Method for producing through-hole structure in PDMS micro-fluidic chip

A technology of microfluidic chip and manufacturing method, which is applied in the field of lab-on-a-chip, can solve problems affecting the application of microfluidic chip, damage the structure of microfluidic chip, and irregular shape of through holes, etc., and achieve batch processing and production, Improve the production density and ensure the effect of regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

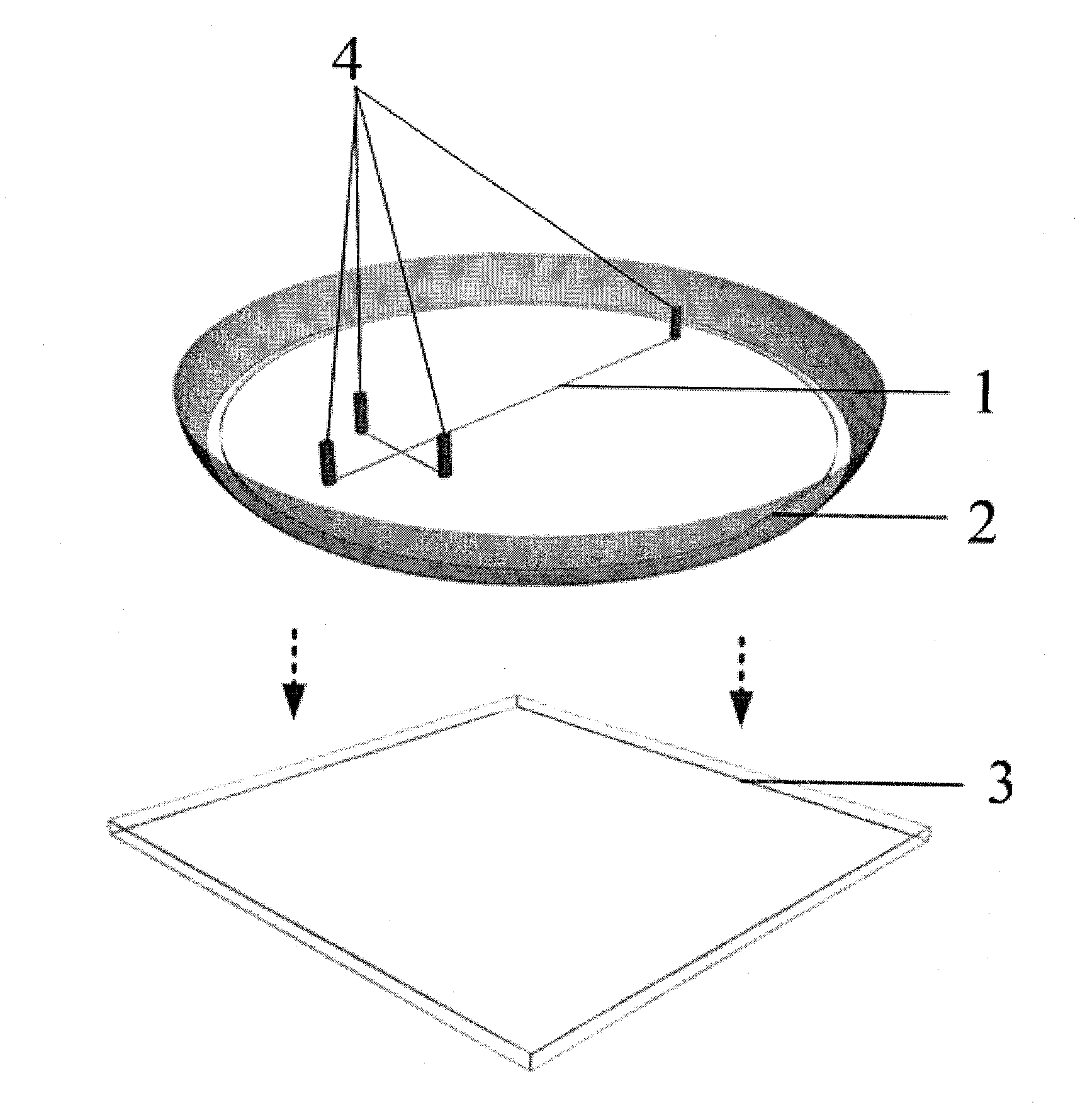

[0022] Example 1. Fabrication of through-hole structures used as sample inlet and sample outlet on the PDMS microfluidic chip

[0023] 1.1 Magnetic microcolumn immobilization

[0024] The present invention can be used to make the through-hole structure of sample inlet and sample outlet on PDMS microfluidic chip, as figure 1 As shown, first, a microfluidic chip mold 1 is made by photolithography, and the chip mold 1 is placed in a container 2 kneaded by aluminum foil; then, a stainless steel plate 3 is placed at the bottom of the container corresponding to the chip mold, and placed on the chip Place the micro-magnetic column 4 above the mold corresponding to the position where the through-hole structure is to be made, and fix it with magnetic force; after fixing the micro-magnetic column, pour PDMS mixed with PDMS prepolymer and curing agent (mass ratio 10:1) in the container The prepolymer is placed on a hot plate at 80°C to cure for 1 hour; after the PDMS is cured, the stain...

