Method for preparing anode material of metal oxide nano-sheet lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, nickel oxide/nickel hydroxide, circuits, etc., can solve the problems of high equipment requirements and low output, and achieve simple preparation process, low difficulty, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Firstly, cobalt acetate and lithium acetate were formulated into solutions according to the stoichiometric ratio of 1:1.05, then lithium acetate and oxalic acid were added dropwise to the cobalt acetate solution at the same time, and acetic acid was added to make the acetic acid excessive, and the pH was adjusted to 3.5; the temperature was raised to 80 ℃ and stirring, the stirring speed is 500rpm, so that the solution phase forms a rheological phase, continue stirring for 24h, and then let the solution dry up. The precursor powder is pre-calcined in a high-temperature resistance furnace at a temperature of 400°C for a calcination time of 5 hours; the product is taken out for grinding and then sintered at a high temperature at a sintering temperature of 800°C for a calcination time of 8 hours to finally obtain a layered lithium cobalt oxygen nanometer piece.

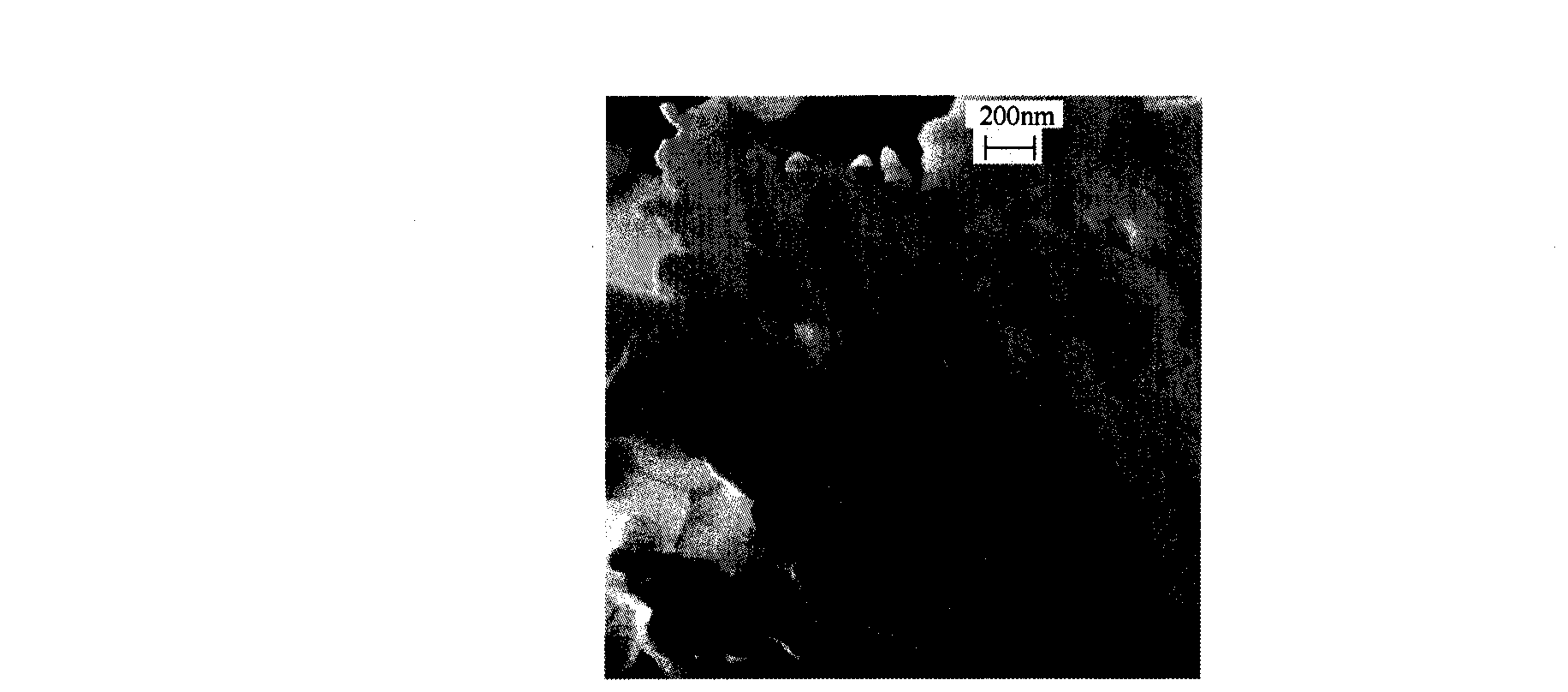

[0027] The scanning electron microscope image of layered lithium cobalt oxide nanosheets is shown in figure 1 ...

