Electric connector terminal

An electrical connector and terminal technology, applied in the field of electrical connector terminals, can solve the problems of non-conformity with electronic products, short electrical conduction path, large space, etc., and achieve the effect of shortening the electrical conduction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

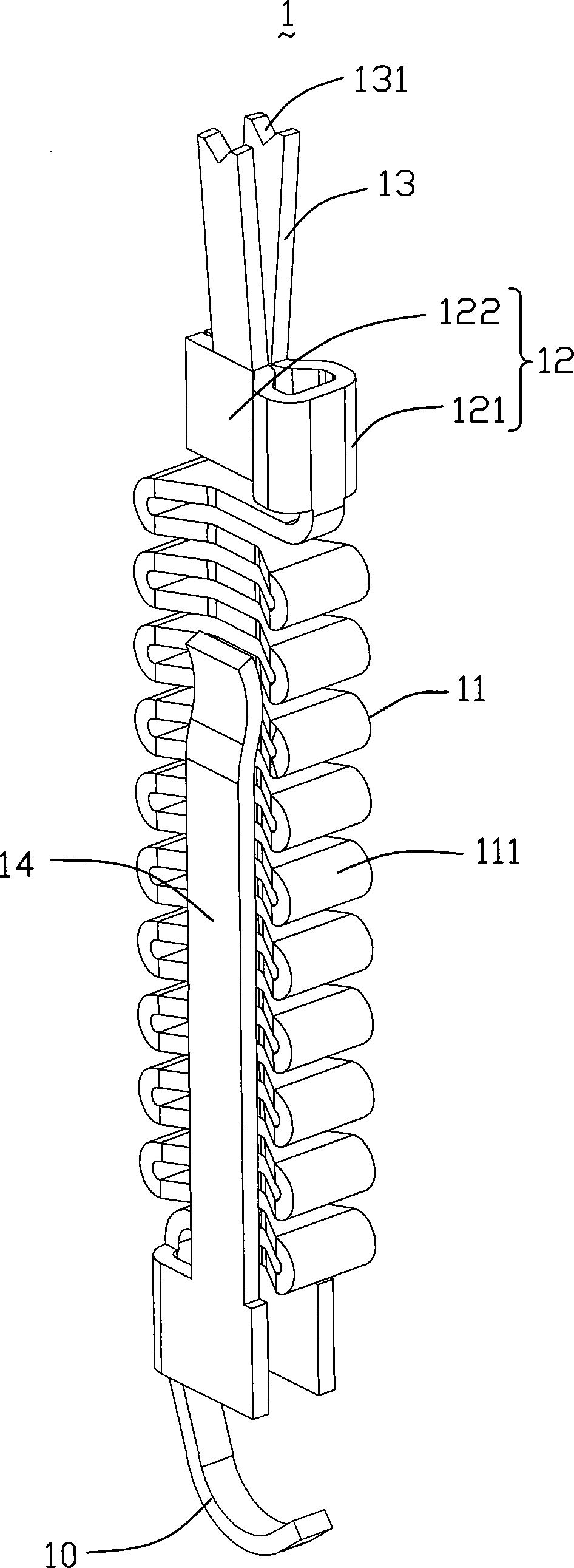

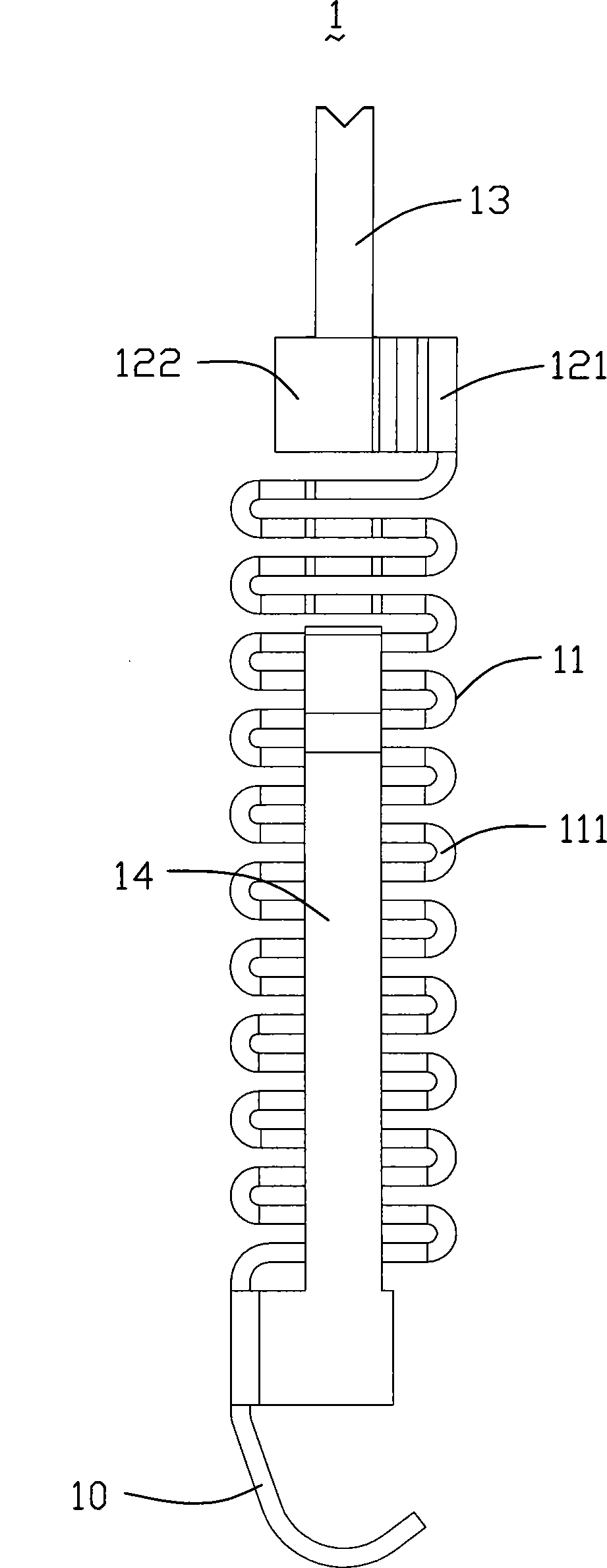

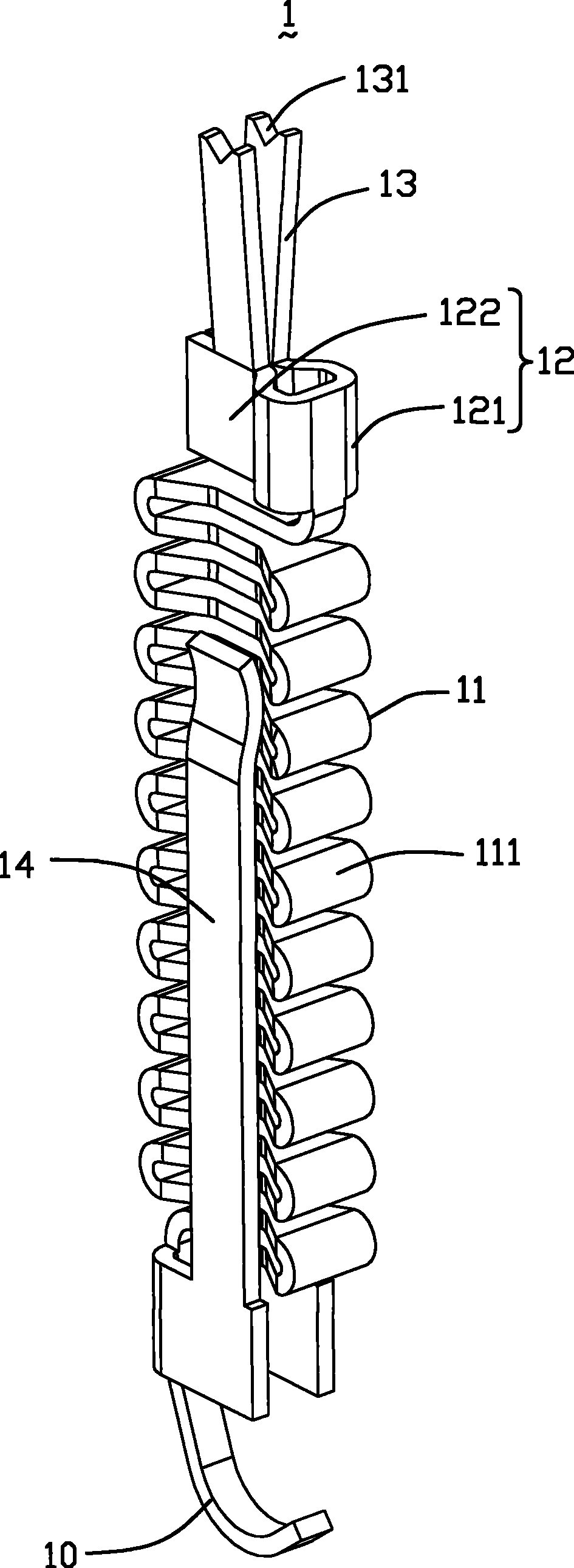

[0011] Below, will combine figure 1 and figure 2 The specific implementation manner of the electrical connector terminal 1 of the present invention is introduced. The electrical connector terminal 1 of the present invention includes a hook-shaped first contact portion 10, an elastic arm 11 extending vertically upward from one end of the first contact portion 10 in the same plane through several times of bending, and continuing upward from one end of the elastic arm 11. An extended support arm 12 and a pair of second contact portions 13 connected to the support arm 12 . The elastic arm 11 is bent each time to form a folding unit 111 , and each folding unit 111 has a shape with thick sides and a thin middle. The support arm 12 includes an arc-shaped support arm 121 connected to the elastic arm 11 and a flat plate-shaped support arm 122 parallel to the free end of the arc-shaped support arm 121 . The second contact portion 13 protrudes above the flat support arm 122 . The fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com