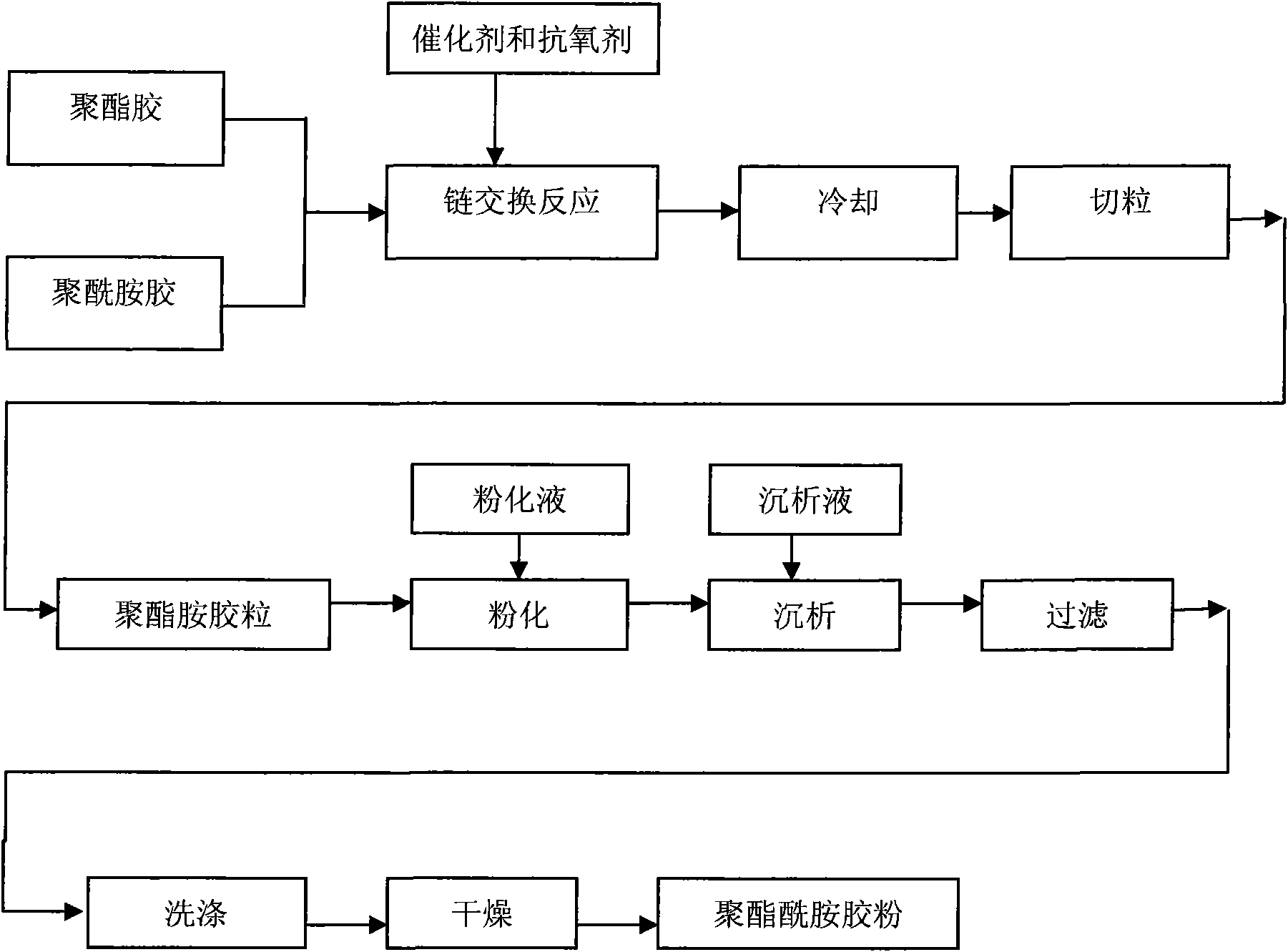

[0015] refer to figure 1 An embodiment of the method for producing polyester amide hot-melt adhesive of the present invention, the polyester adhesive with a melting range of 130-140°C and the polyamide adhesive with a melting range of 140-150°C are added to the reactor at a weight ratio of 1:1. Then add polyester glue and polyamide glue total weight 0.1% acetate catalyst and 0.01% phosphite antioxidant. Under the protection of nitrogen, slowly heat until the colloidal particles melt, start stirring, raise the temperature to 240-250°C and maintain for 3-4 hours to carry out chain exchange reaction. Then slowly depressurize until the melt viscosity reaches 77.3Pa·s, remove the low molecular matter in the reaction system, and when the melt viscosity reaches the requirement, fill nitrogen to normal pressure and then change to 1.08 atmospheric pressure, and press the melt material in a strip shape Put it into a water tank, cool, and cut into pellets to obtain colloidal pellets.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com