High-performance anti-hydrolysis and high-density resin material for coining polyurethane leather and preparing method thereof

A technology of polyurethane resin and polyurethane leather is applied in the field of high-performance hydrolysis-resistant high-density embossed polyurethane leather resin material and its preparation field, which can solve the problems of poor embossing effect of hydrolysis-resistant high-stripping resin, and improve the embossing effect. The effect of improving the embossing performance, broadening the application field and improving the embossing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

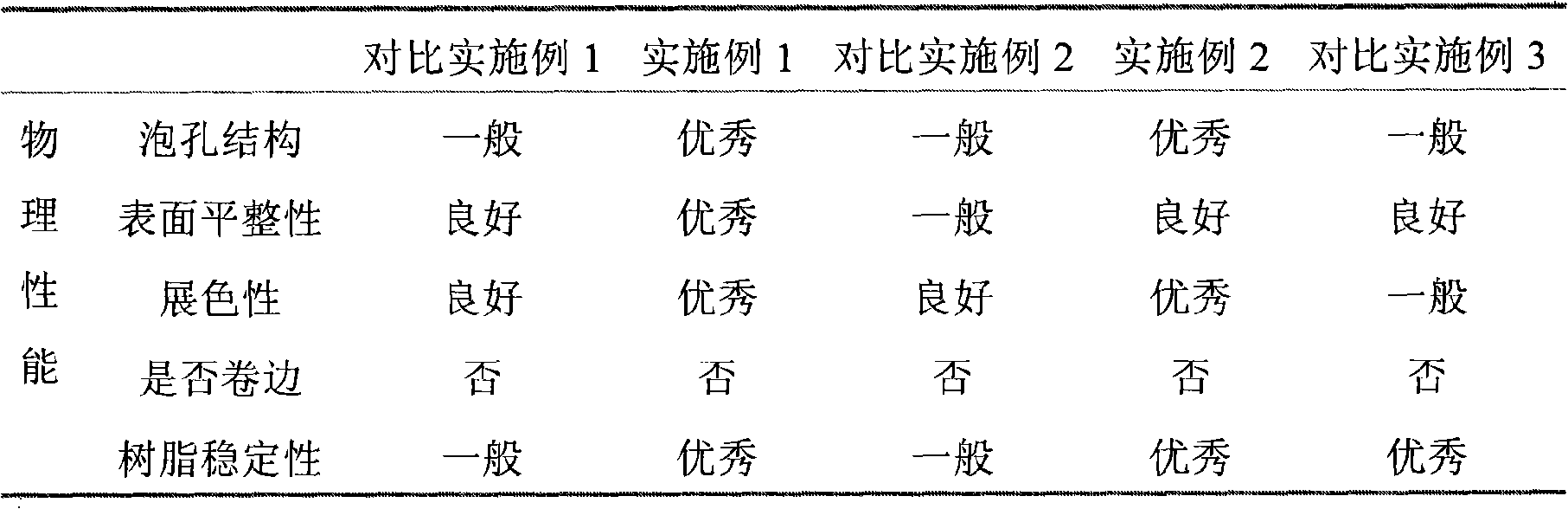

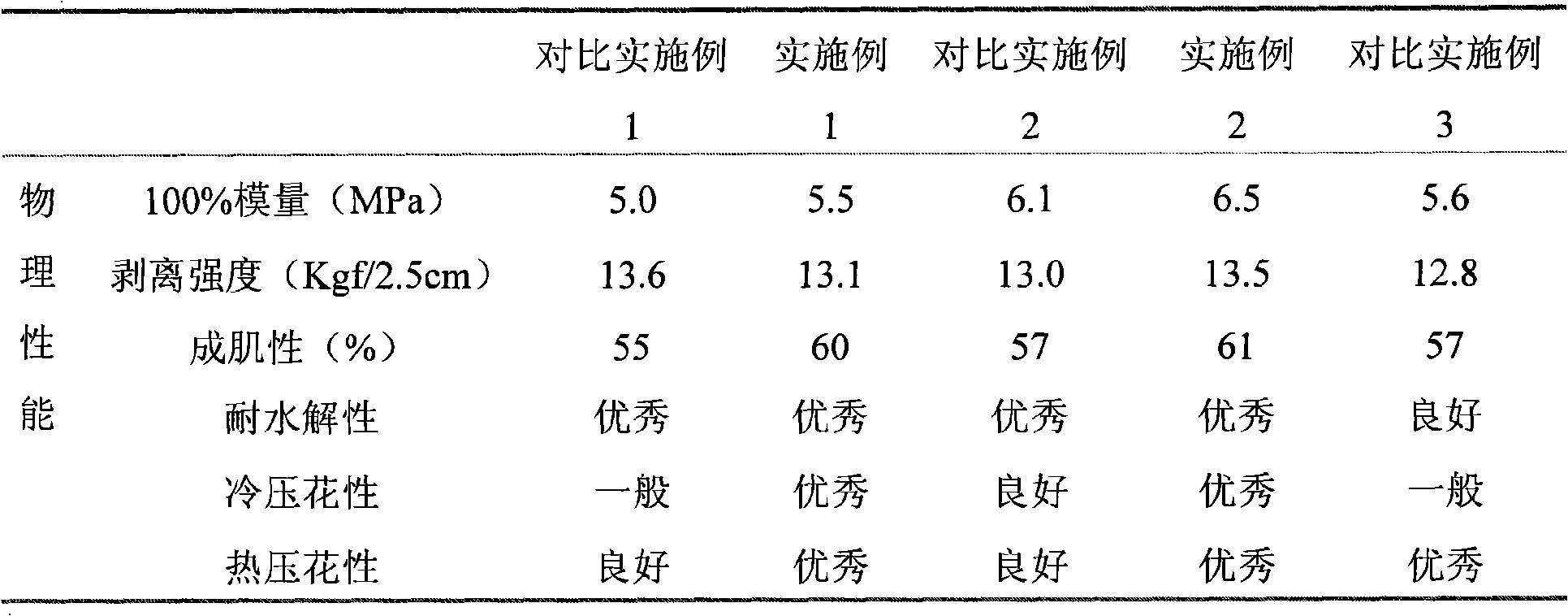

Examples

Embodiment 1

[0015] Component A: Mix 20 kg of polyadipate polyol I and polyadipate polyol II (weight-average molecular weight 2000, functionality 2) with 25 kg of DMF and add to the reaction kettle, then add two 2.5 kg of phenylmethane diisocyanate (MDI); react at a temperature of 60-80°C, and add 50 kg of DMF and 10 kg of polyether polyol I (weight-average molecular weight of 2000, functional degree is 2) and 5 kilograms of polyadipate polyol III (weight-average molecular weight is 2000, functional degree is 2); Add 2 kilograms of diphenylmethane diisocyanate (MDI) after mixing evenly, at a temperature of 60 After fully reacting at ~80°C, add 30kg of DMF, 