Embodiment 2

[0029] Example 2. Fabrication of a high-density through-hole structure on a PDMS microfluidic chip

[0030] If multiple through-hole structures are to be made on the PDMS microfluidic chip, and the distance between the through-holes is small, the mutual magnetic force between adjacent magnetic columns will cause the position of the magnetic columns to shift, affecting the positioning and fixing of the micro-columns. ; In order to avoid the impact of the mutual magnetic force between adjacent magnetic columns on the positioning and fixing of the micro-columns when making a higher-density through-hole structure on the PDMS microfluidic chip, the following methods can be used to fix the micro-columns (such as Figure 4Shown): first cast a plate 8 based on PDMS material, and make a group of small holes on this plate with a puncher, the center position of the small hole basically corresponds to the center of the through hole to be made on the mold, and the diameter of the small hole...

Embodiment 3

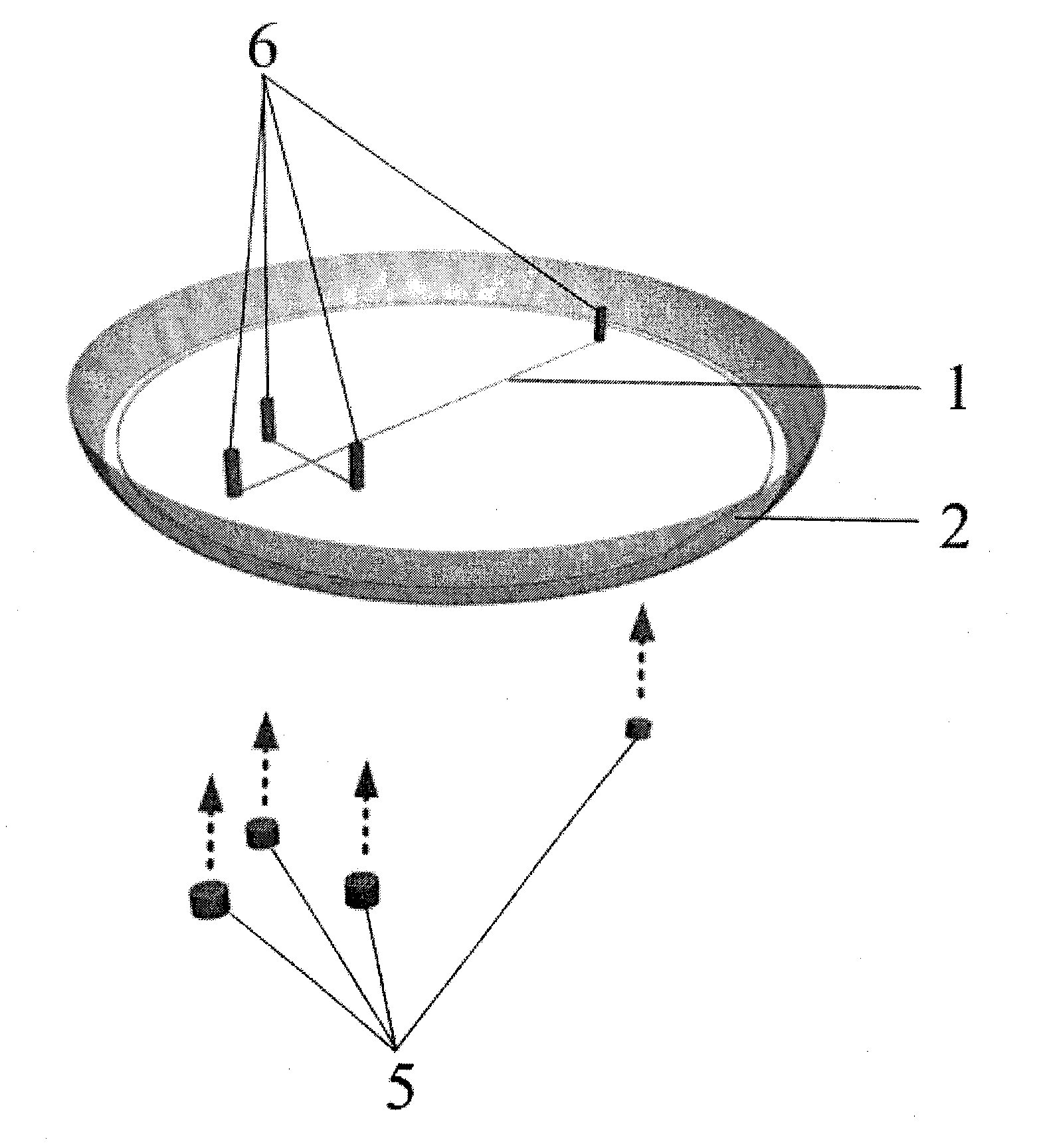