Embodiment 2

[0030] Firstly, manganese acetate, nickel acetate and lithium acetate were formulated into solutions according to 0.58:0.25:1.29, and the nickel acetate and manganese acetate solutions were mixed thoroughly, then lithium acetate and oxalic acid were added dropwise to the mixed solution at the same time, and acetic acid was added to make the acetic acid Excessive, adjust the pH to 4; raise the temperature to 80°C and stir the solution phase until the rheological phase is formed, continue stirring for 48h, and then let the solution dry up. The precursor powder was pre-calcined in a high-temperature resistance furnace at a temperature of 400°C for 5 hours; the product was taken out for grinding and then sintered at a high temperature at a temperature of 900°C for 12 hours to obtain Li(Li 0.17 Ni 0.25 mn 0.58 )O 2 Layered LiNiMnO nanosheets.

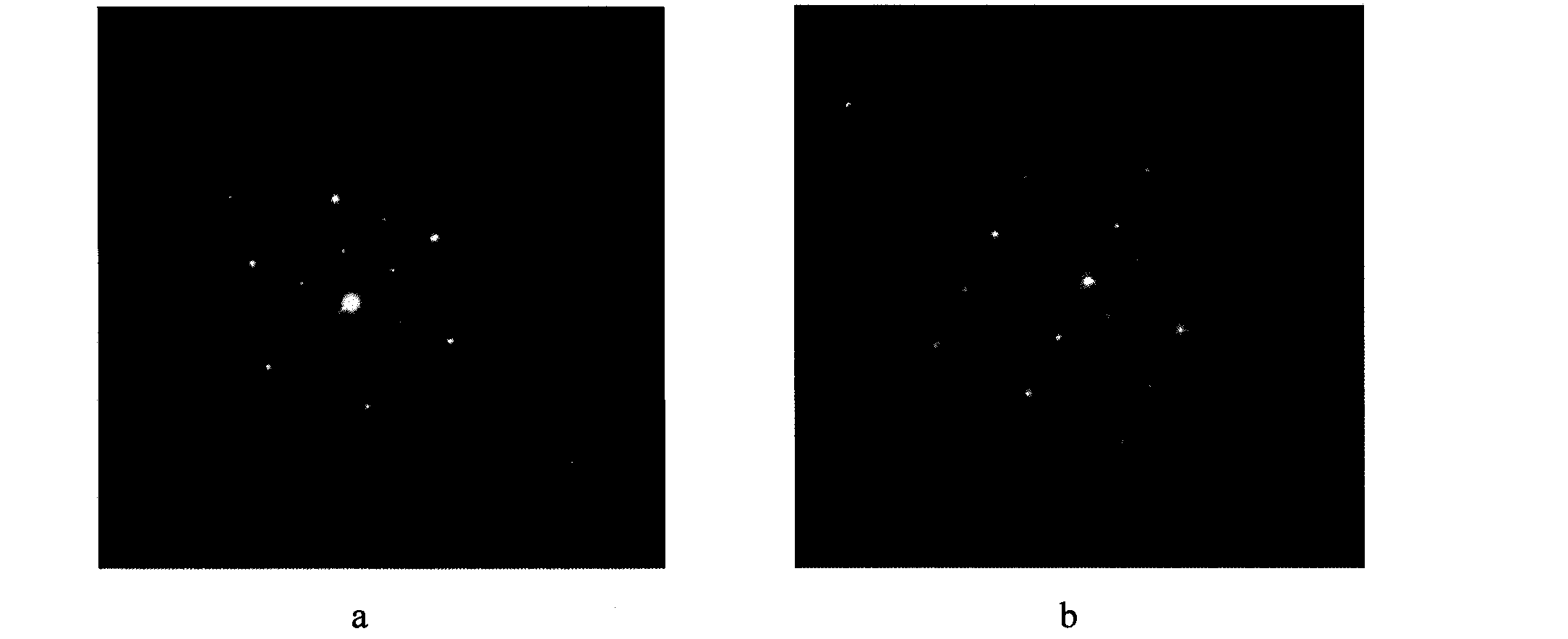

[0031] The selected area electron diffraction pattern of layered lithium nickel manganese oxide nanosheets is shown in image 3 . ima...

Embodiment 3

[0036] Firstly, manganese acetate, nickel acetate, cobalt acetate and lithium acetate were formulated into solutions at 0.5:0.17:0.17:1.29, and the nickel acetate, cobalt acetate and manganese acetate solutions were mixed thoroughly, then lithium acetate and oxalic acid were added dropwise to the mixed solution at the same time and add acetic acid to make excess acetic acid, adjust the pH to 4; raise the temperature to 80°C and stir the solution phase until the rheological phase is formed, continue stirring for 72h, and then let the solution dry up. The precursor powder was pre-calcined in a high-temperature resistance furnace at a temperature of 400°C for 5 hours; the product was taken out for grinding and then sintered at a high temperature at a temperature of 900°C for 12 hours to obtain Li(Li 0.17 Ni 0.17 co 0.17 mn 0.5 )O 2 Layered lithium nickel cobalt manganese oxide nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com