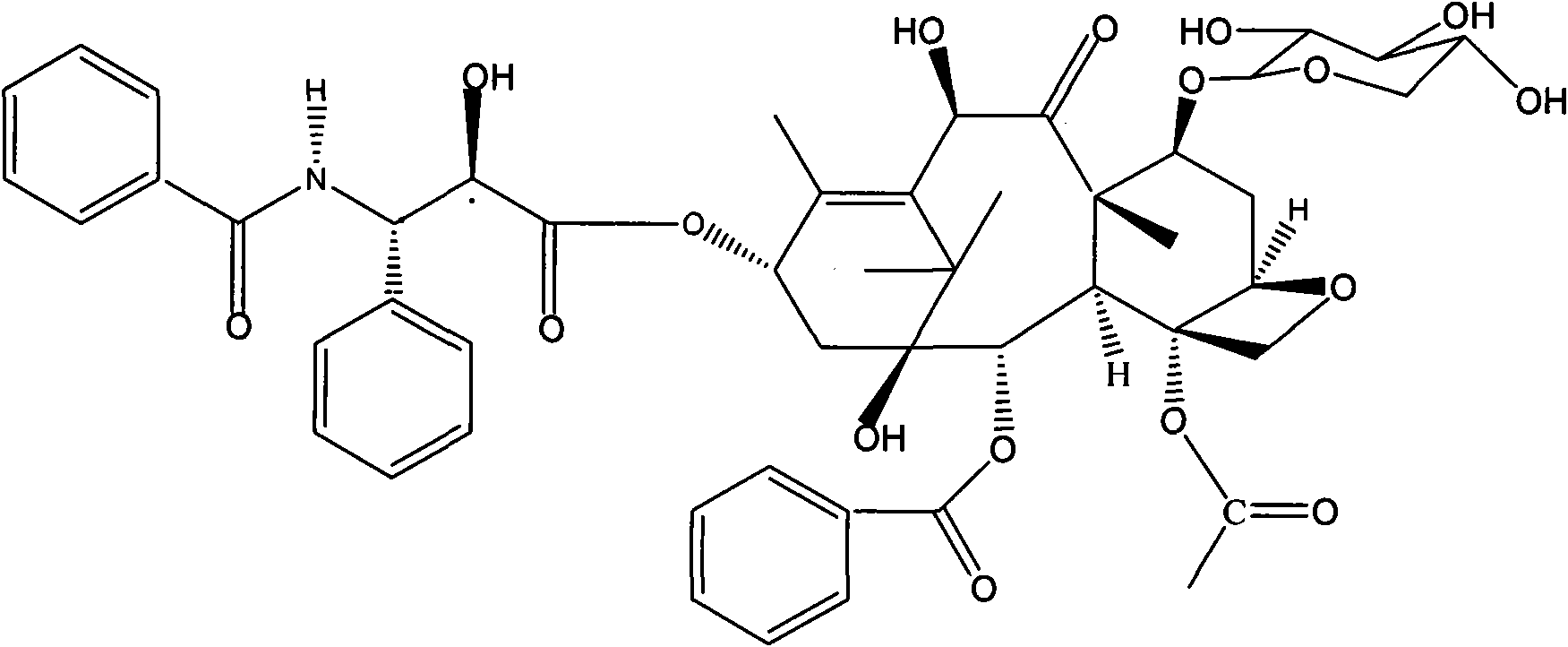

Method for extracting and purifying 7-xylose-10-deacetyl paclitaxel from taxus cuspidata

A technology of acetyl paclitaxel and yew, applied in chemical instruments and methods, separation methods, sugar derivatives, etc., can solve the loss of 7-xylose-10-deacetyl paclitaxel, long purification process, backward extraction process, etc. problem, to achieve the effect of simple and easy method, short cycle, efficient and reasonable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weigh 1000g of fresh twigs and leaves of Taxus chinensis (dry weight is 200g), add 2000mL of 50-60℃ warm water to extract twice, and then extract continuously twice, each time for 30min.

[0018] At the same time, 400g of macroporous adsorption resin AB-8 is packed into a column by wet method, and the liquid level is retained, and 4000ml of the extracted medicinal solution is passed through the adsorption column at a flow rate of 2400-3200mL per hour. Impurities were washed with 2BV of 30% ethanol, and then eluted with 6BV of 80% ethanol. The effluent was collected and concentrated to obtain a concentrate.

[0019] 200 grams of 300-400 mesh silica gel was applied to the column with chloroform wet method, and the eluate was concentrated to dry powder and mixed with silica gel in equal proportions, and purified on the silica gel column. When the volume ratio of the eluent (chloroform:methanol) was 12:1, 200 mg of crude 7-xylose-10-desacetyl-paclitaxel was eluted.

[0020...

Embodiment 2

[0022] Weigh 2kg of dried branches and leaves of Taxus chinensis, add 18L of warm water at 50-60°C to extract twice, and then extract twice continuously, each time for 30min.

[0023] At the same time, 4 kg of macroporous adsorption resin AB-8 was packed into a column by a wet method, and the liquid level was retained, and 36 L of the extracted medicinal solution was passed through the adsorption column at a flow rate of 24 to 32 L per hour. Impurities were washed with 2BV of 30% ethanol, and then eluted with 6BV of 80% ethanol. The effluent was collected and concentrated to obtain a concentrate.

[0024] 2kg of 300-400 mesh silica gel was applied to the column with chloroform wet method, and the eluate was concentrated to dry powder and mixed with silica gel in equal proportions, and purified on the silica gel column. When the volume ratio of the eluent (chloroform:methanol) was 12:1, 2 g of crude 7-xylose-10-desacetyl-paclitaxel was eluted.

[0025] The mobile phase in whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com