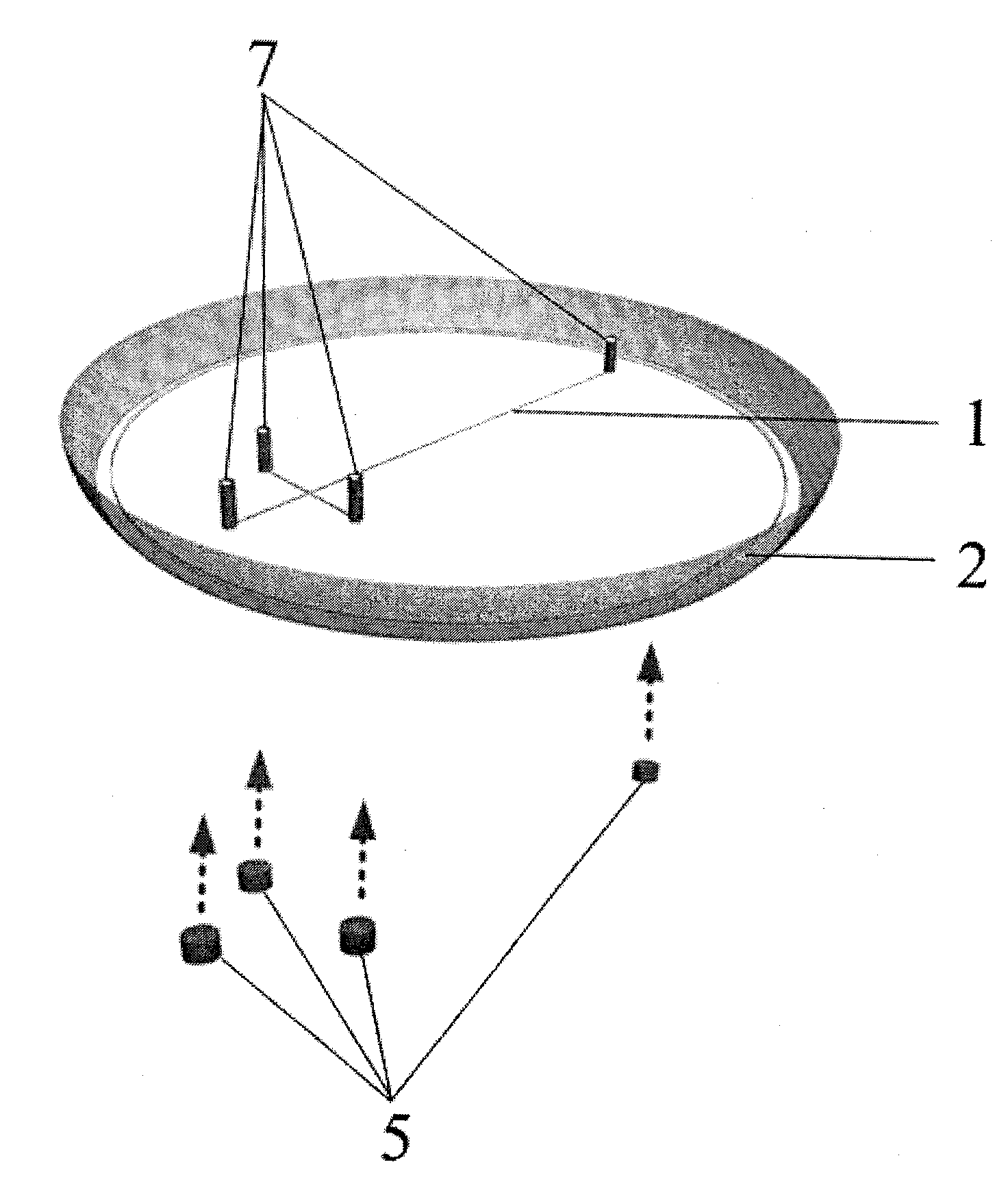

[0031] Example 3. Fabrication of a through-hole structure connecting different micropipe layers on a PDMS microfluidic chip

[0032] The present invention is also used to make through-hole structures connected to different micropipe layers on the PDMS microfluidic chip, such as Figure 5 and Image 6 As shown, at first the bottom micropipeline layer mold and the upper micropipeline layer mold containing the micro-through-hole structure are made respectively. Under the aluminum foil paper container 2 equipped with the chip mold 1, the fixing of the stainless steel micro-column at the position of the through hole is realized. The difference from Example 2 is that the bottom chip mold 1 is fixed with a group of magnetic force for making the chip opening structure. In addition to the stainless steel microcolumns 6, a group of stainless steel microcolumns 9 with a smaller diameter for making connection through-hole structures are also fixed. After fixing the microcolumns, pour th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com