Method for coating phosphor powder layer on LED chip and manufacture of LED device

A technology for LED chips and LED devices, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult to control consistency, high cost, and poor consistency of the amount of phosphor powder in LED chips. The effect of short curing time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

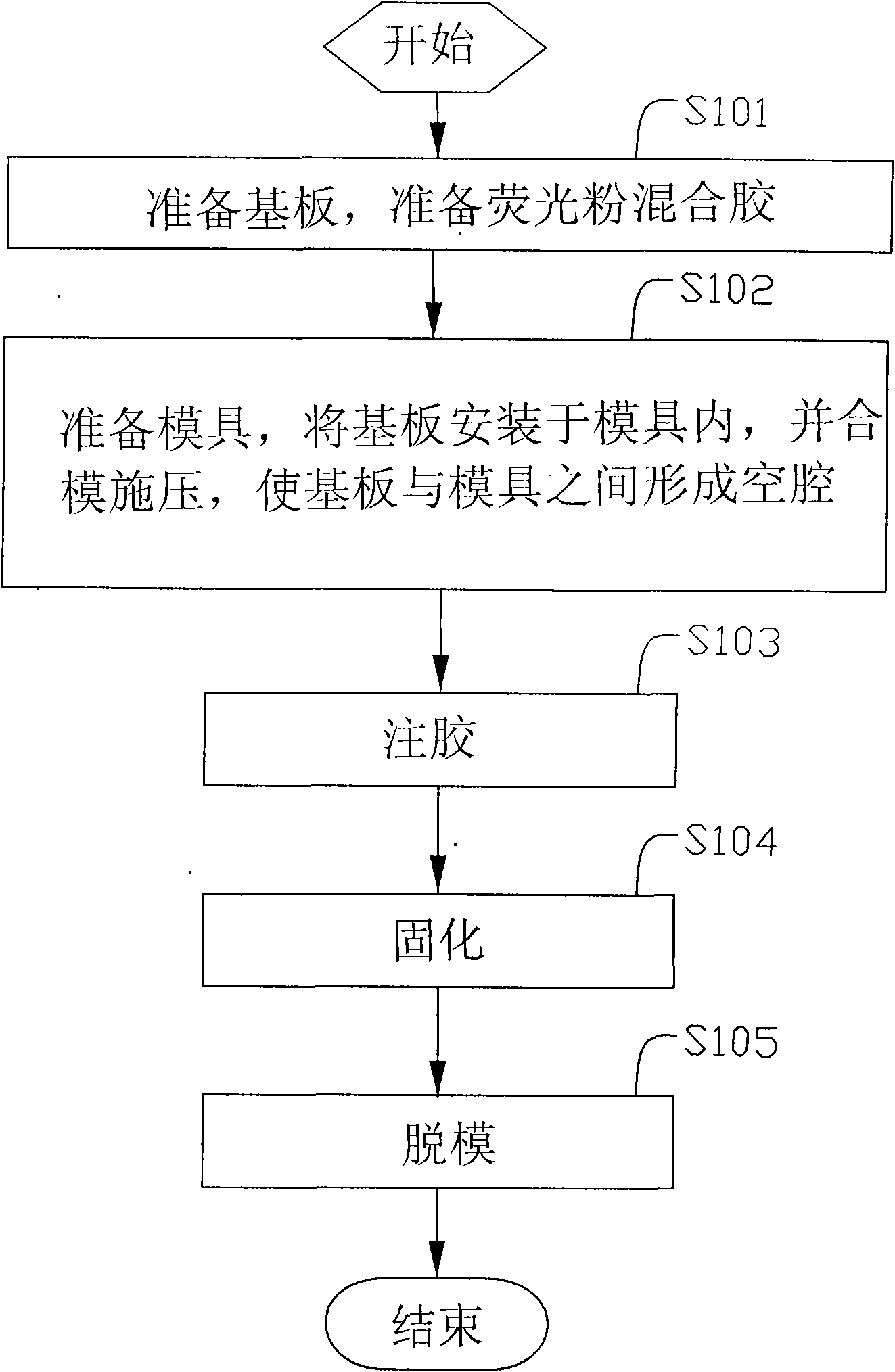

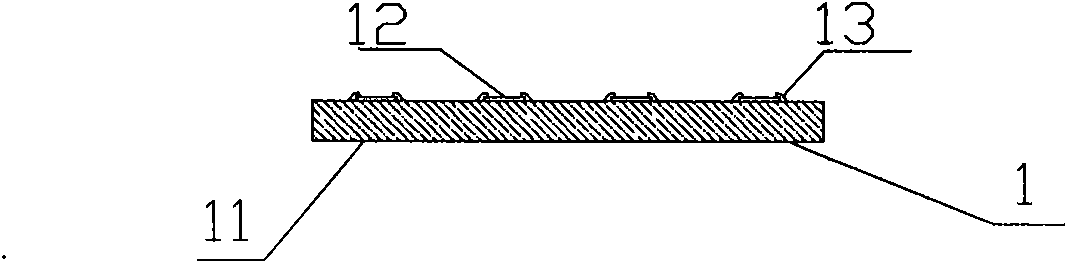

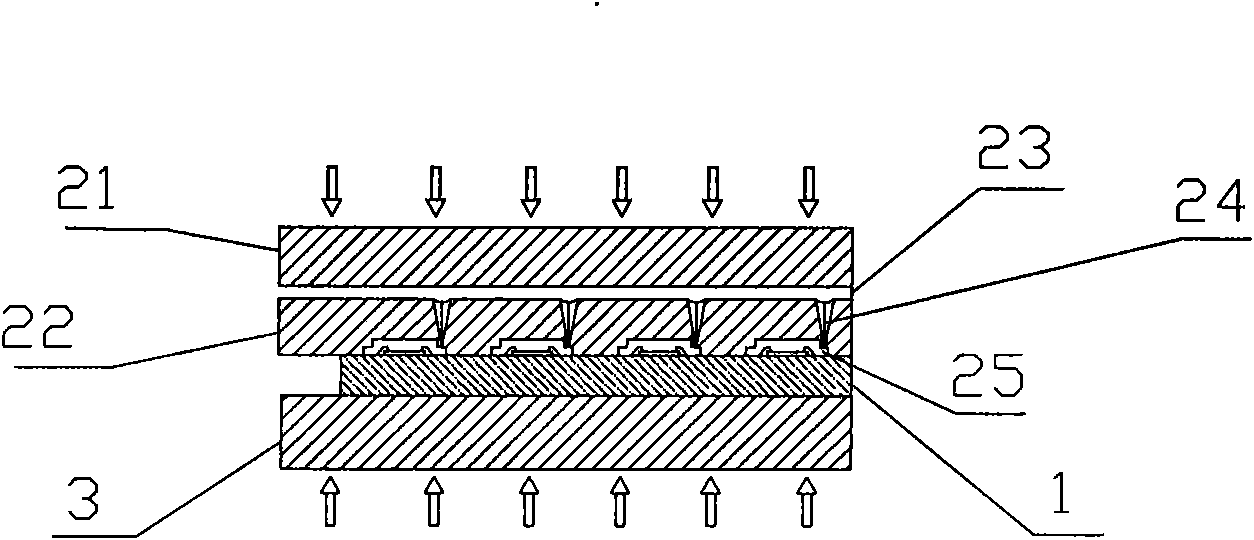

[0024] figure 1 Shown is a flowchart of a method for coating a phosphor layer on an LED chip in an embodiment of the present invention. see also Figure 2A ~ Figure 2D , utilize a mold to implement for the present invention figure 1 schematic diagram. In step S101 , the substrate 1 is prepared, and the phosphor powder mixture 4 is prepared, wherein the substrate 1 is mounted with LED chips 12 . In this embodiment, preparing the substrate 1 includes: dispensing glue, that is, dispensing an adhesive (not shown in the figure) on the substrate 1; bonding the LED chip 12 on the adhesive; connecting the leads 13, namely Connect the electrodes (not shown in the figure) on the LED chip 12 and the conductive layer (not shown in the figure) on the substrate to form a loop to obtain the following Figure 2A A substrate 1 on which LED chips 12 are mounted is shown. In this embodiment, the number of LED chips can be one, or two or more.

[0025] The preparation of the phosphor powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com