4.5kg of ethylene glycol, and 3.0kg of 1,4-butanediol; after stirring evenly, add 14kg of MDI and react at a temperature of 60-80°C. When the viscosity increases to Add 23kg of DMF at 200Pa·s / 65°C; finally add 0.5kg of dehydrating agent, stir thoroughly, mix evenly, discharge, seal and store for later use.

[0016] Component B: A total ...

Embodiment 2

[0019] Component A: Mix 20 kg of polyadipate polyol I and polyadipate polyol II (weight-average molecular weight 2000, functionality 2) with 25 kg of DMF and add to the reaction kettle, then add two 2.0 kg of phenylmethane diisocyanate (MDI), 0.4 kg of toluene diisocyanate (TDI); react at a temperature of 60-80°C, add 50 kg of DMF, 10 kg of poly Ether polyol I (the weight-average molecular weight is 2000, and the functionality is 2) and 10 kilograms of polyadipate polyol III (the weight-average molecular weight is 4000, and the functionality is 2); add diphenylmethane diisocyanate ( MDI) 2 kg, add 35 kg of DMF, 5.5 kg of ethylene glycol, and 2.0 kg of 1,4-butanediol after fully reacting at a temperature of 60-80°C; add 14.5 kg of MDI after stirring evenly, React at 80°C, add 25kg of DMF when the viscosity increases to 200Pa·s / 65°C; finally add 0.5kg of dehydrating agent, stir well, mix evenly, discharge, seal and store for later use.

[0020] Component B: a total of 15 kg of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com