Method for manufacturing chromium-zirconium-copper tubes for electrode material

A technology of electrode material and manufacturing method, which is applied in the field of stretching of metal pipes, can solve the problems of large central hole position deviation of copper pipes, poor aperture accuracy and finish, waste of manpower and material resources, etc., and achieves reduced electricity costs and high aperture accuracy , the effect of staff reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Finished product specifications: chrome-zirconium copper tube with an outer diameter of φ6.0mm and an inner diameter of φ1.2±0.05mm

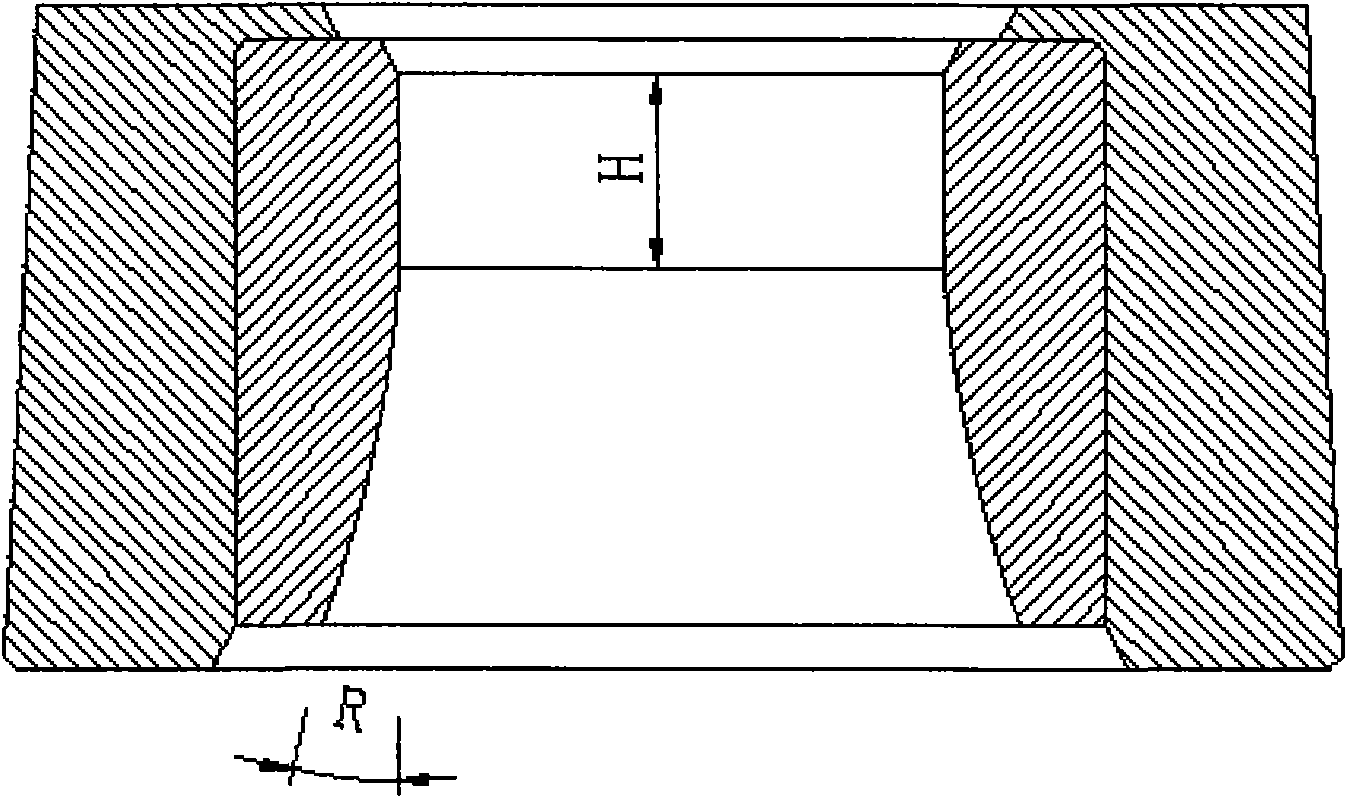

[0019] The hard chromium-zirconium copper tube blank with an outer diameter of φ38mm and a wall thickness of 6.3mm is subjected to the first lining drawing, and then 4 times of empty drawing to an outer diameter of φ18.85mm and an inner diameter of φ10.0mm; and then the second The secondary lining is drawn to an outer diameter of φ18.1mm and an inner diameter of φ7.75mm; the copper tube after the second lining is vacuum annealed and softened at 410-430°C, kept for 2 hours, cooled for 12 hours, and then carried out 4 times Empty drawing to an outer diameter of φ11mm and an inner diameter of φ2.65mm, and the copper pipe after 4 air-drawings is then subjected to a third liner drawing to an outer diameter of φ10.50mm and an inner diameter of φ2.50mm; finally select as shown in the attached drawing The sizing length H is 0.5 ~ 0.9mm, and the c...

Embodiment 2

[0021] Finished product specifications: chrome-zirconium copper tube with an outer diameter of φ10.0mm and an inner diameter of φ1.8±0.05mm

[0022] The hard chrome-zirconium copper tube billet with an outer diameter of φ40mm and a wall thickness of 10mm is subjected to the first lining drawing correction, and then 4 times of empty drawing to an outer diameter of φ26.0mm and an inner diameter of φ11.5mm; and then the second The secondary lining is drawn to an outer diameter of φ25mm and an inner diameter of φ10.1mm; the copper tube after the second lining is vacuum annealed and softened at 530-570°C, kept warm for 2 hours, and cooled for 15 hours; and then carried out 3 times of empty drawing When the outer diameter is φ15mm and the inner diameter is φ3.85mm, the copper pipe after 3 times of empty drawing is subjected to the third lining drawing to the outer diameter of φ14.5mm and the inner diameter is φ3.7mm; finally, the sizing is selected as shown in the attached drawing T...

Embodiment 3

[0024] Finished product specifications: chrome-zirconium copper tube with an elliptical shape, the outer diameter is 7.92*7.62mm, and the inner diameter is φ1.2±0.05mm

[0025] The hard chromium-zirconium copper tube blank with an outer diameter of φ38mm and a wall thickness of 8mm is subjected to the first lining drawing, and then 5 times of empty drawing to an outer diameter of φ21.0mm and an inner diameter of φ9.5mm; and then the second time The lining is drawn to an outer diameter of φ20mm and an inner diameter of φ8.45mm; the copper tube after the second lining is annealed and softened at 460-480°C in vacuum, kept for 2 hours, and cooled for 13 hours; The diameter is φ13mm, the inner diameter is φ3.05mm, and the copper pipe after three empty drawing is subjected to the third lining drawing to the outer diameter of φ12.3mm, and the inner diameter is φ2.8mm; finally, the sizing length H shown in the attached drawing is selected. 0.6 ~ 1.3mm, the cavity angle R is 14 ~ 20° f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com